Reinforcing steel in the Philippines is typically used in tall buildings and strong bridges, but it’s also being used unexpectedly in the Philippines. This material is not just for construction—it’s also inspiring creativity and strength in communities throughout the islands. This article explores nine surprising uses of reinforcing steel in the Philippines beyond traditional building projects. It’s interesting to see how this simple metal contributes to disaster relief, sustainable farming, and even local fashion. Let’s learn more about these innovative uses and celebrate the resourcefulness of the Filipino people who are discovering new and exciting ways to use reinforcing steel daily.

Understanding the Versatility of Reinforcing Steel in the Philippines

Reinforcing steel is a vital component in the Philippines, with diverse applications that extend beyond traditional construction uses. Apart from its role in building bridges and high-rise structures, reinforcing steel is increasingly employed in ground stabilization projects, particularly in areas susceptible to landslides and erosion. This versatile material also supports sustainable development efforts in the country, as architects and engineers utilize recycled materials to create reinforced concrete, promoting structural integrity while minimizing environmental impact. These innovative applications demonstrate how reinforcing steel in the Philippines contributes to urban development and ecological sustainability.

What are the 4 Types of Steel Reinforcement?

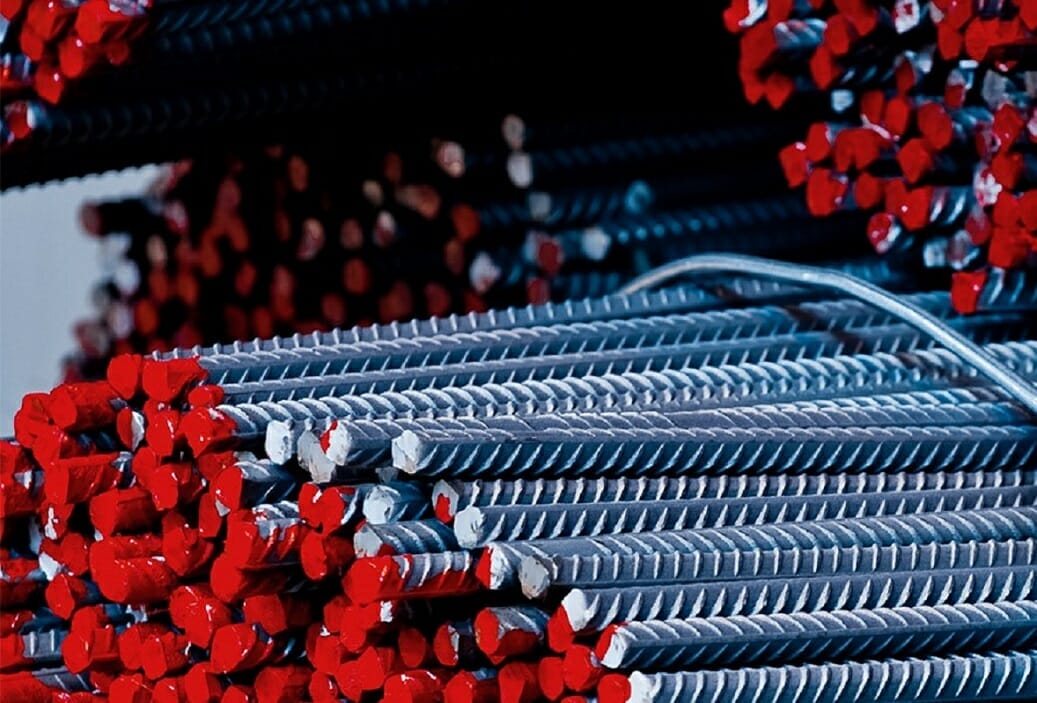

When considering reinforcing steel in the Philippines, it’s important to be familiar with the four primary types of steel reinforcement essential for construction professionals. Firstly, there are deformed bars (rebar), characterized by ridges or protrusions that significantly improve their bond with concrete. This makes them well-suited for tropical regions where heavy rains and moisture can potentially weaken structures over time. Secondly, plain bars have a smoother surface and are typically used in applications requiring less tensile strength or as support in lower-stress contexts.

