6 Uses Of Steel Tanks In The Engineering Industry

Steel is widely used in the engineering industry. It’s one of the most preferred fabrication materials because it’s non-corrosive as well as heat and fire-resistant. Its non-porous surface makes it easy to clean and sanitary to use. In addition, steel is durable and recyclable, making it a sustainable and cost-effective solution for various projects.

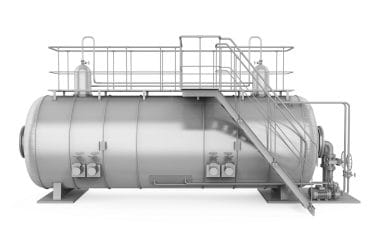

It’s instrumental in the process engineering field in the form of steel tanks. You may recognize the latter as towering cylindrical structures fitted with nozzles and monitoring instruments. Used as processing equipment, they’re crucial to creating everyday essentials such as food, beverages, medicine, cosmetics, petroleum, and energy.

Uses Of Steel Tanks

Owing to their valuable properties, stainless steel tanks have various applications in the processing industry. They compromise a wide array of processing equipment, such as kettles, mixers, boilers, or receivers. Stainless steel tanks can also have additional functions depending on what industry they are used.

For those who are curious about what they are and what they do, you can find several uses of steel tanks below. In addition, those interested in purchasing one can see that stainless steel tanks can be customized to perform the following functions.

- Storage Units

Steel tanks, particularly those made with stainless steel, are valuable for holding various substances in the processing industry. They are used as temporary or permanent storage units for food, water, chemicals, gases, and other bulk materials.

Industries prefer stainless steel because it can contain large volumes of liquids and gases without succumbing to rust or contaminants. For those planning to start their own processing business, a stainless steel tank is necessary storage equipment.

Stainless steel tanks can be oriented horizontally or vertically, and they may even be customized to meet certain specifications. Most tanks are stationary, while others are suited for easy transport. You can check out the price of a new or look for stainless steel tank for sale to see if they are a suitable solution for your needs while staying within your budget.

- Mixing/Blending Chambers

Manufacturing plants also use stainless steel tanks to blend materials. Industrial kettles and boilers mix substances to create soups and sauces, while multi-compartment tanks combine meat and vegetables to form processed food and snacks. They can also cool fruit juices and other beverages.

Steel tanks are also equipped with agitators and mixing heads. These components allow easy stirring while agitators hasten the mixing process. Aside from these, food-grade tanks also regulate temperature, so food retains its flavor and prevents unwanted bacteria growth.

Mixing and blending chambers follow industry specifications and standards to ensure that food and beverages are processed using sanitary practices.

- Bio Reactors

Apart from storage and mixing, stainless steel tanks can also function as bioreactors. These tanks are widely used in the pharmaceutical industry. They are also common in research laboratories.

Stainless steel tanks act as an apparatus to grow bacteria, plant, and animal cells to produce drugs, vaccines, and other valuable products. The tank maintains ideal temperatures, pH, and oxygen levels to synthesize organisms. Process engineers then harvest bacteria, plant, or animal culture and transform them into healthcare products or aid in scientific advancements.

- Fermenter

Stainless steel tanks also serve as controlled environments to produce acids and alcohols. They can grow yeast, fungi, or bacteria to aid the fermentation process. Steel tanks are preferred storage containers across distillation facilities for wine, beer, and other spirits.

Aside from fermenting tanks, industrial kettles, heating, cooling, and conditioning tanks are also involved in beer brewing. Beverage processes often include several pieces of equipment to finish the entire process.

- Sterilization Tunnels

Aside from producing various pharmaceutical products, stainless steel tanks also act as sterilization tunnels. Stainless steel tanks are equipped with temperature controls that heat the glass bottles to remove contaminants that may remain even after rigorous washing. After which, they are then transferred to a cooling chamber to complete the sterilization process.

Sterilization tunnels employ heating and cooling processes to eliminate bacterial growth on bottles and other containers. They ensure bottles are safe and sanitized before capsules, pills, powder, or liquids are poured into containers.

- Pressure Tanks and Vessels

Steel tanks not only process food and liquids but can also contain gases or vapor. Pressure tanks and vessels hold oil or gases that require heating or cooling. They are often customized with cooling jackets and double walls to meet safety regulations and prevent spills or leaks.

Pressure tanks and vessels are standard in the energy industry, such as in oil depots and refineries. A critical difference between pressure tanks and vessels is the maximum allowable pressure (MAOP) which is 15 PSI for tanks and a maximum of 3000 PSI for pressure vessels.

There are three types of pressure vessels: storage vessels, heat exchangers, and process vessels. Storage vessels are designed to handle specific materials and their temperatures. These vessels are commonly used to store propane, ammonia, butane, chlorine, and LPG.

Heat exchangers process waste gases by allowing fluids to pass through heated tubes while process vessels perform heating and cooling, blending, or separation methods to create products.

- Biodigesters

Steel tanks have wide applications in the energy industry. Besides storing petroleum products, they can also aid in renewable energy production. They are helpful in biogas production, where stainless steel tanks create controlled environments in the same way bioreactors do for food and pharmaceutical products.

Conclusion

Steel tanks have broad applications in process engineering because of their ability to withstand rust, dirt, and temperature changes. They compromise processing equipment that has various purposes.

Compact tanks serve as mixers or blenders for food and beverages, while larger columns act as bioreactors and fermenters. These cylindrical structures also double as sterilization chambers for medical containers. In the energy industry, pressurized tanks and vessels store petroleum products and even aid sustainable energy efforts.

Steel tanks are versatile equipment, and they have several advantages to your processing business. Buying used or new stainless steel tanks can serve various purposes and industries. You should consider them for your business, especially if you’re in the engineering sector.