Ever wondered about phenolic boards and their importance in construction and design? Phenolic boards in the Philippines are made from layers of paper or fabric impregnated with resin and offer a range of benefits. However, like any material, they come with both pros and cons. In this article, we’ll explore the seven pros and cons of phenolic boards, shedding light on why they might be a great choice for your next construction project or why you might want to think twice. From their impressive moisture resistance to potential environmental concerns, understanding these factors can help you make an informed decision for your building endeavors. Come along as we delve into the fascinating world of phenolic boards and discover how they compare to other building materials available in the Philippine market!

Understanding Phenolic Boards in the Philippines

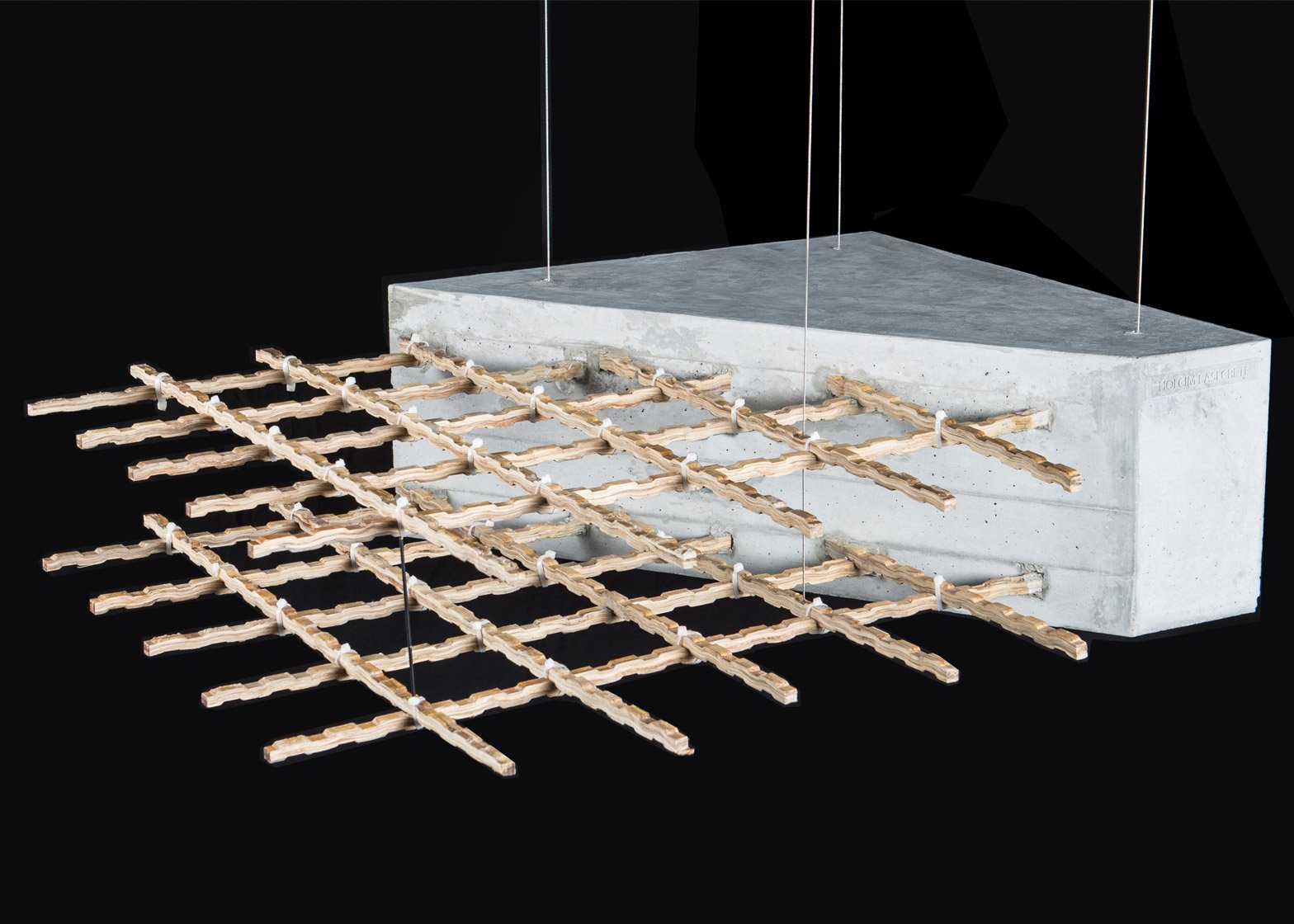

Phenolic boards are becoming more popular in the Philippines because they are strong and versatile. They are used for many different things, like construction and interior design. Phenolic boards are made by soaking layers of paper or fabric in a special kind of resin. This makes them tough and able to resist water, humidity, and changes in temperature, which is important in the Philippines, where the climate is hot and humid. They are also resistant to scratches and chemicals, so they stay looking nice even in places where lots of people go, like schools and shops.

Phenolic boards come in lots of different colors and finishes, so architects and designers can use them to create interesting and modern designs that also show the local culture. They are easy to cut and shape without losing their strength, so Filipino engineers can make all kinds of different designs and furniture with them. Many manufacturers are also working to improve the production process for the environment, so using phenolic boards is useful and good for the planet.

What Are the Applications of Phenolic Boards?

Phenolic boards are incredibly versatile and find applications across a wide range of industries thanks to their exceptional properties. They have gained prominence in the furniture manufacturing sector for their unparalleled durability and scratch resistance, making them the preferred choice for crafting high-quality office desks and workspaces that can endure heavy daily use. Moreover, the smooth and seamless surfaces of phenolic boards offer practical benefits and aesthetic appeal, enabling designers to create visually stunning pieces that seamlessly blend into modern and traditional environments.

