The advent of the assembly line production system revolutionized industries across the globe. It quickly gained importance and has now become the basis of all industrial production systems worldwide.

However, the addition of robotic automation to this process began producing numbers earlier perceived to be impossible. Robots did not just improve the overall efficiency but also the production quality. Although robots can do almost anything in modern industries, their output mostly relies on how efficiently they are customized for a specific requirement.

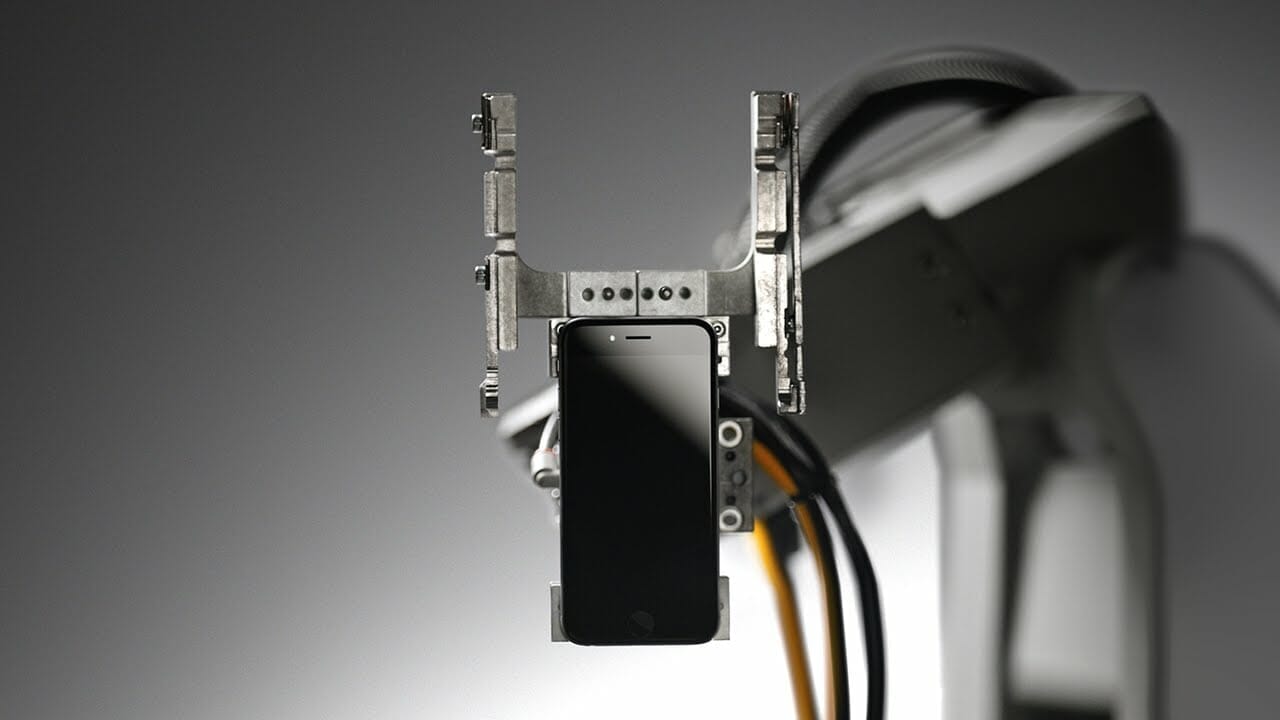

Sometimes referred to as End-of-arm-tooling (EOAT), these devices ensure the smooth functioning of assembly lines in modern industries. Read on to find out how robotic end effectors play a major role in automating assembly line tasks.

What are End Effectors?

Assembly robots must pick and align the components that go into the product. End effectors are tools fixed to the end of robotic arms that facilitate these actions. Without end effectors, the robots cannot perform the intended task and contribute to the assembly. Powering end effectors through electricity is the most common way to do it. However, based on their function, they can also be run on the magnetic force, hydraulics, or vacuum.

While there are dozens of types of end effectors, they can be categorized into three varieties based on whether they are utilized for the manufacturing process, verification system, or process automation.

The Role of End Effectors in Automating Assembly Line Tasks

An assembly line’s output depends on repetitively performing the same task on multiple units. Robotic automation delivers far better performance than manual assembly line production without compromising quality.

This is where robotic end effectors come to play – they enable the robotic arm to perform the intended action on the assembly line with precision. Primarily, three kinds of effectors are used for automating assembly lines:

Vacuum Heads

Vacuum head devices effectively find, lift, and move things with precision. These end effectors are used primarily for packaging-related activities ranging from packing small individual packets to larger cartons that need optimum space utilization. Depending on their size capacity, vacuum heads can pick up anything from small plastic parts to heavy pieces of metal.

A high-quality vacuum head device aids in high-speed packaging in trays, cartons, and case packers despite repeated format changes.

Grippers

Grippers, one of the most widely used robotic end effectors, are best for assembling, handling, and sorting materials. They pick and release parts at intended locations with remarkable accuracy.

Magnetic End Effectors

The only difference between grippers and magnetic end effectors is that these devices work with ferrous materials like sheet metal in automobile factories. They help handle and pack metallic containers, such as those in the paint and chemical industries.

Combo Devices

As the name suggests, combination end effectors deploy two more kinds of devices into one setup. Also called multi-grippers, these are customized to bring more functionality under a single design. Combination grippers can perform more complex tasks such as palletizing and bin-picking.

Make the Right Choice

Selecting the perfect end effector for your automation needs is equally important as the quality of the device. Unsuitable end effectors would not just slow down your assembly line process but also pose bigger threats.

Consider your assembly line requirements along with the type of supply available (for instance, fluid vs. electricity) before selecting the end effector. Multiple factors should be considered before making the decision; this is why consulting an experienced professional is often a good idea.

End effectors tend to pose challenges due to their consistent usage. Regular cleaning, greasing, and other maintenance activities can help you avoid these challenges and ensure the long life of your devices.