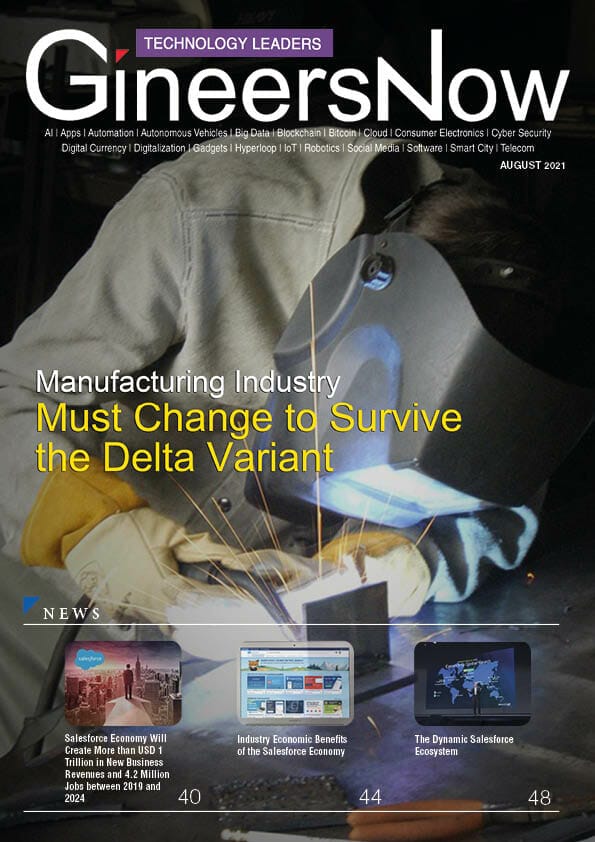

Manufacturing Industry Must Change to Survive Delta Variant Pandemic

Prior to the pandemic, Industry 4.0 technologies were already changing manufacturers’ processes. Now, adoption is dividing the haves and have-nots in terms of technology.

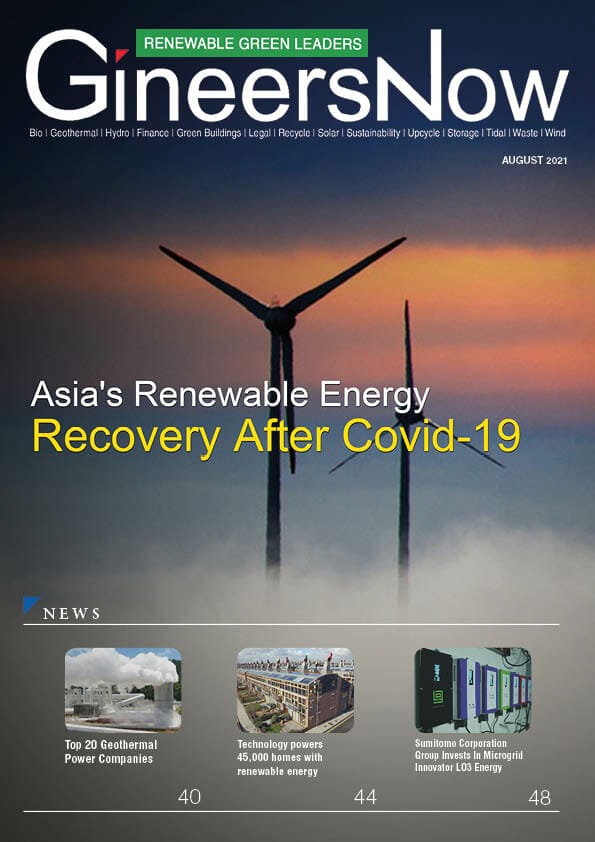

Even in areas of the globe where the early impacts of COVID-19 have begun to fade, severe dislocations seem likely to continue to be a reality for some time to come, with CEOs continually under new pressure. For example, in a recent McKinsey study of Asian manufacturers, problems with unexpected material shortages were cited as a frequent concern (45% of respondents), as were sharp decreases in demand (41%), and employee unavailability (30%).

Nonetheless, even before to the pandemic, volatility was becoming a buzzword among supply-chain and industrial executives. While companies adapt to the new normal, executives are concerned about the long-term impact of COVID-19 on production and supply networks.

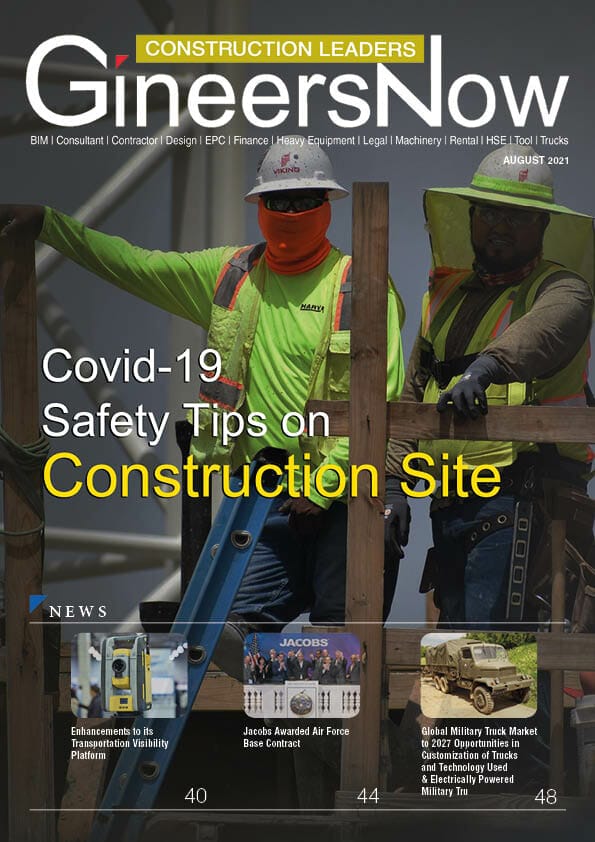

Most importantly, they are likely to be far more digital, as shown by the rapid response to the pandemic. Industry leaders are embracing Industry 4.0 solutions: 39% have adopted a nerve-center (or control-tower) strategy to improve end-to-end supply-chain transparency, and about a quarter are accelerating automation projects to address COVID-19-related labor shortages.

Industry 4.0—which encompasses connectivity, advanced analytics, automation, and sophisticated manufacturing solutions—was gaining traction prior to COVID-19, assisting businesses in transforming their operations in areas ranging from manufacturing efficiency to product customization, resulting in increased speed to market, service effectiveness, and the creation of new business models.

It is no surprise that the pandemic of COVID-19 has created worldwide humanitarian problems that will need a new kind of cooperation to solve. As companies resume operations in the new normal, they have a chance to envision a future characterized by digital, resilient operations.

Early examples demonstrate that businesses may begin their industry 4.0 transformation journey small and then grow rapidly—if they commit to Industry 4.0 transformation in alignment with their business environment and strategic goals and execute it utilizing a triple transformation strategy focused on business, technology, and organization.