Set Up a Workshop: Step by Step

Want to DIY your garage or a small room into a workshop? This article will guide you through a step-by-step process in creating your perfect workshop!

Setting up your workshop is not only a fun experience but, also you can bring your dream workshop to life. Oftentimes, we rent places for our work but no matter how we decorate the place, the whole setup doesn’t seem to live up to our imagination of the workshop we want it to be. Doing it yourself is the perfect solution to this. By the end of this article, you will learn how to set up the workshop in your basement, garage, or any small room that fits your requirements.

Step 1: Understand Your Need

First, take some time to think about the purpose of this workshop. The size, design, layout, everything depends on what your workshop is going to serve. This will also determine the location of the workshop. Check out websites like woodworking toolkit to find everything you’ll need. Another very important factor to consider is whether you’d need an extension in the future. The workshop should be made in a place that has enough room to extend.

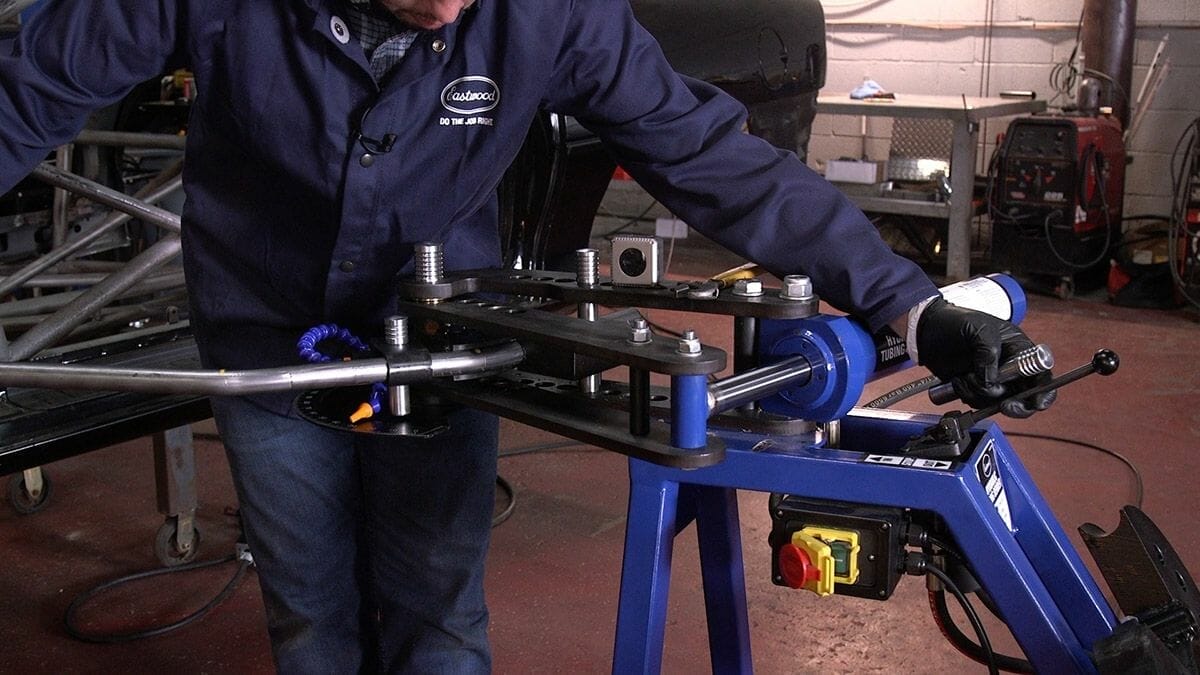

Step 2: Get your Tools

You will need the best socket set to power your lumber, saw, power drill, level, tape measure, screwdrivers, hammer, pliers, socket wrench, gloves, and protective gear for your workshop. These come with different tool measurements, can be very handy, and are always needed at home to fix things from time to time. So even if you have to buy these tools, they will be a great investment for future purposes. You can easily get these tools for just under $300 and if not lost, they will serve you a lifetime!

