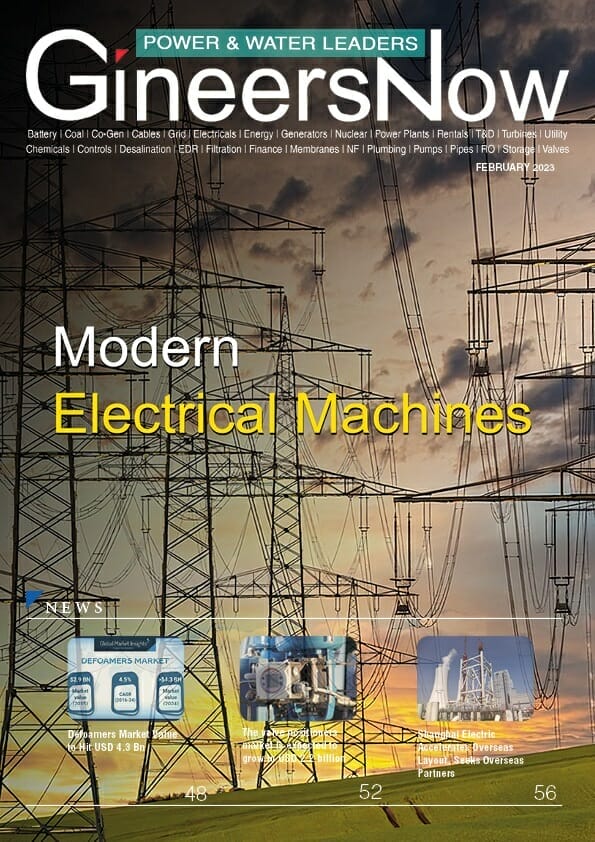

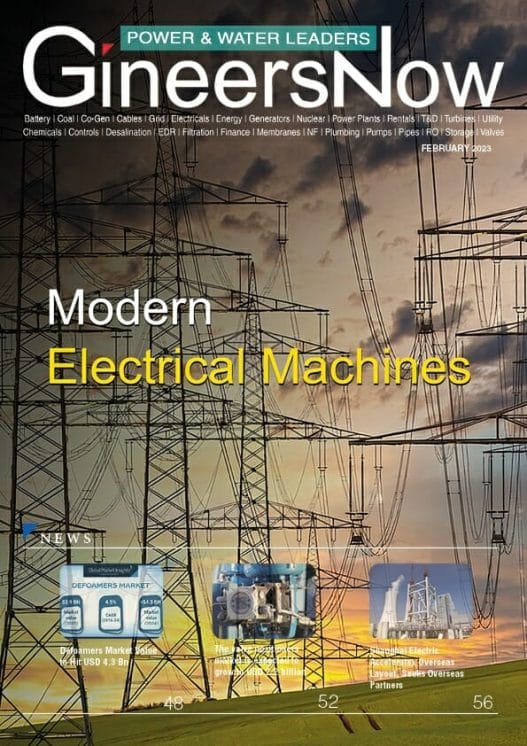

Discover how to design modern electrical machines and unlock the next level of optimization. Learn the latest trends, tools, and tips to stay ahead of the curve.

As technology advances, the need for advanced electrical machines increases. Designers and engineers must now optimize these machines for efficiency and consumer satisfaction. With ever-evolving tools and techniques, designing modern electrical machines is becoming increasingly complex. Today’s designers must understand the latest developments in engineering and computer science to develop modern electrical machines that meet customer needs.

Optimizing Modern Electrical Machines

Modern electrical machines are widely used in various industrial and domestic applications. Optimizing these machines is essential for efficient performance and reduced energy consumption. This article will cover the fundamentals of modern electrical machine optimization and discuss some of the available techniques that can be implemented to maximize their efficiency.

Optimizing modern electrical machines begins with understanding their components and design features, such as magnetic circuits, winding configurations, insulation systems, cooling systems, and drives. It is important to consider the system operating conditions when optimizing these machines; this includes temperature and load requirements and environmental factors such as dust and moisture. Other optimization considerations include selecting materials with high thermal conductivity for stator cores or improving cooling methods with air or liquid-cooled systems.

Theory: Electromechanics

Modern electrical machines are the backbone of our industrialized world. A detailed knowledge of electromechanics is essential to understand how they work and designing effective new models. Electromechanics studies the relationship between electric currents, magnetic fields, and mechanical forces in modern electrical machines.