In the construction industry, phenolic boards are increasingly sought after for wall panels and ceilings due to their exceptional moisture resistance and low maintenance requirements. They are particularly well-suited for environments with high humidity, such as hospitals and kitchens, where maintaining high standards of hygiene is crucial. In addition to their performance attributes, phenolic boards are often manufactured using recycled materials, appealing to environmentally conscious builders and consumers who prioritize sustainability while seeking durable and reliable structural solutions. This adaptability positions phenolic boards as a key component in innovative design solutions across various sectors.

Pros of Phenolic Boards

Here are the advantages of using phenolic boards in the Philippines:

1. Durability:

- They are highly resistant to impact, water, and chemicals, making them suitable for various applications.

Phenolic boards are distinguished by their exceptional durability, making them a highly sought-after choice for industrial and consumer applications. Their unparalleled resistance to impact sets them apart, enabling them to endure high levels of physical stress without succumbing to cracks or dents. This remarkable attribute makes them the perfect fit for environments characterized by heavy wear and tear, such as schools, hospitals, and factories in the Philippines. The long-lasting nature of these boards becomes invaluable in such high-traffic areas, reducing maintenance costs and ensuring a heightened safety level.

In addition to their outstanding physical resilience, phenolic boards boast impressive water and chemical resistance, making them essential in regions with high humidity and heavy rainfall, prevalent in many parts of the Philippines. Not only do they repel water, but they also exhibit resistance to a wide spectrum of chemicals, from harsh cleaning agents to acidic substances. This unique combination of qualities renders them perfectly suited for many applications, including use in laboratories and kitchens, where moisture and chemical exposure are prevalent.

The versatility of phenolic boards presents boundless opportunities across various sectors. Whether it’s the installation of durable partitions in public restrooms or the design of cabinetry in bustling commercial kitchens, these boards ensure that investments translate into enduring and unwavering results well into the future.

2. Moisture Resistance:

- Excellent performance in humid environments; does not swell or warp when exposed to moisture.

