Skin regeneration usually takes a long time to heal, so why not try skin repair as a solution?

There is now a functional human skin made by Spanish scientists that is made through 3D bioprinting. It is designed to be transplanted to patients or be used in research of testing of skin products in the cosmetic, chemical and pharmaceutical sectors.

In a world’s first, researchers from Universidad Carlos III de Madrid (UC3M), CIEMAT (Center for Energy, Environmental and Technological Research), Hospital General Universitario Gregorio Marañón, in collaboration with the firm BioDan Group, have successfully developed a proper human skin from a 3D bioprinter.

José Luis Jorcano, an author of the study and an engineering professor at UC3M, shared that this skin “can be transplanted to patients or used in business settings to test chemical products, cosmetics or pharmaceutical products in quantities and with timetables and prices that are compatible with these uses.”

The artificial skin works and looks just like the human skin, replicating all the natural layers and their functions. This is one of the first living human organs which are created with bioprinting.

Source: UC3M

Alfredo Brisac, CEO of BioDan group, tells the great benefits of this technology, “This method of bioprinting allows skin to be generated in a standardized, automated way, and the process is less expensive than manual production.”

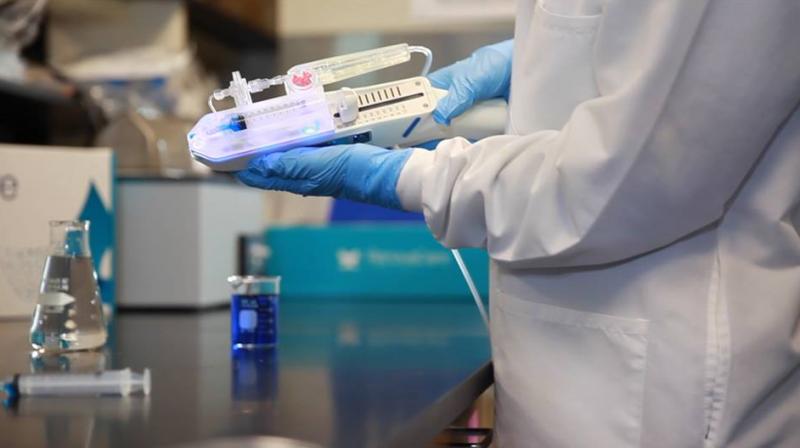

But unlike 3D printing which uses cartridges and colored inks, 3D bioprinters use, well, bioinks to create the skin. It has injectors with biological components.

“Knowing how to mix the biological components, in what conditions to work with them so that the cells don’t deteriorate, and how to correctly deposit the product is critical to the system,” says Juan Francisco del Cañizo, a researcher from the Universidad Complutense de Madrid.

The bioinks are patented by CIEMAT and licensed by the BioDan Group. Depositing them is controlled by a computer, which lays the ink on a print bed where the skin is formed.

There are two ways that this skin can be used: one, is to produce allogeneic skin, from a stock of cells, done on a large scale, for industrial processes; and two, is to create autologous skin, which is made to be personal out of the patient’s own cells, for therapeutic use, such as in the treatment of severe burns.

So far, this skin is yet to be approved by different European regulatory agencies as it is still under development.

Source: Phys.org