The theory of electromechanics has been used extensively to develop new machines with improved efficiency and power output for use in various applications. It is also used to analyze existing designs to identify areas where improvements can be made. Understanding how electricity interacts with mechanical components helps engineers design more efficient electrical systems that reduce energy consumption and cost. The electromechanical theory also aids in predicting potential failure points before they occur so that corrective action can be taken quickly if necessary.

Benefits of Modern Electrical Machines: Improved Efficiency

Modern electrical machines offer numerous benefits for businesses, industries, and households. One of the most notable advantages is improved efficiency. With modern electrical machines, energy consumption is significantly reduced while output is increased. This means that more energy-efficient systems are now available to handle any job necessary with great accuracy and at a much quicker rate than traditional models.

Efficiency improvement has been further enhanced through new technology, such as the development of variable speed drives. This allows motors to be operated at different speeds depending on required load levels and reduces the amount of energy wasted during operation, which lowers utility bills in the long run. Additionally, users can also benefit from smart grid technologies that enable better monitoring and control over electricity usage and predictive maintenance capabilities that help reduce costly machine breakdowns due to a lack of upkeep or servicing.

Modern Electrical Engineering: Advanced Automation

Modern electrical engineering has become a powerful tool for automation and control in today’s world. As modern technology continues to evolve, so does the field of electrical engineering. Using the latest electrical engineering techniques, it is now possible to program and automate large-scale processes with relative ease.

The advancement of contemporary electrical engineering has opened up new opportunities in automation and control. Automation systems are now capable of performing complex tasks with minimal human intervention. This allows companies to streamline operations, increase efficiency, and reduce costs by automating tedious tasks that would otherwise require manual labor. Modern electrical engineering also enables greater access to real-time data and analytics, allowing businesses to make more informed decisions faster than ever before.

Design Considerations: Component Selection of Modern Electrical Machines

Component selection is an integral part of designing any modern electrical machine. It is essential to have a thorough understanding of the available components and potential applications and limitations to make an informed decision when selecting the right component for a particular machine.

When it comes to modern electrical machines, component selection should not be taken lightly; there are numerous factors that must be considered to ensure that a machine operates safely and efficiently. The size and weight of the component should be taken into account as this will affect how easily it can be carried or installed; likewise, its ability to withstand extreme temperatures and vibrations must also be assessed. Furthermore, its power rating should match the required output voltage for optimal performance – too high or low will result in reduced efficiency or even damage.

Challenges in Designing Modern Electrical Machines

Designing and constructing modern electrical machines is a challenging but rewarding task. It requires insight into the various components of an electrical machine, such as its stator, rotor, and other parts. Furthermore, due to technological advances and changes in the industry landscape, engineers must consistently be aware of new trends and challenges when developing these machines.

The design process begins with understanding the application requirements of the specific machine so that it can meet the desired performance criteria. This includes considering factors such as efficiency, power rating, and cost constraints for each project. Additionally, designers must consider traditional methods for designing electrical machines and recent developments in cutting-edge technologies to create innovative solutions suitable for a given application.

Finally, modern electrical machines may require special attention during testing and validation stages to ensure safety standards are met throughout their service life.

Testing and Validation of Modern Electrical Machines: Virtual Prototypes

Modern electrical machines are essential to the modern world, powering everything from household appliances to large industrial systems. To ensure that these machines operate safely and efficiently, testing and validating them before being placed into service is important. To do this effectively, engineers have developed virtual prototypes that can simulate the conditions in which a real-world system would be used. This allows for testing complex designs without the need for physical prototypes and helps reduce costs while ensuring quality results.

Virtual prototyping has become increasingly popular over the last decade due to its ability to simulate various conditions with greater accuracy than traditional tests could provide. It also allows engineers to consider different aspects such as noise level, thermal restrictions, vibration levels, and other environmental factors that are important for determining a machine’s performance under real-world conditions.

Efficiency Improvements of Modern Electrical Machines

Modern electrical machines are a cornerstone of modern industry, allowing for increased efficiency in many different industries. They have come a long way since their invention centuries ago and continue to improve with technological advancements.

The improvements in electrical machines have made them more efficient than ever before. With better materials, improved designs, and faster technologies, these machines can now handle higher power requirements while using less energy. This benefits business and consumers who don’t want to waste energy while using their appliances.

