The Advantages and Disadvantages of Valve Actuators

Basically, an actuator is a mechanism for closing and opening a valve. The main benefit is that you do not need someone to manually open and close it. In the manual mechanism, an attendant adjusts the valve using a geared or direct mechanism. There are power-operated actuators, hydraulic pressure, electricity actuators. Electric can be controlled remotely and there is a number of electric actuator manufacturer on the market.

They are very helpful for automatically regulating some level, flow or another process. Actuators for globe valves are the only way to close and open the valve. Moreover, there are other ways to remotely control the position of the valve.

Types

There are many types available such as diaphragm actuators, spring actuators, pneumatic piston actuators, hydraulic actuators, and Electric Actuators. We will discuss them one by one:

Pneumatic Piston Actuators

It works by converting the energy (Which is formed by compressing air) into mechanical motion. When it comes to the motion, it can be linear or rotary depending on the type. It contains a piston that helps in generating motive power. Basically, it keeps the air in the upper portion so that it can force the diaphragm to rotate the valve stem or move it.

Advantages: –

- Torque or High Force Capability

- Lightweight and compact design.

- It can work at high temperatures.

- High stiffness and Fast stroking speed

Disadvantages: –

- It requires additional spring and accessories for fail-safe

- Also, you need a positioner for throttling

- Need high pressure

- Very costly

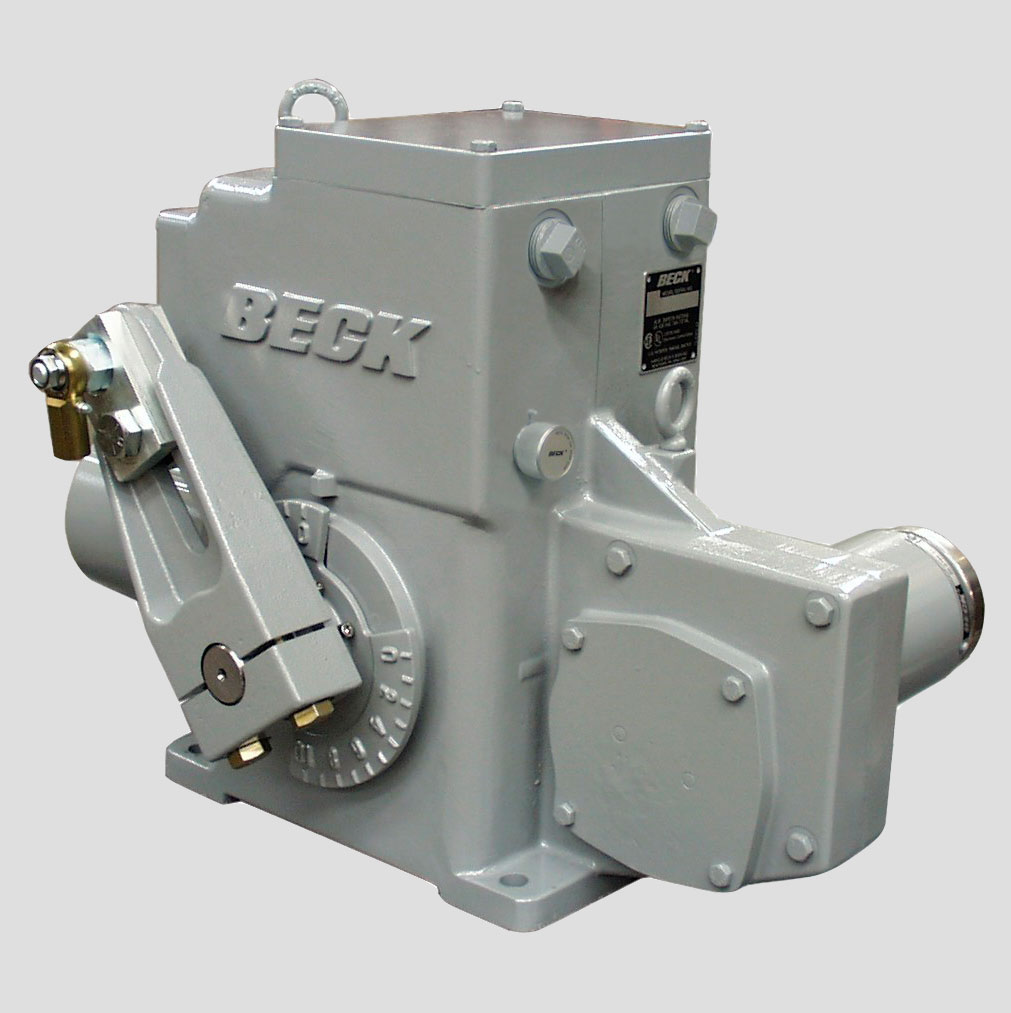

Electric Motor Actuators

In this type, a motor is used to convert electrical energy into mechanical torque. Electricity is needed to operate it.

Advantages: –

- Has a compact design and very high stiffness

- You do not need any piping to supply pressure.

- Moreover, it has a high output capability

Disadvantages: –

- The cost is very high and does not have fail-safe action

- Stroking speed is the slow and limited duty cycle

Electro-Hydraulic Actuators

This type works on the pascal law. It states that an increase in pressure in any part of a confined fluid causes an equal increase of pressure throughout the container. It means that if we apply a force in any part it will travel throughout the whole system.

Advantages: –

- High stiffness and output capability

- Great throttling ability and fast stroking speed

Disadvantages: –

- Costly

- Complex and difficult maintenance

- You need certain accessories to make it fail-safe

Spring and Diaphragm Actuators

The working of it is very simple. In this type, air to the diaphragm pushes the stem downward. Moreover, the air compresses the spring which in turn pushes the stem. Also, the air to the diaphragm casing causes the stem to move upward. It also compresses the spring, which in turn move the actuator stem downward.

Advantages: –

- The cost is very low

- Also, have the capability to throttle without positioner

- Fail-safe action

- Low-pressure supply requirement

- Can be easily adjustable according to the condition

- Maintenance is easy.

Disadvantages: –

- Size and weight are large

- Output capability is limited