There’s a new breakthrough system that turns captured carbon emissions into baking soda. And it’s being performed by a chemical plant in India.

Located at an industrial port city, the Tuticorin Alkali Chemicals plant developed a technology that can convert 60,000 tonnes of CO2 emissions into baking soda and other chemicals in a year.

Researchers behind this remarkable conversion say that about 5 to 10% of coal emissions from around the world could be captured and used.

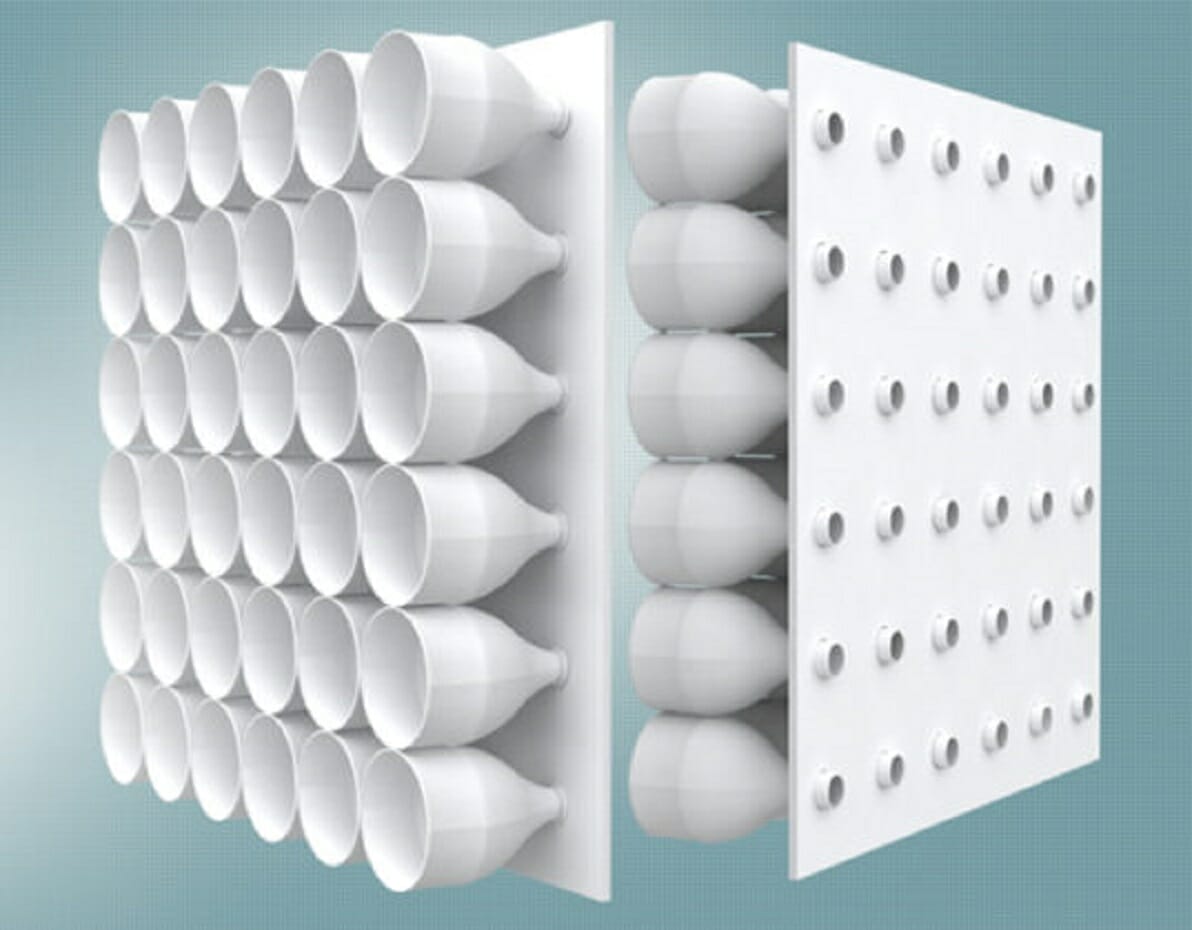

It works by having the CO2 emissions from the coal-fired boiler, which makes steam for the plant’s chemical operations, stripped out by a fine mist of a new patented chemical. A stream of CO2 is created and fed into the chemicals plant as an ingredient for baking soda.

That patented chemical catalyst – which uses a form of salt to bond with CO2 molecules in the boiler chimney – was developed by two Indian chemists under a company called Carbon Clean Solutions. However, they failed to get funding in their own country.

Thanks to the affiliation of the chemists’ company with the Institute of Chemical Technology at Mumbai and the Imperial College in London, they were able to get backing from the UK’s entrepreneur support scheme.

Using the technology entails great savings for the company. They say that the conversion tech needs less energy, produces less alkaline waste and allows the use of a cheaper form of steel.

The process by the Tuticorin Alkali Chemicals is not at all subsidized by the government. This means that it could be expanded commercially across other plants and industries, since the system might just be profitable and practical for others to use. Manufacturers of glass, detergents, and sweeteners could make use of the technology.

Aniruddha Sharma, CEO and Founder of Carbon Clean Solutions, shares that the company’s approach is to think realistically and partner with modest, low-risk enterprises as they build themselves up.

“So far the ideas for carbon capture have mostly looked at big projects, and the risk is so high they are very expensive to finance.

“We want to set up small-scale plants that de-risk the technology by making it a completely normal commercial option,” he adds.

However, the managing director of the plant, Ramachadran Gopalan, says that a solution that was sustainable wasn’t his goal.

“I am a businessman. I never thought about saving the planet,” he reveals through a BBC Radio 4 documentary. “I needed a reliable stream of CO2, and this was the best way of getting it.”

Gopalan tells that that operation now has almost zero emissions. He plans to install a second coal boiler and utilize its CO2 to synthesize fertilizer.

It’s important to note that the plant’s system is considered a carbon capture and utilization, instead of carbon capture and storage. This only means that the process does something with the captured carbon instead of merely storing it in a useless, dormant state.

This is only one of the many carbon capture technology in the field. Lord Oxburgh, former chairman of Shell, and now director and head of the UK government’s carbon capture advisory group takes delight with such.

“We have to do everything we can to reduce the harmful effects of burning fossil fuels, “ he tells BBC. “It is great news that more ways are being found of turning at least some of the CO2 into useful products.”