5 Reasons To Outsource Laser Cutting Services

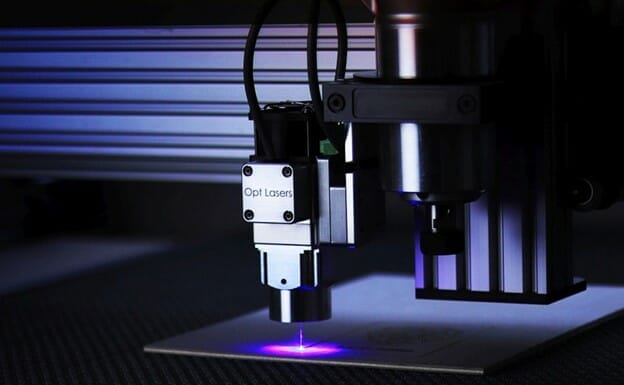

Laser cutting is the process of using a laser machine to cut various materials. It delivers excellent results with incredible precision. Every business, big or small, uses laser cutting for several reasons. Laser cutting is used for a range of activities, from printing cake toppers and drink coasters to creating stylish signage.

Before you start making quality laser cut components, there are a few things you should consider. The majority of businesses that outsource a laser cutting service have reasons for doing so.

So, why do businesses outsource laser cutting? Is it wise to outsource these processes? With these questions in mind, this article will outline the main reasons why businesses outsource laser cutting.

1. Quality Is Of High Standard

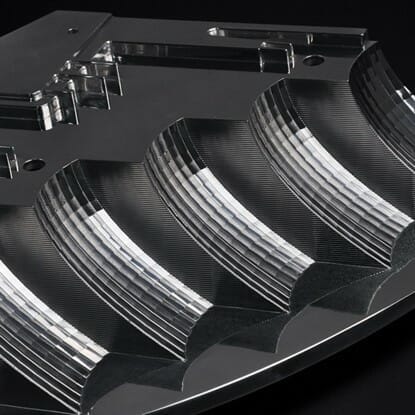

The quality of a laser-cut component is without a doubt the most significant reason why businesses outsource these services. Making high-quality laser-cut components takes time and experience. Laser-cutting companies likely developed comprehensive knowledge from creating laser-cut parts for customers from different industries. Your partnership with them gives you direct access to a team of professionals who can help you choose the right material, cut components to your exact specifications, and even examine your computer-aided design (CAD) files for accuracy. With a quick turnaround time and no need to stock material, it’s easy to understand why outsourcing laser cutting and custom CNC machining service is a good idea.

2. It’s Cost-Effective

Buying laser cutting equipment can be very costly. This can affect your bottom line and force you to raise prices, making your products less marketable and competitive. Moreover, if you own a computer numerical control (CNC) cutting machine, you are also responsible for its regular maintenance and operator training. Inability to achieve either of these conditions may result in equipment downtime and increased expenditure.

On the other hand, outsourcing to another sheet metal or laser cutting business means hiring a company that has already paid these expenses. They will probably be working with other clients, including yourself, so costs can be shared. This will also help you better manage cash flow and accounting.

3. It Could Speed Up Production And Increase Output

Outsourcing the cutting process allows your workers to work on other parts of the production or manufacturing process. The components you need will be delivered to your business pre-cut and ready to use. This could help you focus on improving your efficiency, selling more products, and raising your business’s profit.

Moreover, scaling up can be challenging when the time required to complete the order takes longer as you acquire new machinery or employees.

Outsourcing enables you to create more parts in the same amount of time while reserving your core resources for the proprietary work that generates the most revenue for your organization. It’s a good solution to scale quickly and increase revenue without greatly affecting your overhead.

4. They Use Cutting-Edge Equipment

By outsourcing laser cutting, you are choosing to work with cutting-edge technology and the best equipment. They are completely equipped with the latest equipment, resulting in superior quality and value. Using the latest technology ensures the best outcomes for your project.

5. Buying Your Own Equipment Takes Up A Lot Of Space

Laser cutting machines have become smaller as technology advances. But some businesses require large professional machines for their materials. If you can somehow afford the setup, keeping the laser cutting machines can still be a hassle.

These machines can take up a lot of floor space, which isn’t always an option for small businesses.

How Can You Pick The Best Laser Cutting Service?

To begin, contact several potential service providers and compare costs, timelines, and delivery performance.

However, another key thing to consider is location. In most circumstances, a laser cutting service nearer to your business is preferable to reduce delays and transportation costs.

Try to measure your possible supplier’s capabilities and workload. Ensure they can process the kinds of materials and thickness required. Examine the usual service level. Delays are inevitable if they are overloaded. They will also be less flexible if you need to adjust your order quantity at the last minute.

Look for laser cutting companies that have a good reputation and have been in business for a long time. A reputable and competent company assures you of a professional and reliable service.

Look for a company that responds quickly to your inquiries and is responsive to your demands as a possible customer. Your project will more likely be properly managed if the company replies quickly and attentively.

Check out the company’s services after validating their industry experience. Are the services they offer what you’re looking for? What can they work on? What other services do they offer aside from laser cutting? These factors and questions can lead you to the best laser cutting service for your company.

Conclusion

Outsourcing laser cutting can benefit your business in many ways. It can save you money, help you maintain high standards, and make running your company easier. Weigh the benefits of outsourcing to see whether it is a good idea for your business.