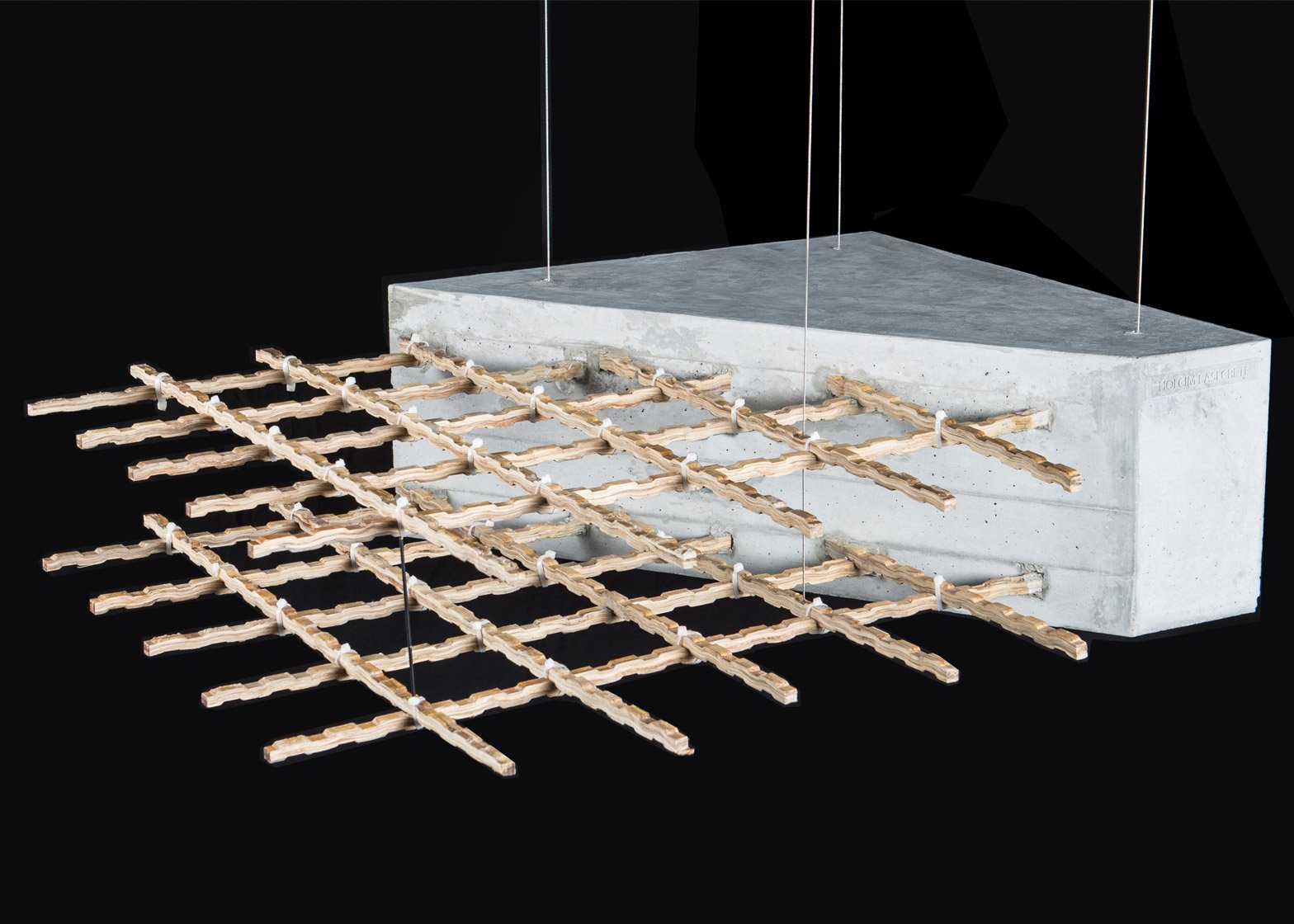

In addition, welded wire fabric is a crucial component, serving as a prefabricated matrix of steel wires arranged in a grid pattern. This simplifies installation and enhances structural integrity by evenly distributing loads across slabs and walls. Finally, the use of fiber-reinforced polymer reinforcement represents an innovative alternative that is steadily gaining popularity, particularly due to its corrosion resistance, making it particularly effective in coastal areas of the Philippines subject to high salt exposure. Collectively, each type addresses unique challenges encountered in volcanic landscape construction, ensuring that structures remain resilient against natural wear and tear.

What are the Properties of Steel Reinforcement?

When discussing the characteristics of reinforcing steel in the Philippines, it’s important to recognize its adaptability and strength. One of its primary qualities is its tensile strength, which enables it to bear heavy loads and substantial stress without yielding. This attribute makes reinforcing steel essential for many construction projects, from residential buildings to large infrastructure. Furthermore, its ductility allows it to deform under pressure without fracturing suddenly, providing crucial safety in earthquake-prone areas like many parts of the Philippines.

Moreover, reinforcing steel in the Philippines demonstrates remarkable corrosion resistance when properly treated, allowing structures to withstand harsh environmental conditions such as high humidity and salinity. This is especially critical for coastal regions where infrastructure is exposed to saltwater. Additionally, recent advancements have introduced various coatings and alloy compositions that further enhance these properties, resulting in more durable frameworks for our continually evolving urban environments. Understanding these characteristics underscores the importance of reinforcing steel in construction and paves the way for innovative practices and sustainability initiatives across various sectors in the Philippines’ growing architectural landscape.

1. Construction Industry Innovations in Urban Areas