Step 3: Dust and Sawdust Collection

The dust has been associated with breathing problems and other respiratory diseases. So removing the dust is important. Now we all know how dusty a workshop can be from all the wood shavings. Nowadays, it is easy to get a dust collector installed for under a thousand dollars. This equipment involves flexible tubes that carry the dust to a central dist collector from where it can be cleaned.

Sawdust from the bandsaw needs other equipment used for cleaning up the dust underneath. A dust port is not enough for the clean-up. So another port is needed in addition to the dust port to ensure that all the dust produced can be collected.

You may use a vacuum cleaner instead to collect and clean all the dust, but it can collect only low volumes of dust and doesn’t provide full-scale filtration as dust collectors do.

Step 4: Size and Design

The size of your workshop will be determined by the number of power tools to be kept in the workshop. Typically, an ideal workshop is about 125 square feet, including the lumber storage area.

All equipment should be placed in a manner that you don’t bump or topple over any. There should be 3 feet distance between each machine. Your workbench should be 4 feet apart from other machines and must be spaced to easily incorporate a stool or stand comfortably by the table.

Design a layout of where to install each machine, so you can move freely. Having a layout ready will also save you from the hassle of moving the machines from time to time.

Step 5: Entrance

Since your workshop will contain machines and lumber, a spacious entrance will make it more feasible to move this equipment. Enough ventilation is crucial for workshops and sometimes, the windows alone can’t provide the ventilation needed. The entrance should be designed keeping all these factors in mind.

The entrance can change depending on the location of the workshop. If the workshop is in your basement or garage then you can design the entrance in one way; if it is in another room then the entrance would be different.

Step 6: Electric Amenities

Almost all the tools to be used in the workshop will require electricity. Hence, it is a crucial factor. Your workshop should have its separate sub-panel, also known as a Pony panel, that will meet all the electric requirements of the shop, from power outlets to lighting and running the machines.

It is advised to keep the power outlets at least 4 feet above the ground to ensure safety and get easier access. Use 220V machinery rather than the ones with lower volts to save electricity and install dedicated circuit breakers.

Step 7: Lighting

Since you will be working with machinery, proper lighting is important. Sure you can make use of natural sunlight while working during the day, but you need to put up lights if you’re working at night or the day isn’t very sunny! Place the machines in a way that the light doesn’t reflect directly on your eyes.

Fluorescent lighting is better and more affordable than incandescent lighting. While some lights need to be plugged in, others are wired permanently. Put up spotlights or lamps in the corners if needed.

Step 8: Storage Facility

You don’t want your tools lying all over the place. A workshop must have a good storage facility to store tools as well as unused timber. You can get wooden shelves and arrange tools according to their sizes or weights. You can also DIY a large holder to keep the lumber in one corner of the workshop. Furthermore, you can also incorporate cabinets as they are closed and hence, dust does not enter the tools.

Step 9: Workbench

Your workbench is the heart of your workshop, so it has to be firm and steady. Since you’ll be working on this table, it should be large enough to accommodate all tools and the height should be optimum to ensure that you can work comfortably.

You can easily buy workbenches or even make one yourself. For added benefits, you can incorporate a few shelves or drawers and a vise into your bench.

Step 10: Safety

Understand that working with machinery comes with danger. In order to be safe, you must follow the instructions that come with each machine. When you start work, concentrate and finish it. Clean everything and put your tools back to their respective shelves or cabinets.

Always keep your workshop dry and clean. Having electric wires and a wet floor can be extremely dangerous. Don’t forget to keep a fire extinguisher. It is very wise to install a GFCI receptacle to prevent excessive current flow which can cause accidents.

Remember to wear safety goggles and gloves while working. The goggles are shatterproof and will save your eyes from any wood shavings. The gloves will protect you from cutting your hands. Wear a mask even if you are not allergic to dust as overexposure to dust can create respiratory ailments.

Designing and creating your workshop can be a very tiresome experience, but it’s going to be worth it in the end. So what are you waiting for? Gather your things and let’s build that workshop you want.