Regardless of the amount of technical knowledge you have about electrical systems, you probably understand explosions represent the worst-case scenario for everyone involved. This is why it’s so important for organizations with commercial electrical systems to do everything possible to prevent “arc flash incidents.”

Safety + Health Magazine describes what happens during an arc flash as “Electric current leaving its intended path and traveling to the ground, or from one conductor to another, through the air.” The result? The air temperature can reach 35,000 degrees Fahrenheit—three times hotter than the sun’s surface. Arc flashes also produce a loud noise comparable in decibels to a gunshot.

And all of this happens in less than a second.

As you may have guessed, arc flashes are extremely hazardous for people. They can also cause significant damage to expensive electrical equipment and operational downtime.

Want to avoid arc flashes?

Start with these three best practices for commercial electric systems.

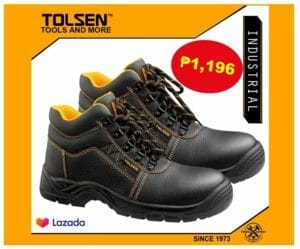

1. Wear Proper Personal Protective Equipment

The first line of defense against worker injury is personal protective equipment (PPE). Organizations must adhere to the latest version of the National Electric Code (NEC) released by the National Fire Protection Association (NFPA), which outlines the minimum levels of protection workers need — as predicated by the nature of the environment in which they work.

The NFPA 70, released in 2018, breaks down two major categories of PPE for workers:

- Everyday work clothing: Arc-rated long-sleeve shirt and arc-rated pants or arc-rated coveralls (minimum arc rating of 8); applicable for arc flash PPE categories 1 or 2.

- Arc flash suit: A total clothing system (minimum arc rating of 40); applicable for arc flash PPE categories 3 or 4.

Every organization is responsible for knowing these requirements and providing workers with compliant PPE, from head to toe.

2. Use Compliant Equipment

PPE is the first step toward safeguarding humans against the consequences of an arc flash, but it does nothing to prevent incidents. A major component of arc flash protection is the nature of the commercial electrical equipment an organization is using in the first place. The most basic consideration is ensuring systems comply with the most recent version of the NFPA NEC, including switchgear and circuit breakers, to name a few key components.

According to the energy management firm Schneider Electric, utilizing circuit breakers with adjustable trip settings—including “instantaneous tripping”—that have been “chosen with arc flash levels in mind” can help organizations mitigate the likelihood and impact of an arc flash event.

When evaluating your electrical equipment, you may need to replace certain components with newer models or retrofit your existing gear with modern improvements. Avoiding arc flash begins with the equipment. Doing whatever you can to prevent a malfunction will go a long way toward protecting employees and circumventing expensive failures.

Regular monitoring and maintenance of all electrical equipment are also fundamental to preventing explosions. An example would be thermography or looking for “hot spots” on sensors resulting from loose connections or other faults.

3. Display Clear Warning Labels

Organizations must conduct arc flash risk assessments to stay compliant with NFPA standards. Based on your findings, you can then make informed decisions to stay compliant with PPE and equipment maintenance. Displaying arc flash hazard warning labels on equipment is another NFPA requirement.

These three best practices just scratch the surface of what organizations can do to avoid dangerous arc flash in commercial and industrial systems.

What safeguards do you employ?

Please share them in the comments section below.