The construction sector in urban areas is currently experiencing a wave of innovative advancements that use the unique properties of reinforcing steel in the Philippines. With cities constantly expanding and embracing modernization, engineers are utilizing advanced construction methods to improve structural integrity and address urban challenges such as limited space and sustainability. For example, using prefabricated components made from high-strength reinforcing steel in the Philippines allows for faster assembly times and reduces waste, leading to more efficient projects without compromising on quality.

Innovative applications such as fiber-reinforced polymer (FRP) bars are also emerging as sustainable alternatives to traditional steel reinforcement. These materials decrease the weight of structures and enhance corrosion resistance, which is crucial in the humid climate of many urban centers. Integration of smart technologies, such as sensors that monitor structural health over time, ensures safety and longevity with unparalleled precision. This combination of cutting-edge technology with durable materials signifies a significant shift in developing urban infrastructure in the Philippines, setting a benchmark for future constructions globally.

2. Infrastructure Development in Remote Regions

In the Philippines, developing infrastructure in remote areas is crucial for boosting economic growth and improving the quality of life for numerous communities. Reinforcing steel in the Philippines is a key material that plays a significant role in this transformation by enhancing the durability and resilience of structures built in challenging terrains. In regions susceptible to natural disasters like typhoons and earthquakes, reinforcing steel ensures that buildings can withstand extreme forces while adhering to safety standards.

Additionally, using locally sourced reinforcing steel supports regional economies and reduces transportation costs, thereby increasing construction efficiency. This localized approach encourages community involvement in infrastructure projects, empowering residents to contribute to the planning and execution stages. As a result, the emergence of ports, roads, and public facilities in underserved regions serves as symbols of progress and hope, offering improved access to education, healthcare, and job opportunities that were previously inaccessible to many residents.

Ultimately, reinforcing steel in the Philippines plays a crucial role in reshaping the socio-economic landscape in remote parts and demonstrates its diverse applications beyond traditional construction contexts.

3. Disaster Resilience in Earthquake-Prone Zones

In earthquake-prone areas, it is crucial to employ innovative construction techniques that harness the strength and flexibility of reinforcing steel in the Philippines to enhance disaster resilience. The strategic use of high-quality rebar improves structural stability and reduces damage during seismic events. Through the integration of advanced design principles, engineers can ensure that buildings can sway instead of collapsing under stress, fundamentally transforming how communities cope with natural disasters.

Additionally, local initiatives advocate for adopting modern reinforcement methods that incorporate cutting-edge materials alongside traditional rebar. This includes the incorporation of fiber-reinforced polymers or stainless-steel alternatives to improve longevity and resistance to corrosion—vital considerations given the region’s exposure to seismic activity and tropical climates. As policymakers collaborate with architects and civil engineers to enhance building codes, the thoughtful application of reinforcing steel in these environments emerges as a cornerstone for creating safer, more resilient urban landscapes throughout the Philippines.

4. Artistic Uses in Public Sculptures and Installations

In the Philippines, reinforcing steel has been creatively repurposed for artistic endeavors, moving beyond its traditional use in construction. Filipino artists are increasingly utilizing the strength and flexibility of rebar to craft visually appealing sculptures and installations that also carry deep cultural meaning. These pieces embody resilient community spirit and heritage narratives, transforming urban spaces into vibrant showcases where people can reflect and engage.

One notable example involves intricate latticework designs inspired by traditional weaving patterns from different regions, merging local artistry with the industrial nature of rebar. These installations not only add visual interest, especially when juxtaposed with lush greenery but also serve as symbols of the intersection between tradition and modern innovation. Positioned prominently in public parks and plazas, these rebar sculptures spark dialogues around sustainability and environmental consciousness, underscoring how reinforcing steel has transcended its utilitarian function to become a powerful symbol of artistic expression in the Philippines.

5. Eco-Friendly Projects Using Recycled Steel

Eco-friendly initiatives in the Philippines are driving sustainable construction practices, focusing on using recycled steel, particularly for reinforcing steel in the Philippines. Repurposing scrap steel from decommissioned buildings and industrial waste reduces environmental impact, minimizes resource consumption, and lowers carbon footprint. This approach has become a game-changer in urban areas, where green building initiatives integrate recycled reinforcing steel in the Philippines into projects such as eco-parks and community centers. Reinforced concrete made with recycled rebar enhances a building’s strength and showcases a commitment to ecological balance. This innovative approach promotes sustainability and resilience and supports local economies through job creation in recycling programs and sustainable construction practices.

6. Reinforcing Steel in Coastal Protection Systems

Reinforcing steel in the Philippines has become essential in constructing coastal protection systems due to frequent threats from typhoons and rising sea levels. This durable material enhances the structural integrity of sea walls, breakwaters, and revetments, making them resilient against harsh marine environments and providing crucial defense against erosion and flooding. Incorporating high-quality reinforcing steel significantly extends the lifespan of coastal infrastructure, ultimately safeguarding livelihoods in vulnerable regions.

Furthermore, the integration of local materials with reinforced steel not only enhances structural resilience but also promotes sustainable practices. Innovative design approaches allow for incorporating natural elements such as mangrove forests or coral reefs, combining traditional engineering with ecological conservation. The emphasis on reinforcing steel is pivotal in mitigating risks associated with climate change impacts while fostering a proactive approach to disaster risk management in many Filipino coastal areas. This integration of technology and nature underscores a broader commitment to protecting both people and their environments amidst growing challenges.

7. Applications in Agricultural Structures and Greenhouses

In agriculture, reinforcing steel in the Philippines plays a significant role beyond traditional construction. Specifically, in greenhouses, rebar provides crucial strength and stability to structures, ensuring they can withstand different climatic conditions and maintain optimal environmental control for crop yield. These structures often incorporate advanced designs that utilize engineered reinforcements, allowing farmers to maximize light exposure while ensuring durability against typhoons, a common challenge in the region.

