3D printing is not necessarily a new technology, as it was introduced in 1983. Yet, it has developed rapidly in recent years. It is now more affordable for businesses and allows for making many processes faster, safer, and more sustainable. It includes hardware, software, and materials for production and hiring IT contractors to provide modeling and maintenance.

3D printing impacts many aspects of our lives, starting with construction and up to medicine. It allows for the production of many things and types of products. It can be a small simple prototype or a highly technical part of an airplane. Mostly, it is already altering the building and manufacturing industries.

3D printing is also vital for medical causes as it can create artificial human organs for transplantation. Such innovation can change the quality and longevity of people’s lives.

Therefore, more startups and companies integrate this technology into their work. They upgrade projects, buy hardware and software, and find IT contractors. This is understandable,, as 3D printing can combine production and construction with sustainable development.

3D Printing In Construction And Sustainable Development

The principles of sustainable development include a wide variety of aspects. It allows human evolution and development in all aspects of life and science while sustaining natural resources and ecosystems. The main idea is to create and maintain a better world for future generations with a maximal reduction of damage to the planet.

As for now, there are 17 goals of sustainable development, and 3D printing can help with several of them:

- Sustainable cities and communities. 3D printing allows the fast and effective construction of new housing, which can help solve the problem of affordable living for many people.

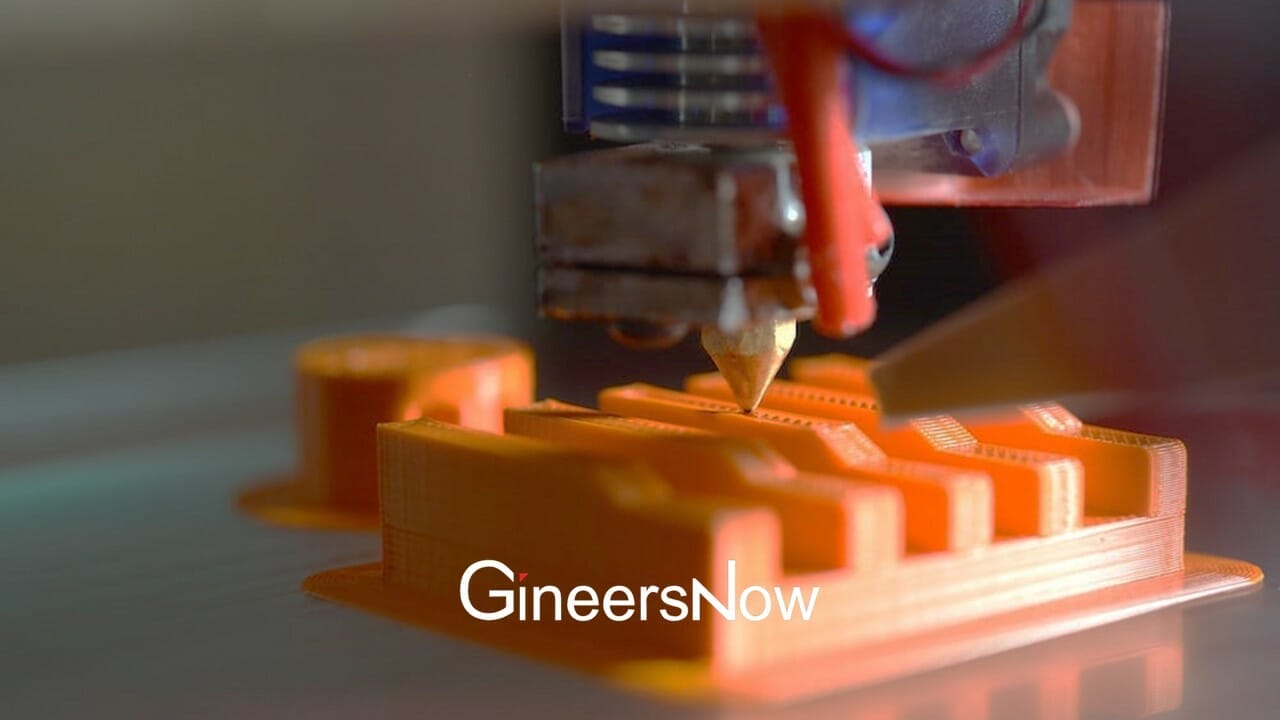

- Responsible consumption and production. This technology, or additive manufacturing, creates details by layering material according to the digital model. It is more sustainable than traditional construction, where the detail is cut out of the sheet of material. There is much less waste, and almost all materials are used for their purposes. It is also possible to recycle plastic into the material for a 3D printer, which reduces plastic pollution. It is logistically more efficient. There is no breakage during the transportation of details or materials, as they can be produced on the site. It also means less transportation in general and a decrease in transport-related pollution.

- Decent work and economic growth. The new technology provides new jobs, and there is a demand for professionals who can maintain them. A company needs to hire IT contractors to create projects and models that will be printed out. This way, additive manufacturing creates more employment options and better salaries for specialists.

- Climate action. There are many reasons why this new way of construction is eco-friendly. It reuses plastic, it produces minimum waste, and there is no manufacturing pollution that comes from traditional factories. It is a greener construction.

- Good health and well-being. The detail or product is created by layering, which reduces construction health risks. This innovation decreases the number of incidents when working with hard machinery on construction sites to a minimum.

By all means, additive manufacturing will change the world as we know it. It is a more sustainable option for building and producing high-technology details and products. It creates new positions and better salaries for IT contractors for hire and specialists involved in developing and maintaining this technology.

Businesses That Successfully Integrated It

As this industry is in development now, many startups appear every year. 3D modeling and innovations require top IT contractors and professionals to work on making them easier, faster, and more affordable. Here are several companies to look up to.

3Devo

This Dutch company released its device in 2017. It recycles everyday plastic waste into 3D-printed granules. The idea is to reuse all plastic at home without any additional efforts. The device is called SHR3D, and it can shred up to 5 kg of plastic per hour.

Desktop Metal

It is a startup focused on metal additive manufacturing. This technology is slower and more expensive than plastic printing. Yet, it is completely necessary for construction and provides more sustainable and durable details. The company has introduced a printer suitable for office use and larger machines for industrial manufacturing.

nTopology

This company offers a new solution when it comes to additive manufacturing software. It is necessary to make processes faster. They’ve introduced the Element platform, which has changed the means of 3D design and modeling. It uses LTCX format instead of the old-fashioned STL and provides lightweight and advanced manufacturing. After all, to create a great product, one should find IT contractors and provide them with the best work environment.

In Summary

Additive manufacturing has already altered the idea of construction and all related processes. It makes building faster, easier, and more eco-friendly. Most importantly, it meets the goals of sustainable development in many aspects. It reduces waste and pollution, allows recycling on-site, and provides better logistics and fewer health risks for workers.