NASA are holding a $2.5 million competition to build a 3D printed habitat for deep space exploration, including the agency’s journey to Mars. This pales in comparison with what Cazza, the Silicon Valley company behind innovative 3D printing systems, is trying to achieve here on earth: The world’s first 3D printed high rise.

“The plan is that within the next 5 years, we will produce a specialized 3D printer dedicated to this task and a range of smaller 3D printers and labor assistant robots to be able to work indoors, high-up in the skyscrapers. This enables us to make skyscrapers fully 3D printed,” Cazza CEO Chris Kelsey, told dmg events ahead of his participation at The Big 5 Excellence in Construction Summit.

“Currently, construction is standardized under a set of rules and despite the fact that structurally, 3D printing excels, there are regulations based on current methodologies which don’t apply to us, so we are working alongside governments to setting the standards for 3D printing as well.”

The first of these high rises could happen right here in the UAE, though that part is just a wild guess, but a good one and for a good reason.

We will find out why in a minute, but let’s first meet Kelsey, an accomplished entrepreneur who by age 17 had already built his first multi-million dollar company.

Along with Cazza co-founder and COO Fernando De Los Rios, the two have been building the business, printing, among other things, homes in just under a week.

This is what has caught the attention of UAE officials. Last year, Dubai’s Road and Transport Authority (RTA) invited Cazza to present company ideas and findings on the heel of the Emirate’s 2016 announcement of its 3D Printing Strategy, which aims to see 25% of buildings in the city printed by 2030.

Here’s your answer. The city is strewn with towers, and one would be inclined to deduce talks included 3D skyscraper printing.

Anything is possible

Cazza is participating at The Big 5 2017 show (26-29 November, Dubai World Trade Centre) and while the trip is masked with a veil of secrecy about naming future project plans, dmg events Middle East, Asia & Africa, the event’s organizers, uncovered several crucial insights.

“3D printing means a total disruption on how we build with concrete. We are no longer bound to straight shapes or formwork and methods that are labor intensive and represent safety risks for workers,” Kelsey begins.

In current practices, one needs to make special molds, custom build vents, glass, doors and interiors.

“You are going at least 10 times over the cost of a commonly shaped structure, but our technology makes “custom-making” cost competitive,” claims Kelsey.

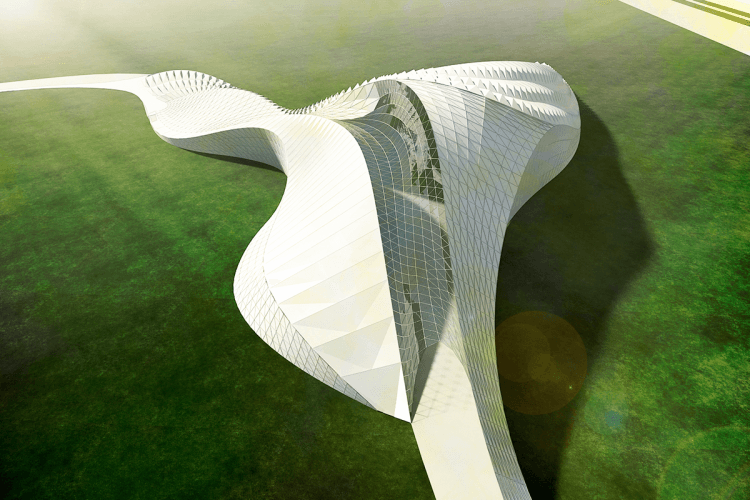

“We are able to design any shape that you can think of, and the freedom given by 3D printing with design, enables us to make stronger structures using less material.”

Optimized buildings

Cazza uses what it calls Topology Optimization. Kelsey explains that one can arrange the shape of a load bearing structure in such way that you have just the right amount of material in the sections that need it. “This reduces weight as you are only putting material in areas that will only bear loads.”

But as the technology starts to address building heights greater than today’s 6-8 meters low rise developments using 3D printing machines, will safety become an issue?

“There are always inherent risks associated with the construction industry, even with innovation, but with our technology, we are massively reducing safety risks by relocating those workers to other tasks when 3D printing, leading to fewer workers and less debris,” Kelsey explains.

360 degree 3D friendly

Fact is 3D gives design flexibility enabling structures to blend with the environment and surrounding ecosystem.

“We can easily create structures that take advantage of the local wind flow, provide natural cooling for the interior, save energy and reduce the carbon footprint of our buildings,” said Kelsey.

“At the moment all those features are essentially luxuries as associated labor and tooling required need customization, something that’s not an issue with 3D printing.”

Freeing building projects from cost and complex design strains leaves more room for safety, sustainability and cost efficiency, giving Cazza opportunities for a new focused approach to housing, while keeping the designs creative and appealing.

Construction industry reaction

Cazza plans to help facilitate UAE leaders’ vision to print 25% of all buildings in the UAE by 2030 and have 30% GCC companies using the company’s technology in construction within the next 5 years.

Are the big developers inclined to go that route?

Given that this technology has so many advantages to traditional construction methods, with savings on cost, material, time, and so on, you’d think the traditional construction industry is shaking in its steel lined boots.

“They are not afraid,” answers Kelsey.

“In fact, they have been actively looking forward for new technologies and integration, but those efforts have been focused mostly on material development. We are ground-breaking, as we’ve have taken our ideas to the next level and have gone beyond just material research.”

Kelsey added that the company has had advanced discussions with some of the biggest firms in Finland, UAE, GCC, and the US and found that the disruptive 3D technology is currently being internalized by developers in the construction industry.

“They love our ideas and products and are looking for ways on how to integrate them within their business models. This technology is new and is nothing they have seen before, so the process of adapting to it, takes time.”

Technology suppliers

Cazza says it has a couple of competitors worldwide, including Chinese based Win Sun and Amsterdam based DUS architects, that provide 3D printing services.

“However, we are the only company that is currently selling and able to deliver the technology to buyers. We are currently able to produce to a limited number of machines per production batch. This is increasing as we grow further and do expect costs to lower quite a bit with more supply and as the technology becomes commonplace,” announced Kelsey.

According to Cazza’s website an X1 3D printing robot can set you back $480k while an X1 Core is $620k, the choice being dependent on type of construction. Prices are a bargain if you consider that a typical construction crane could cost $1 million or more and carry a monthly fee of $15k for a 150-foot-tall one.

3D technology today can print just about anything it can map, and people best get used to the idea that printing buildings is here to stay and for good.

“All-in-all, what we hear most is that this is ‘cool’ and ‘the future forward’. While our technology is sophisticated, we don’t think it’s a bad thing that printing buildings doesn’t sound complicated. We aim to simplify and automate the build process, so that works for us,” said Kelsey.

To know more about The Big 5 visit www.thebig5.ae

For more information on the Excellence in Construction Summit, click HERE.