Phenolic boards boast exceptional moisture resistance, making them the top choice for a wide range of applications in the humid climates prevalent in the Philippines. In contrast to conventional wood or less durable materials, phenolic boards remain unaffected by moisture, as they do not swell or warp when exposed to humid conditions. This exceptional stability provides reassurance to builders and architects, ensuring that their projects will endure over time without being compromised by humidity-related damage.

What truly distinguishes phenolic boards is their unique composition, which involves combining resin-infused kraft paper with a resilient surface finish. This engineered structure enhances visual appeal and creates an impenetrable barrier against water. As a result, these boards maintain their structural integrity even in environments susceptible to dampness, such as bathrooms, kitchens, and outdoor facilities. For homeowners and business owners in the Philippines seeking durable and reliable materials, opting for moisture-resistant phenolic boards can significantly reduce long-term maintenance costs while improving overall indoor air quality by preventing the growth of mold and mildew.

3. Ease of Maintenance:

- Smooth surface that is easy to clean and maintain, reducing long-term upkeep costs.

The exceptional quality of phenolic boards is evident in their impeccably smooth, non-porous surface, a feature that greatly simplifies upkeep. Unlike conventional materials, which tend to trap dirt and moisture, phenolic surfaces repel stains and are less susceptible to fostering bacteria or mold. This characteristic ensures ease of cleaning and promotes a hygienic environment, particularly in places like schools, hospitals, and restaurants where cleanliness is of utmost importance.

Furthermore, the robustness of phenolic boards elevates their cost-effectiveness in the long run. Resistant to the rigors of daily use, whether it be scratches from furniture or spills from food, these materials maintain their pristine appearance longer than many other options. This longevity minimizes the need for frequent replacements and repairs, assuring proprietors of predictable maintenance expenses. Opting for phenolic boards is an aesthetically pleasing choice and a prudent financial investment for the future.

4. Thermal Stability:

- Retains its shape and structural integrity across a wide range of temperatures.

Phenolic boards are highly regarded for their exceptional thermal stability, demonstrating an impressive capacity to maintain their form and structural integrity across various temperatures. This characteristic is especially advantageous in the diverse climatic conditions of the Philippines, where dramatic fluctuations in humidity and temperature are commonplace. Unlike traditional materials that are susceptible to warping or degradation, phenolic boards exhibit remarkable resistance to these changes, ensuring that they remain dependable under varying conditions, whether it’s enduring scorching heat or heavy rainfall.

Furthermore, this resilience empowers architects and builders to employ phenolic boards in innovative ways within commercial and residential projects. By integrating these materials into designs where consistent performance is crucial, such as in exterior cladding or kitchen applications, developers can contribute to longevity without sacrificing aesthetics or functionality. The capability of phenolic boards to withstand extreme temperatures boosts durability and reduces maintenance expenses over time, establishing them as a prudent long-term investment for properties seeking to thrive in the face of climate change’s unpredictability.

5. Lightweight:

- It is easier to handle and install compared to heavier materials like plywood or concrete.

Phenolic boards offer a remarkable advantage with their lightweight nature, allowing for ease of handling and installation. Unlike traditional materials such as plywood or concrete, which can be difficult to manage and require additional manpower, phenolic boards provide a streamlined approach to construction and design projects. This reduces labor costs and promotes on-site safety by reducing strain on workers during material movement and positioning.

Furthermore, the reduced weight of phenolic boards facilitates creative applications, enabling designers and architects to explore larger panel sizes and intricate configurations without concerns about overwhelming structural supports. This opens the door to innovative designs that were previously constrained by heavier materials, ushering in a new era of modern aesthetics. Ultimately, choosing lightweight phenolic boards injects flexibility into project execution while upholding high durability and performance standards.

6. Versatility:

- It can be used in various applications, such as countertops, laboratory surfaces, and furniture.

Phenolic boards are highly versatile, making them an excellent choice for various applications. In residential settings, they can be used for stylish countertops and durable furniture, adding beauty and functionality to living spaces. Their unique combination of strength and lightness allows for innovative designs that may not be possible with traditional materials. For example, they can easily create custom kitchen islands and modern office desks.

