SMB process automation can transform your business in many ways. There is an investment in such systems, but the benefits outweigh the costs. As such, engineering systems from the likes of Honeywell, Rexroth, and Allen Bradley are common, even in small companies.

The Cost of Manufacture

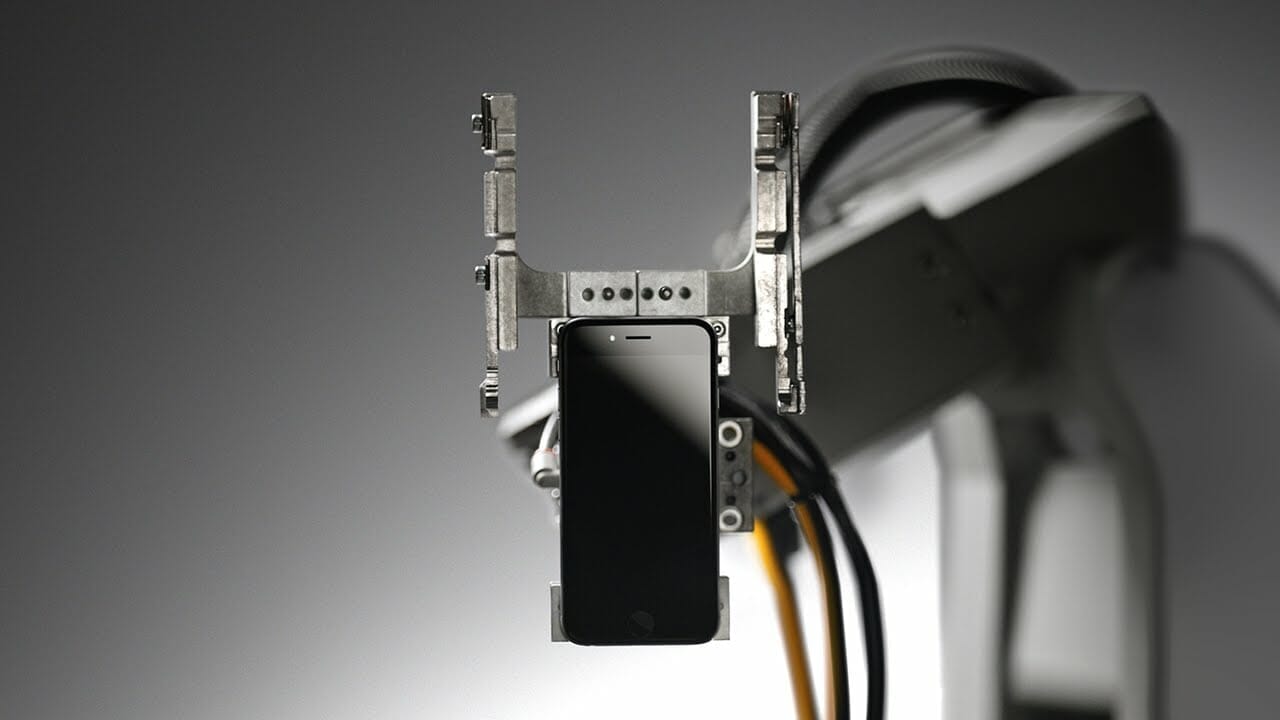

Manufacturing your own products comes with multiple benefits and major challenges. There are specific engineering systems that need to be in place. From cutting vinyl stickers to building cars, everything must be precise. Precision comes with costs, and there is always the issue of human error and even pay! Automated systems with pre-programmed patterns can operate on a 24-hour basis with monitoring and reduce the associated costs of traditional manufacturing.

Compliance Through SMB Process Automation

Your business might survive, and it might not. 20% of startups fail within the first couple of years. One of the main problems is they fail to meet compliance targets. Whether you install automated systems or not, these must be met and are challenging in some sectors. However, with automated processes, there is a much higher chance of meeting compliance targets once your system is configured correctly. Automation at an SMB might just get you past two years!

Production Rate Targets

Targets are a cornerstone of modern business. For manufacturing, these are essential. You will need specific targets when it comes to production rates in order for income to offset losses. Customers will not wait for you to catch up and will source their products elsewhere. Process automation will run, and the engineers who monitor it are capable of doing so. With a well-trained team, an automated system will help you meet targets and exceed what you need!

Dramatically Reduced Errors

There is no room for error in manufacturing. Every second costs money and downtime can be a disaster. An automated system with backup systems and reporting helps highlight and reduce errors. Any automated system worth investing in will have these features and help the business.

Veering from standard operating procedures

Process automation is programmed. It can only do what it is programmed to do. Therefore, there is minimal room for deviating from the procedure set forth in the manufacturing process.

Missed steps in a sequence

Every automation process has a set sequence. Barring a major bug in the system, a quality automated system will not miss steps or skip a sequence like a human can sometimes do!

Poor reporting and documentation

Whether it’s for compliance regulations or for backup purposes, a quality automated system will come with reporting and documentation that details every step, process, and interaction.

Human error is the most common cause of accidents, missed manufacturing steps and even cyber vulnerabilities in a modern business. Automated processes dramatically reduce the chances of any of these. However, you can recover systems due to reporting and recording.

Increased Customer Satisfaction

Customers want what they have paid for, and they want it in the time frame agreed upon. Common manufacturing mistakes and human error can delay entire shipments and cost you a lot of money. Process automated systems will produce what you need and when. And because the sequences take the same amount of time every time, you can give customers an exact date for when they can expect their products to be created and ready for delivery to their business.

SMB Process Automation Transparency

There are many compelling reasons for transparency these days. Even though most companies don’t operate this way, it can be an advantage for your business. 94% of customers prefer transparent brands. With an automated system, you can be as transparent as you want. From the entire manufacturing process to the materials used and even a record of every interaction, it’s all there. This also helps with audits and compliance, as the data is recorded for all to see!

Opportunities for Collaboration

Collaboration in business is shunned by most companies. But it can also be a powerful way to attract new customers. But how does automation help with this? Imagine you have a clothing brand that runs via an automated system. Partnering with another brand is as simple as changing the sequence for stitching, color and patterns. All the data you need can be uploaded or programmed into the system, making collabs much easier and successful without errors.

Summary

Manufacturing costs will come down with SMB process automation. Automation also dramatically reduced the chance of errors that are often made by humans. The ease of operational changes also opens up your brand for effortless collaboration within manufacturing.