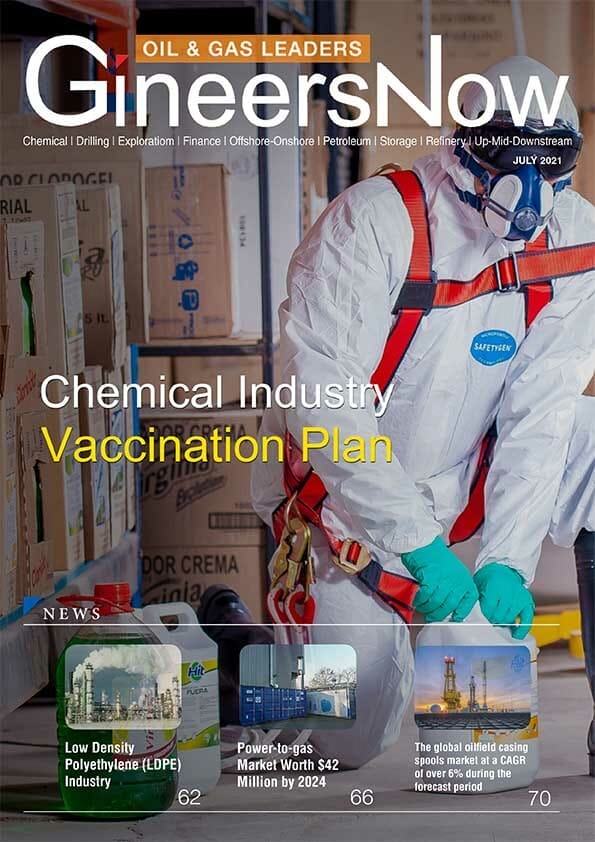

Chemical Industry’s Vaccination Plan

With global demand for COVID-19 vaccinations outstripping global supply, dissatisfied public and politicians want to know how they can obtain additional vaccines faster. Unfortunately, it is not as easy as it looks. COVID-19 vaccine manufacturers rely on everything going well as they ramp up production to hundreds of millions of doses — and every minor hitch may result in a delay. Several of its components have never been manufactured in the quantities required.

For instance, raw ingredients for Pfizer and Moderna vaccines are in short supply. The manufacturing process begins with the growth of something called “plasmids” — self-contained bits of DNA — that hold instructions for creating the vaccine’s genetic material.

Following that, specialized enzymes derived from bacteria are introduced to initiate a chemical process that assembles the mRNA strands. The strands are then packed in lipid nanoparticles, which are tiny bubbles of fat derived from petroleum or plant oils. The fat bubbles within the human body preserve the genetic material and aid in its delivery to the cells.

Unfortunately, just a few businesses specialize in manufacturing these substances, which were formerly sold by the kilogram. However, they are now required by the metric ton – a 1,000 times increase. There are a number of corporations that manufacture these enzymes, nucleotides, and lipids, but they may not be of a quality suitable for human consumption. It might be a grade that is suitable for human consumption or research on animals but not for injection into a human being.

Meanwhile, adenovirus vaccines like J&J and Moderna uses a little more conventional form of cell growth in huge tanks known as bioreactors. This process takes time, and even the tiniest contamination may ruin a whole batch. Due to the fact that the process involves living creatures, it may feel more comparable to cultivating plants. Improving yield is a combination of art and science, as the manufacturing process is based on biological processes.

The vaccine developers are always looking for ways to streamline manufacturing without sacrificing quality. Pfizer is now providing six doses each vial rather than five, while Moderna has requested authorization to increase the number of doses in each of its vials from ten to fifteen.

Despite the likelihood of intermittent bottlenecks and delays in the future months, firms appear to have optimized their supply chains to the point where they are confident in their ability to achieve current production objectives.

Click below to read the magazine