In professional environments like laboratories or healthcare facilities, phenolic boards shine due to their high resistance to chemicals and moisture. They provide a safe and hygienic surface that can withstand thorough cleaning while maintaining their structural integrity over time. Additionally, their ease of fabrication enables architects and designers to create customized solutions suitable for any space, whether it’s a busy restaurant kitchen or a sleek medical workspace. This multifaceted nature enhances practical performance and offers opportunities for creative expression in material selection across diverse segments.

Cons of Phenolic Boards

Here are the disadvantages of using phenolic boards in the Philippines:

1. Cost:

- Generally more expensive than traditional materials like MDF or plywood.

The cost of phenolic boards can be a bit of a shock at first. They’re generally pricier than materials like MDF or plywood, which might make you hesitate. But take a second look. That price tag isn’t just a number; it’s an investment in long-term quality and strength. Sure, you might pay more upfront but think about the savings over time. Phenolic boards can mean less upkeep and a longer lifespan, turning that initial cost into a smart decision.

And it’s not just about the price. Phenolic boards have some impressive qualities. They can stand up to water and chemicals better than other materials, which makes them perfect for places that get a lot of traffic or are exposed to moisture. For businesses or projects needing reliability—like schools or healthcare facilities—the upfront cost becomes even more important when comparing short-term spending to future repairs or replacements. In the end, choosing phenolic boards means choosing quality that lasts, which often makes the higher price worth it in the long run.

2. Limited Aesthetic Options:

- It may have fewer design choices than decorative laminate finishes or solid wood.

Phenolic boards are highly durable and functional but offer fewer aesthetic options than traditional materials like decorative laminate finishes or solid wood. For design enthusiasts, a project’s visual appeal is just as important as its performance. While phenolic boards come in various colors and patterns, they often lack the intricate textures and warm tones that real wood or high-quality laminates provide.

This limitation may present challenges for those aiming to create inviting spaces with rich designs. However, architects and designers are increasingly finding innovative ways to overcome these constraints. By integrating phenolic boards with complementary accents, such as natural wood elements or vibrant graphics, they can create striking contrasts that enhance the overall space without compromising functionality. Embracing this innovative approach enables personal expression even within the limitations of phenolic materials.

3. Brittleness:

- While durable, they can be prone to chipping or cracking if subjected to high-impact forces.

Phenolic boards are known for their impressive durability, but their inherent brittleness can be a double-edged sword. While they are highly resistant to wear and tear in typical everyday use, exposure to high-impact forces can result in chipping or cracking. Picture these boards being used in bustling environments such as schools, commercial kitchens, or public bathrooms where rigorous activity is common. In such settings, these vibrant surfaces may easily succumb to unexpected knocks and bumps, leading to a gradual loss in visual appeal over time.

Interestingly, the brittleness of phenolic boards has prompted users to reconsider installation practices and implement protective measures. Precautionary steps such as strategic placement away from high-traffic areas or bumpers can significantly prolong the life of phenolic boards. Furthermore, some innovative designs incorporate reinforced edges that enhance resistance to impacts without compromising the aesthetic qualities that make them a popular choice for modern interiors.

Understanding these materials’ strengths and limitations is key to maximizing their benefits while minimizing potential drawbacks.

4. Specialized Tools Required:

- Installation may require specific tools for cutting and finishing edges properly.

When working with phenolic boards, having the right set of specialized tools at your disposal is incredibly important to achieve a truly professional finish. These high-density panels are not only simple to install, but their unique properties demand precision cutting and edge finishing to bring out their full potential. A quality circular saw equipped with a fine-toothed blade is absolutely essential for effortlessly slicing through the dense material without any chipping. At the same time, sleds can provide even more control during installation. Moreover, using router bits specifically designed for plastics can make all the difference in achieving smooth edges that prevent splintering and enhance the overall visual appeal.