The latest advancements in modern electrical machines also include features such as digital monitoring systems that can detect potential problems early on before they become major issues. Additionally, new safety features help protect workers from common risks associated with working near high-powered machinery.

Automation and Control of Modern Electrical Machines

The automation and control of modern electrical machines have revolutionized the industry. With advancements in electrical engineering and computer technology, machines can now complete tasks more efficiently and accurately than ever before. This has provided various applications, from industrial processes to consumer electronics.

Modern electrical machines allow for precise and diverse control over parameters such as speed, temperature, pressure, and current. Automation systems can be programmed to monitor conditions in real-time to protect against faulty operation or machine breakdowns. Additionally, automated safety features can be built into a system that will alert personnel when certain conditions become unsafe or exceed certain operational limits. In addition to these practical benefits, automation also makes it easier for workers to quickly adjust their workflows without needing manual oversight or intervention.

Cost Reduction Opportunities of Modern Electrical Machines

In the electrical industry, cost reduction is a major priority. With increasing competition and tighter profit margins, companies must look for ways to reduce operating costs. Modern electrical machines provide numerous opportunities for businesses to decrease their expenditures without sacrificing quality or reliability.

Technological advancements have made using electrical machines even more attractive than before. New materials, increased efficiency ratings, and improved performance all contribute to significant savings over time. Automation capabilities allow businesses to streamline processes while minimizing labor costs and energy consumption. Additionally, many modern electrical machines come with built-in monitoring systems that can quickly detect breakdowns and alert maintenance personnel when issues occur, resulting in faster repairs and less downtime.

The overall cost savings from using modern electrical machines can be considerable if implemented correctly by knowledgeable professionals.

The Financial Impact of Designing Modern Electrical Machines for Optimization

Modern electrical machines are at the forefront of optimization projects worldwide. As businesses continue to look for ways to maximize efficiency, designing modern electrical machines is proving to be a valuable tool in helping them achieve their goals. The financial impact of this innovation is being felt across many industries and sectors as companies take advantage of its capabilities to boost productivity and lower costs.

By leveraging the latest technology, businesses can create powerful new machines that offer superior performance while cutting power consumption. These modern electrical machines can help reduce operational expenses while also increasing revenue. Additionally, they can provide more accurate measurements, faster response times, and improved reliability compared to traditional models. Furthermore, the long-term cost savings from using these efficient devices will benefit businesses financially and environmentally.

Read GineersNow Power & Water Magazine for FREE

Editor’s Note

Learn how to design modern electrical machines for increased efficiency, safety, and performance. Discover the next optimization level and get the most out of your electrical system.

The field of electrical machines is ever-evolving and provides incredible potential for optimizing performance. By designing these machines differently, we can make them more efficient, reliable, and cost-effective. Technological advancements make the need to design modern electrical machines increasingly important. This article will discuss the process of designing modern electrical machines and the methods used to optimize their performance. It will also explore the challenges of such an endeavor and how to overcome them.

Electrical machines are capable of more than ever before. With the advent of new technologies, engineers have found ways to optimize their designs for better performance and efficiency. Designing modern electrical machines is no easy task, however. It requires an understanding of the physics behind them and creative problem-solving skills to make sure they meet all the necessary requirements.

Optimizing design has become even more important in today’s world as energy conservation takes center stage. By using advanced optimization techniques like genetic algorithms or particle swarm optimizers, engineers can design high-efficiency electrical machines with minimal effort and cost. These methods can be used to determine the best possible combination of components that will work together most efficiently in a given environment. Additionally, they can help identify areas where improvements can be made to optimize performance further and reduce energy consumption.

Modern electrical machines have revolutionized our operations, giving us power and a greater understanding of electricity. They have allowed us to build stronger and more efficient motors, which can be used in countless applications. With the help of electrical machines, we can now create smarter, safer, and more efficient products than ever before. We can produce energy faster and more efficiently than ever before as well.

Final Thoughts: Modern Electrical Machines

In conclusion, modern electrical machines are arguably one of the most important developments of the 20th century. They have allowed for a level of efficiency and productivity previously unimaginable, and their potential for further advancement is limitless. Electrical machines have revolutionized countless industries, from transportation to communication, and their continued development promises to bring about even more amazing advances in the decades to come.