Reinforced Concrete

It has long been the practice of civil engineers to use reinforcement bars in concrete structures. As what is taught in civil engineering’s reinforced concrete design, concrete holds the compressive forces in a structure while steel provides for the tensile loads.

They are the standard materials that make reinforced concrete suitable for buildings.

However, this might just change.

There’s a new suggested material that is cheaper and more abundant in nature, also proven to be stronger than the conventional reinforcing steel – it is a type of grass called bamboo.

“This has the potential to revolutionise our building industry and finally provide an alternative to the monopoly of reinforced concrete,” says Dirk Hebel, an assistant professor of architecture and construction at the Future Cities Laboratory in Singapore, who also worked at Swiss Federal Institute of Technology Zurich (ETH).

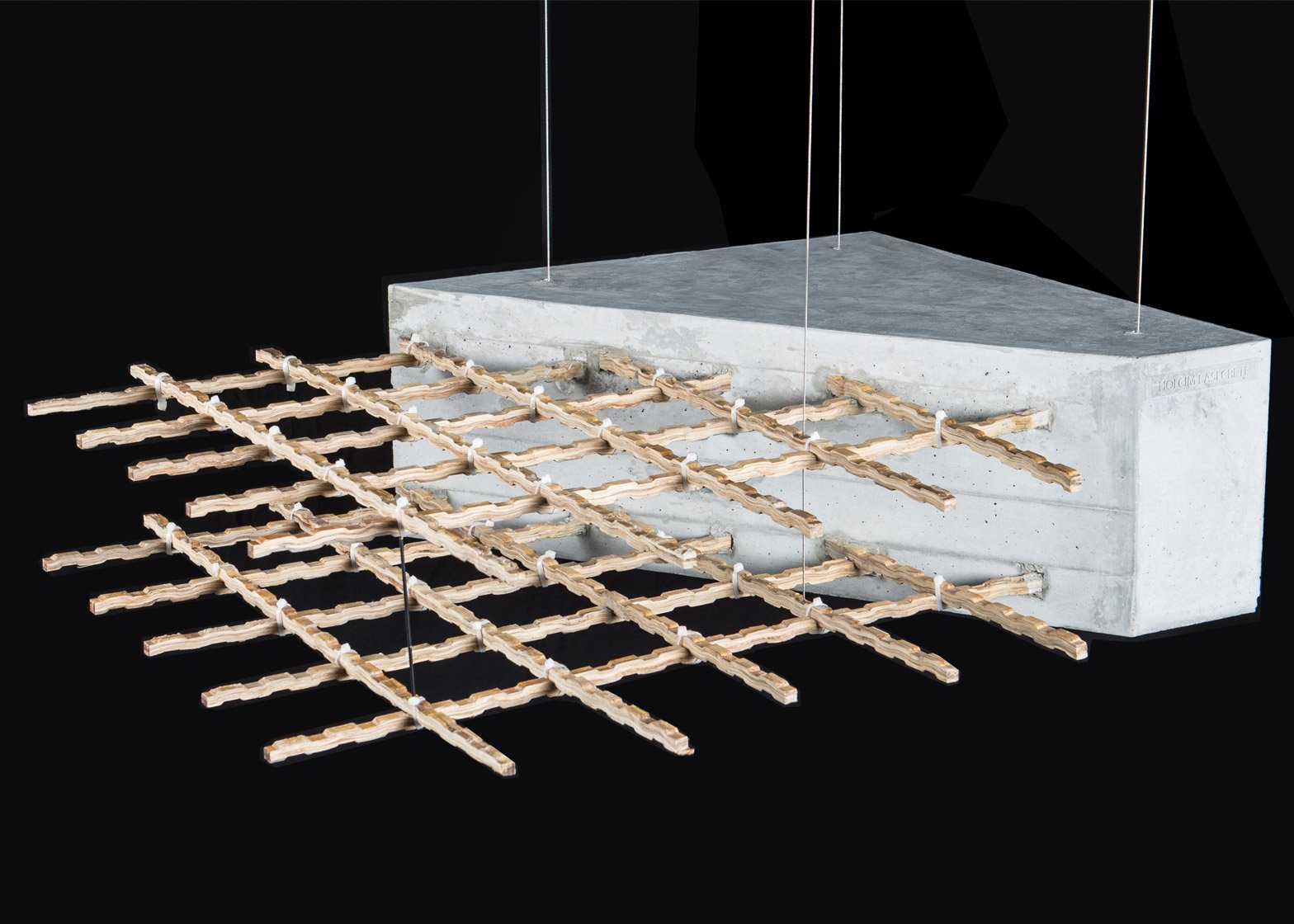

He spoke at the World Architecture Festival to introduce a new material he calls the bamboo composite material, which is made from bamboo fiber and organic resin.

It can be pressed into any shape, like rods resembling rebars, and then sawn or sanded like wood.

If the concern is tensile strength, Hebel guarantees that the material he and his team produced surpasses that of the rebars.

“We can produce a material that in terms of tensile capacity is better than steel. Our material is only a quarter of the weight of steel. In terms of strength to weight, it performs better than steel.

“The big advantage of a bamboo fibre is that it is 100 times cheaper than carbon fiber, but it has potentially the same strength,” he adds.

A research project which involves providing a more sustainable and affordable alternative to steel in developing countries, which by the way, consume most of the total steel (70%) and total cement (90%), has allowed Hebel to explore more of bamboo’s properties as a construction material.

In those same areas which are expected to have a high urbanization rate, the bamboo plant was noticed to be abundant.

Bamboo, in itself, is has extremely high tensile strength. It doesn’t require replanting after harvesting either unlike timber.

But instead of using the bamboo as it is for reinforcement, Hebel found a way to extract fiber from the grass, mix it with 10% organic resin, and make a moldable material that could replace the steel in reinforced concrete. It is water-resistant, non-swelling, and durable.

Tests involving concrete embedded with the bamboo composite material have been conducted at a laboratory in Singapore and it showed promising results.

“We had a breakthrough – our testing machine was not able to break the material,” Hebel shares.

The target application of this material is not really in high-rise buildings. According to Hebel, by theory it can be used for skyscrapers. But since 80% of all structures worldwide are one or two stories, he prefers to provide for that.

Now that he has provided a sustainable alternative for steel, Hebel now works in finding the same for concrete.

“Besides bamboo we do a lot of research into other materials and of course our aim is also to replace the concrete,” Hebel tells.

For that, he and his team have so far collaborated with Berkeley University to explore a non-cement-based concrete.

They are studying a biological-based material made of mycelium, commonly found in fungi. We do not know yet if that’s already what they are looking for.