What Does a Pneumatic Cylinder Do?

In industrial applications where automated machines need to be controlled by linear motion, pneumatic cylinders are used. These devices use the power of compressed gas to produce mechanical force. Below, we’ve discussed all you need to know about pneumatic cylinders, including the working principles, design standards, selection criteria, and everything in between.

What is a Pneumatic Cylinder?

A pneumatic cylinder is a mechanical device that utilizes compressed air to move a piston, and in the process, the compressed air energy produces linear motion. Depending on the operating principle, pneumatic cylinders can be classified into two types: single and double-acting pneumatic cylinders. We shall discuss these two types in detail in the later sections.

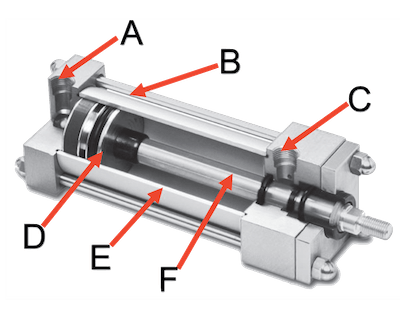

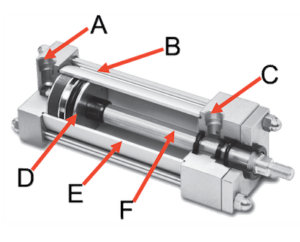

Pneumatic Cylinder Parts

A double pneumatic cylinder is made up of: cap-end port (A), rod end port (C), tie rod (B), piston (D), barrel (E), and piston rod (F), while a single pneumatic cylinder has either a cap-end port or a rod-end port (not both). Also, the spring is behind the secondary motion in a single-pneumatic cylinder. Control valves are used to channel compressed air towards the extended port at the same time opening the retract port to the atmosphere.

Pneumatic Cylinder Working Mechanism

The working mechanism of pneumatic cylinders varies based on their design and specific applications. Here’s a breakdown of the working principles of the two types of pneumatic cylinders identified earlier.

Double-Acting Pneumatic Cylinder

When compressed air enters through the cap-end port, it applies pressure on the piston and pushes it forward, increasing the piston rod’s length. As a result, the air is forced out of the rod-end port. To withdraw the piston rod, the rod-end port permits compressed air to enter, forcing the air out of the cap-end port.

Apart from allowing full user control, double-acting pneumatic cylinders have longer piston stroke lengths, plus it produces a constant output force. And due to its profound output force, it’s not advisable to use double-acting pneumatic cylinders in situations that demand a base position.

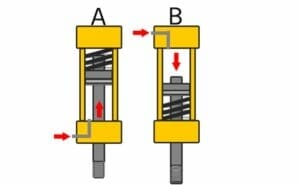

Single-Acting Pneumatic Cylinder

Similar to double-acting pneumatic cylinders, single-acting pneumatic cylinders utilize compressed air to drive the piston. A mechanical spring is responsible for retracting the piston in the opposite direction. Since pneumatic cylinders have a base position, they are helpful in fail-safe scenarios. There are two versions that can be seen in Figure 2: normally extended (A) and normally retracted (B). A major drawback of using single-acting pneumatic cylinders is their inability to produce consistent output force throughout the piston stroke.

Pneumatic Cylinder Design Standards

Pneumatic cylinders are designed to adhere to ISO standards; hence they can be used interchangeably with products and product parts of different manufacturers. Based on the unique application, mounting dimensions, piston-rod characteristics, etc., there’s always some standard dimension to suit your needs. Here are some of the common design standards.

Round ISO – 6432 (8-25) mm

Also known as mini air cylinders or round cylinders. They are single rod pneumatic cylinders that contain bores within the 8mm and 25mm range. The maximum pressure is usually 10 bars, but this pneumatic cylinder standard lacks a manual damping adjustment. ISO 6432 finds application in automation systems in laundry appliances, bottling, diagnostic instrumentation, and commercial kitchens.

Profile ISO – 15552 (32-320 mm)

ISO 15552 features mounting styles, mounting dimensions, piston rod characteristics, and bore sizes designed to fit into single and double rod pneumatic cylinders. They can operate up to a maximum of 10 bar working pressure. Additionally, ISO 15552 comes with an adjustable cushioning designed to realize a perfect dampening. Generally, ISO 15552 is suitable for general automation systems.

Compact ISO – 21287 (20-100 MM)

This ISO standard applies to single-rod compact pneumatic cylinders that support up to 10 bar working pressure. Pneumatic cylinders in this category are often compact and lightweight, but they lack adjustable cushioning. They are ideal for applications with limited space.

Rodless Cylinders

Just like pneumatic cylinders, rodless cylinders utilize compressed air to carry a load in a linear path. However, unlike pneumatic cylinders, rodless cylinders carry the load along with the piston instead of relying on an output force to pull or push the load. These cylinders find application in loading, web cutting, lifting, and material handling.

Cushioning

Since the fast movement of the pneumatic cylinder can cause shock when the piston hits either the cap-end port or rod endpoint, cushioning is necessary to help protect components from wearing out, transmitting vibrations, and producing unnecessary noise. Additionally, cushioning wards off the piston from rebounding off the rod-end port. There are multiple ways of cushioning, including flexible shock absorbers, adjustable pneumatic cushioning, and self-adjusting pneumatic cushioning.

Pneumatic Cylinder Accessories

Pneumatic cylinders come with some accessories that allow them to work optimally in various applications and environments. Here are some of the standard accessories:

- Piston position feedback – sensors are usually mounted on the pneumatic cylinders body to send position feedback to the piston in the case of automated machinery.

- Pneumatic grippers – typically made up of two or three fingers controlled by an internal pneumatic cylinder. They utilize compressed air to operate the fingers.

- Mounting accessories – Depending on the ISO standard of the pneumatic cylinder, mounting accessories are designed for mounting pneumatic cylinders.

Choosing a Pneumatic Cylinder

When choosing a pneumatic cylinder, there are a couple of factors you want to consider. First, you should know that the force generated from an input air pressure is directly proportional to the diameter of the pneumatic cylinder. You should also factor in the length of the stroke to determine how far the piston rod can extend and retract. Additionally, you should pay attention to the cushioning to protect the pneumatic cylinder and prevent the piston rod from rebounding. Depending on the purpose of the pneumatic cylinder, the pressure output of the cylinder should also be determined.