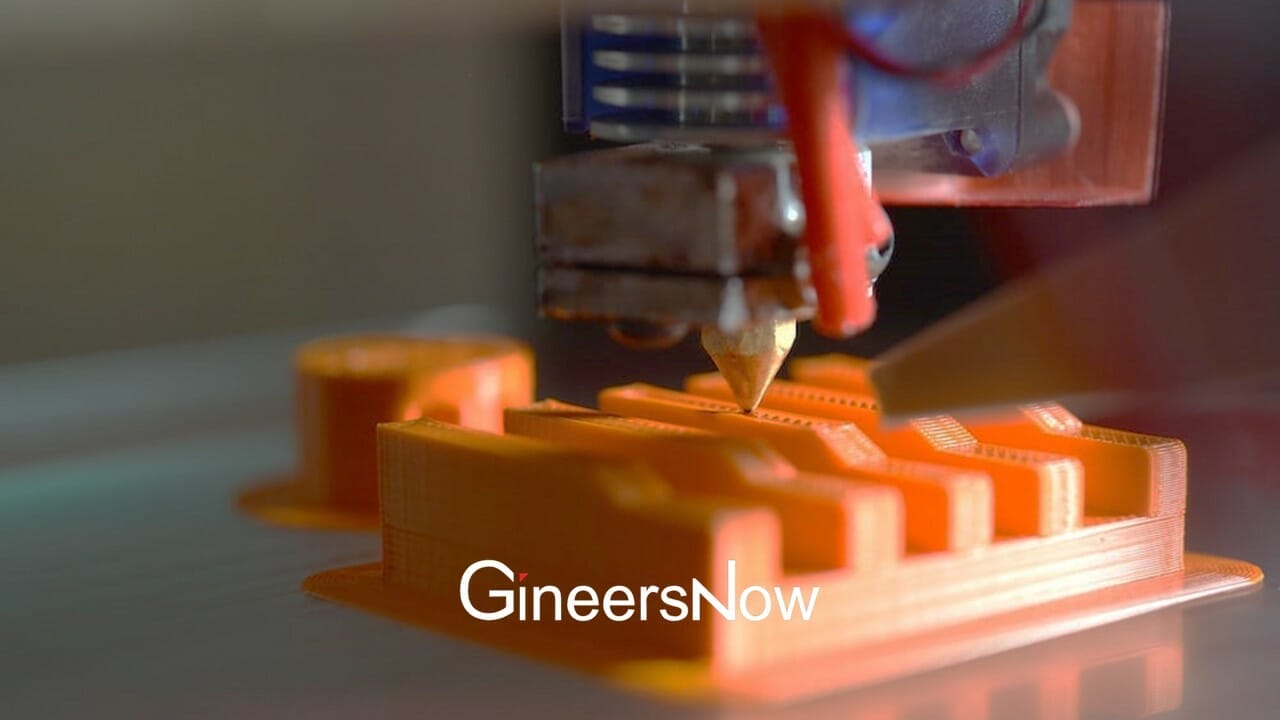

A team of researchers from 3 Institutions have developed a new 3D printing technique that allows objects to change shape when exposed to heat.

The team is comprises of researchers from Georgia Institute of Technology, Singapore University of Technology and Design, and Xi’an Jiaotong University in China. They have created the morphing objects by printing layers of shape memory polymers with each layer made to react differently to heat.

“This new approach significantly simplifies and increases the potential of 4-D printing by incorporating the mechanical programming post-processing step directly into the 3-D printing process,” explains Jerry Qi, professor in the George W. Woodruff School of Mechanical Engineering at Georgia Tech. “This allows high-resolution 3-D printed components to be designed by computer simulation, 3-D printed, and then directly and rapidly transformed into new permanent configurations by simply heating.”

Source: Tech Xplore

The New Method

The basis of the development of this 3D printed objects are from the past work that the team had done involving smart shape memory polymers (SMPs), which have the ability to remember one shape and morph into another programmed shape when exposed to heat. “The approach can achieve printing time and material savings up to 90 percent, while completely eliminating time-consuming mechanical programming from the design and manufacturing workflow,” said Qi.

To demonstrate the new object’s capabilities, the team had 3D printed several objects that could bend or expand quickly when dunked in hot water. These tests included a flower-shaped object whose petals will bend like a real daisy when exposed to sunlight, and a lattice shaped object that expands up to eight times its original size.

Source: Youtube, Georgia Tech

“Our composite materials at room temperature have one material that is soft but can be programmed to contain internal stress, while the other material is stiff,” said Zhen Ding, a post-doctorate researcher at Singapore University of Technology and Design. “We use computational simulations to design composite components where the stiff material has a shape and size that prevents the release of the programmed internal stress from the soft material after 3-D printing. Upon heating the stiff material softens and allows the soft material to release its stress and this results in a change – often dramatic – in the product shape.”

Future Developments

The researchers think that the new morphing 3D objects could enable a new range of product features. An example is is allowing a product to stack flat or roll during shipment and then expand when in use. They could also create a new line of technology that makes components respond precisely to stimuli such as temperature, moisture, or light to create space structures, deployable medical devices, robots, toys and other structures.

Article Sources: