5 Things You Need To Know About Ethernet For Motion Control in Manufacturing Industry

When it comes to internet networks, it seems that the entire world has pretty much gone wireless. It’s easy to forget that there’s physical hardware behind all the connections many lives depend on. Many people today don’t even know about ethernet—something that was once critical for nearly every internet connection.

However, ethernet is still around. Not only that, but it also remains a prominent solution for several use cases. Motion control is one area where ethernet is still widely utilized. In fact, ethernet can be considered one of the most reliable types of connection in industries that rely on motion control.

What Are Ethernet And Motion Control?

In simple terms, ethernet is a technology made for connecting devices. It’s used in wide area networks (WAN) and local area networks (LAN). Unlike Wi-Fi which provides wireless connections, ethernet relies on cables and provides wired connections. It’s what often gives internet connectivity to a router, which then provides a Wi-Fi connection.

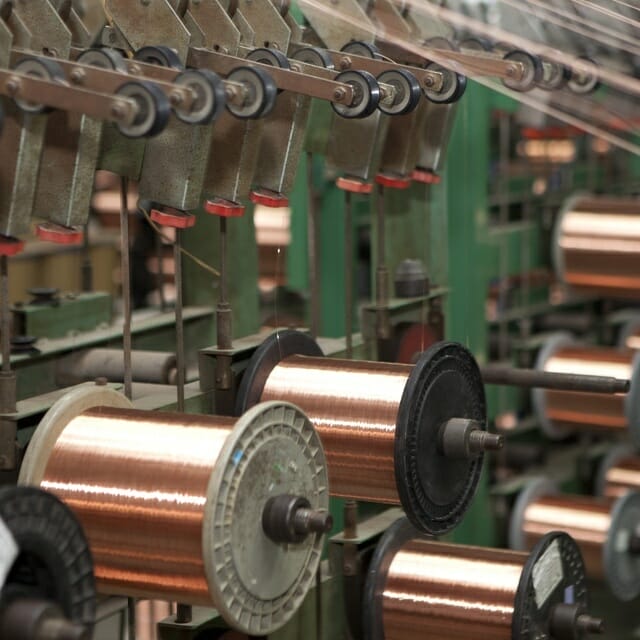

Motion control refers to systems consisting of individual components that all need to move in synch. You’ll see large motion control systems in industrial machining, manufacturing, and automation. Ethernet is a widely-used communication solution in fixed systems that don’t need to move around a space.

Here are five things to know about ethernet connections for motion control:

1. It Is Not Just A Cable

The word ‘ethernet’ doesn’t refer to the cable alone. Ethernet allows network devices to communicate via a protocol which is essentially a structured set of instructions for transferring data. Different network protocols are suited to different use cases. For example, EtherCat (Ethernet for Control Automation Technology) is widely known as one of the best protocols for industrial automation and motion control technology.

2. TCP And UDP In Ethernet

Most internet protocols use one of two main protocols as a ‘base layer.’ These are the Transmission Control Protocol (TCP) and the User Datagram Protocol (UDP). The main difference is that TCP is a connection-based protocol while UDP is a connectionless protocol.

TCP is generally more suited for systems where reliable, ordered data transfer is needed. On the other hand, UDP skips establishing a connection before data transfer occurs, thus making it faster at the cost of having a less reliable connection. However, UDP-based protocols are programmable to be just as reliable as TCP protocols.

The standard Ethernet/IP protocol uses TCP, but some ethernet protocols use UDP. The thing to note here is that these communication protocols use IP addresses to identify devices and set message destinations. This means that all devices in a motion control system would need an IP address to use the local ethernet network.

EtherCat, mentioned earlier, doesn’t use TCP or UDP, nor does it rely on IP addresses. This implementation essentially uses wired connections to identify different components and send messages. Messages are sent and ‘loop’ through each connected component.

3. The Industrial World Relies On It

The industrial world heavily uses automated machines in manufacturing and producing goods. These systems typically consist of several machines that use moving parts, but the machines themselves are typically set up and left in one spot.

Wired connections are a perfect solution for these machines. It’s easy to set up, and you’ll be able to know where each cable exactly leads. Additionally, ethernet ensures these connections are standardized to the system, fast, stable, and reliable. Therefore, motion control systems are crucial in industrial environments, and ethernet connections are like the lifeline of motion control systems.

4. Using Ethernet Is Often Cheaper

It’s not that wireless connections are unusable for industrial networks—they could be, but there are no real benefits to using Wi-Fi when the machines never move from their position. Ethernet is not only an optimal solution for many communication needs in machining, but it also happens to be relatively cost-effective.

Ethernet has more bandwidth than Wi-Fi, making it faster. In other words, achieving the desired network speed might cost more if you’re using Wi-Fi.

5. It Keeps Complexity Down

Installing and maintaining ethernet systems is generally easier than working with a Wi-Fi setup and network protocol. Wireless motion control needs more components, like a router, PC, and possibly receivers for each component. The router would probably rely on an ethernet cable anyway. Furthermore, Wi-Fi is more likely to fail, and most companies don’t have a specialist readily available to diagnose and troubleshoot problems as they occur.

Ethernet connections typically consist of a component and controller connected with an ethernet cable. Of course, these cables would extend to multiple components, but that’s about it. As you might guess, these are much easier to manage. Companies are also more likely to have staff members that already understand the setup well enough to fix any problems.

Conclusion

Ethernet is a staple for connecting individual components in industrial motion control networks. While wireless connections are great in other areas of life, they aren’t ideal for these motion control systems that need fast, reliable connections to ensure that all machines communicate efficiently. Ethernet is fast, affordable, stable, and offers excellent ease of use considering its applications. If you work with motion control, you understand how much it relies on data transfer, and ethernet will undoubtedly give you the best type of connection you’ll find.