Moreover, modern agricultural structures such as vertical farms and hydroponic systems increasingly rely on reinforcing steel for their frames and for integrated features like water channels that enhance irrigation efficiency. Producers can create sustainable environments that minimize resource waste and promote higher productivity by utilizing reinforced concrete elements. As the agricultural sector continues to innovate rapidly, understanding the unique applications of reinforcing steel in the Philippines becomes essential for stakeholders seeking to cultivate resilient and productive farming practices in the Philippines.

8. Advancements in Renewable Energy Projects

In recent years, there has been a significant increase in renewable energy projects in the Philippines. The pressing need for sustainable alternatives to traditional fossil fuels primarily fuels this growth. As the country invests in infrastructure developments such as solar farms and wind energy installations, the importance of using high-quality reinforcing steel, also known as rebar, cannot be overstated. Robust rebar provides structural integrity to these renewable energy facilities and enhances their durability against the extreme weather conditions typical of the region. This, in turn, ensures that the investments made in these projects are safeguarded for the long term.

Furthermore, advancements in rebar technology are playing a crucial role in optimizing these energy initiatives. For example, integrating high-strength reinforcing steel with improved corrosion resistance into solar panel mounts and wind turbine bases is proving to be a game-changer. This technological innovation is helping to reduce long-term maintenance costs while increasing the overall efficiency and lifespan of these renewable energy facilities. Ultimately, this supports the Philippines’ shift towards greater energy independence and aligns with global sustainability goals.

As more stakeholders engage in transformative projects, the critical role of reinforcing steel in the Philippines in establishing a resilient renewable energy framework in the Philippines becomes increasingly apparent.

9. Art and Design: Sculptural Installations

Sculptural installations in the Philippines are breaking the boundaries of traditional art by incorporating unconventional materials such as reinforcing steel. Artists are utilizing the strength and durability of rebar to create impressive large-scale sculptures, which serve aesthetic purposes and make impactful statements about resilience and sustainability in a rapidly evolving environment. These installations reflect modernity and cultural heritage, inviting viewers to contemplate the dual nature of steel—an essential material for infrastructure and a medium for creative expression.

One intriguing aspect of using reinforcing steel in the Philippines is its ability to symbolize strength amidst adversity, especially in regions prone to natural disasters. Sculptures inspired by local landscapes or historical events resonate with communities while showcasing the versatility of rebar beyond its conventional applications. This artistic approach encourages a discussion around urban development, environmental stewardship, and community identity, breathing new life into public spaces. As sculptors experiment with different forms and finishes, they highlight how industrial materials can be transformed into stunning works of art that inspire a connection between people and their surroundings.

10. Marine Applications: Coastal Protection Solutions

In the Philippines, there is a growing acknowledgment of the importance of reinforcing steel in coastal protection solutions. With the increasing threats posed by rising sea levels and frequent typhoons to coastal communities, innovative strategies involving rebar have become crucial elements in the construction of seawalls, breakwaters, and tidal barriers. These structures are not only capable of withstanding powerful wave forces but also contribute to stabilizing marine sediment, thereby protecting valuable coastal ecosystems.

By utilizing advanced engineering techniques that incorporate reinforcing steel in the Philippines, Filipino engineers can develop more resilient infrastructures tailored to specific local conditions. The versatility of different rebar types allows for the construction of lighter yet stronger structures, leading to significant cost reductions in ongoing maintenance and repairs. As our understanding of the marine applications for reinforced concrete systems advances, engineers in the Philippines are poised to lead the way in sustainable development that is in harmony with nature, ensuring the safety of communities and the integrity of the environment along vulnerable shorelines.