In addition to the cutting tools, it’s paramount to pay close attention to detail when finishing the edges. Investing in sanders or orbital sanders guarantees that edges are meticulously smoothed out, resulting in a beautiful and polished look that can elevate any space—from retail environments to office settings. If you’re considering adding decorative accents or specific profiles, having specialized routers at hand grants you the ability to customize your project in a way that showcases both your craftsmanship and creativity. In essence, while phenolic boards offer durability and versatility, equipping yourself with these tailored tools elevates your project from ordinary to extraordinary, allowing you to realize your design vision to its fullest potential.

5. Not Eco-Friendly:

- Often made with synthetic resins that are not biodegradable and may have environmental concerns during production.

The environmental impact of phenolic boards is intrinsically linked to their reliance on synthetic resins, which are primarily derived from petroleum-based compounds. This raises concerns about their non-biodegradability and highlights potential harm during the manufacturing process. Producing phenolic boards can release volatile organic compounds (VOCs), contributing to air pollution and creating unhealthy work environments for factory workers. This oversight in sustainability practices poses a significant challenge as industries increasingly prioritize eco-friendliness.

Moreover, while phenolic boards are celebrated for their durability and resistance to moisture, this longevity comes at an ecological cost. Unlike natural wood products, which can decompose and return nutrients to the soil, synthetic alternatives persist in landfills far longer than anyone would prefer. As consumers become more environmentally conscious, the importance of selecting building materials that align with sustainable practices becomes crucial—not just for immediate use but also for the well-being of future generations. In a world striving toward greener solutions, acknowledging these drawbacks becomes essential in making informed choices about construction materials.

6. Thermal Conductivity:

- It can conduct heat poorly, which may affect usability in certain applications where temperature control is crucial.

The phenolic boards are known for their exceptional durability and versatility. However, their thermal conductivity can present challenges in applications where precise temperature control is crucial. Unlike metals or some composites, this material has a relatively low heat conduction capacity, which can be beneficial in insulation scenarios. Nevertheless, this characteristic can hinder performance in environments that require rapid heat dissipation or consistent thermal regulation, such as electronic housing or specialized architectural elements.

In various industries, from construction to manufacturing, the impact of thermal conductivity cannot be overlooked. For example, when used in building facades or machinery components exposed to fluctuating temperatures, poor heat conduction can result in overheating problems or even long-term structural inefficiencies. Consequently, while phenolic boards offer excellent resistance against environmental elements and mechanical stress, thoughtful consideration must be given to their placement and function—particularly in situations where effective heat management is crucial for safety and functionality.

Where to Buy Phenolic Boards in the Philippines?

Looking to buy phenolic boards in the Philippines? You’ve got some great options! If you like the convenience of online shopping, check out Lazada and Shopee. They offer various construction materials at competitive prices, and you can even read reviews from other buyers to help you decide. Keep an eye out for promotions and discounts to save even more! Local hardware stores are a great choice if you prefer shopping in person. You can get immediate assistance from the staff and inspect the boards yourself to make sure they meet your needs. Plus, you might get some helpful tips for installing and maintaining the boards in the Philippines. Happy shopping!

Recap: Weighing Your Options on Phenolic Boards for Construction in the Philippines

When considering construction materials in the Philippines, it’s important to weigh the pros and cons of phenolic boards carefully. These materials offer durability and resistance to moisture, which are crucial in a tropical climate. However, their initial cost is higher compared to traditional options. While the upfront investment is important, it’s also essential to think about long-term value. Choosing phenolic boards may lead to lower maintenance costs in the future, which can positively impact your budget.

Additionally, it’s crucial to consider the environmental impact of your choice. Phenolic boards have structural advantages and sustainability due to their long lifespan, but it’s important to source them from manufacturers that prioritize eco-friendly production methods. This enhances the longevity of your constructions and contributes positively to local ecological goals.

Ultimately, your decision to use phenolic boards or alternative materials will depend on how well they align with your project’s requirements and values. Balancing durability with budget constraints can lead to innovative construction practices that resonate with future generations.