11. Agriculture: Strengthening Farming Structures

In the agricultural sector, it is crucial to prioritize the reinforcement of farming structures to improve productivity and resilience against natural challenges. The use of high-quality reinforcing steel in the Philippines is essential for constructing durable greenhouses, storage facilities, and irrigation systems that can withstand the region’s common typhoons and earthquakes. By integrating robust rebar into these agricultural infrastructures, farmers can create environments that support year-round cultivation and protect their investments.

Additionally, the use of reinforcing steel allows for innovative solutions such as vertical farming structures, which maximize land utilization in densely populated areas. With the increasing urban migration, many Filipino farmers are adopting multi-level planting techniques supported by strong rebar frameworks, enabling them to grow produce closer to market centers. This approach ensures a fresh supply of produce while minimizing transportation costs and carbon footprints, contributing to a more sustainable agricultural ecosystem across the islands. Reinforcing farm structures with steel elements is not just an investment in buildings; it is a reinforcement of food security for future generations.

12. Renewable Energy: Supporting Wind Turbines

Renewable energy has been rapidly advancing, with wind turbines emerging as a vital source of sustainable power generation. The Philippines’ diverse terrains and favorable wind conditions make it an ideal location for the construction of these impressive structures. However, such construction and maintenance require not only innovative engineering but also high-quality materials, particularly reinforcing steel. The robustness of these turbines relies on rebar to bolster their durability, enabling them to withstand extreme weather conditions such as typhoons, which are common in the region.

The strategic use of reinforcing steel in the Philippines plays a critical role in stabilizing the foundations that support these wind turbines against lateral forces induced by high winds. By utilizing locally sourced rebar, the construction of more resilient wind turbines becomes feasible. These turbines not only provide clean energy to communities but also stimulate local economies through job creation and skill development in manufacturing and infrastructure.

As more companies invest in renewable energy projects in the region, collaboration with dependable suppliers of reinforcing steel becomes imperative for maximizing efficiency and ensuring long-term performance. This convergence of sustainable energy advancements and material innovation demonstrates how technology can serve as a bridge between environmental objectives and economic growth in a country abundant with potential.

13. Earthquake Resilience: Enhancing Building Safety

In response to the Philippines’ frequent seismic activity, earthquake resilience has become a pivotal concern in the construction industry. The strategic incorporation of reinforcing steel in building designs has proven to significantly bolster structural integrity and safety during earthquakes. Reinforcing steel, also known as rebar, functions not only as support but as a crucial element for sustaining structures under stress, enabling buildings to endure lateral forces that would otherwise result in disastrous collapses.

Innovative approaches to reinforcing techniques are being developed throughout the archipelago. For example, the use of high-strength reinforcements in conjunction with advanced concrete formulations results in lighter yet more durable structures. This combination enhances earthquake resistance and contributes to overall sustainability by reducing material waste and energy consumption during manufacturing. As urban areas continue to expand in seismic-prone zones, the prioritization of these materials and methods ensures that Philippine cities are better equipped for future earthquakes, effectively transforming vulnerability into resilience, one rebar at a time.

Conclusion: The Future of Reinforcing Steel in the Philippines

In the foreseeable future, the role of reinforcing steel in the Philippines is expected to undergo transformation, driven by technological advancements and sustainable construction practices. The increasing demand for resilient infrastructure, particularly in the face of natural disasters, is placing emphasis on innovations such as high-strength and corrosion-resistant steel grades. These materials not only enhance durability but also contribute to the longevity of structures, resulting in long-term cost-effectiveness.

Additionally, there is a mounting need for environmentally friendly production methods in the manufacturing of reinforcing steel as sustainability becomes a focal point. The incorporation of recycled materials and lower-carbon processes has the potential to revolutionize the sourcing and utilization of rebar in construction projects. Embracing these changes will enable stakeholders in the construction industry to contribute to a more sustainable economy while ensuring the continued importance of reinforcing steel in building safe and resilient infrastructures across the archipelago. Therefore, comprehending these shifts will be vital for investors, builders, and policymakers seeking to harness the full potential of reinforcing steel in the Philippines.