Understanding the basics of bending angle bars can make a big difference for beginners in construction and metalworking in the Philippines. It allows you to turn a simple piece of metal into a strong support for buildings, bridges, or your own home projects. Whether you want to improve your work skills or handle DIY projects at home, mastering angle bar bending opens up many possibilities.

This article will cover five essential tips and techniques for newcomers. We will talk about choosing the right tools and understanding the bends you can make. The explanations and advice are easy to follow and tailored for beginners in the Philippines. You will soon feel confident bending angle bars like a pro. So, put on your safety gear, and let’s explore the fascinating world of metalworking!

What is Angle Bar Bending?

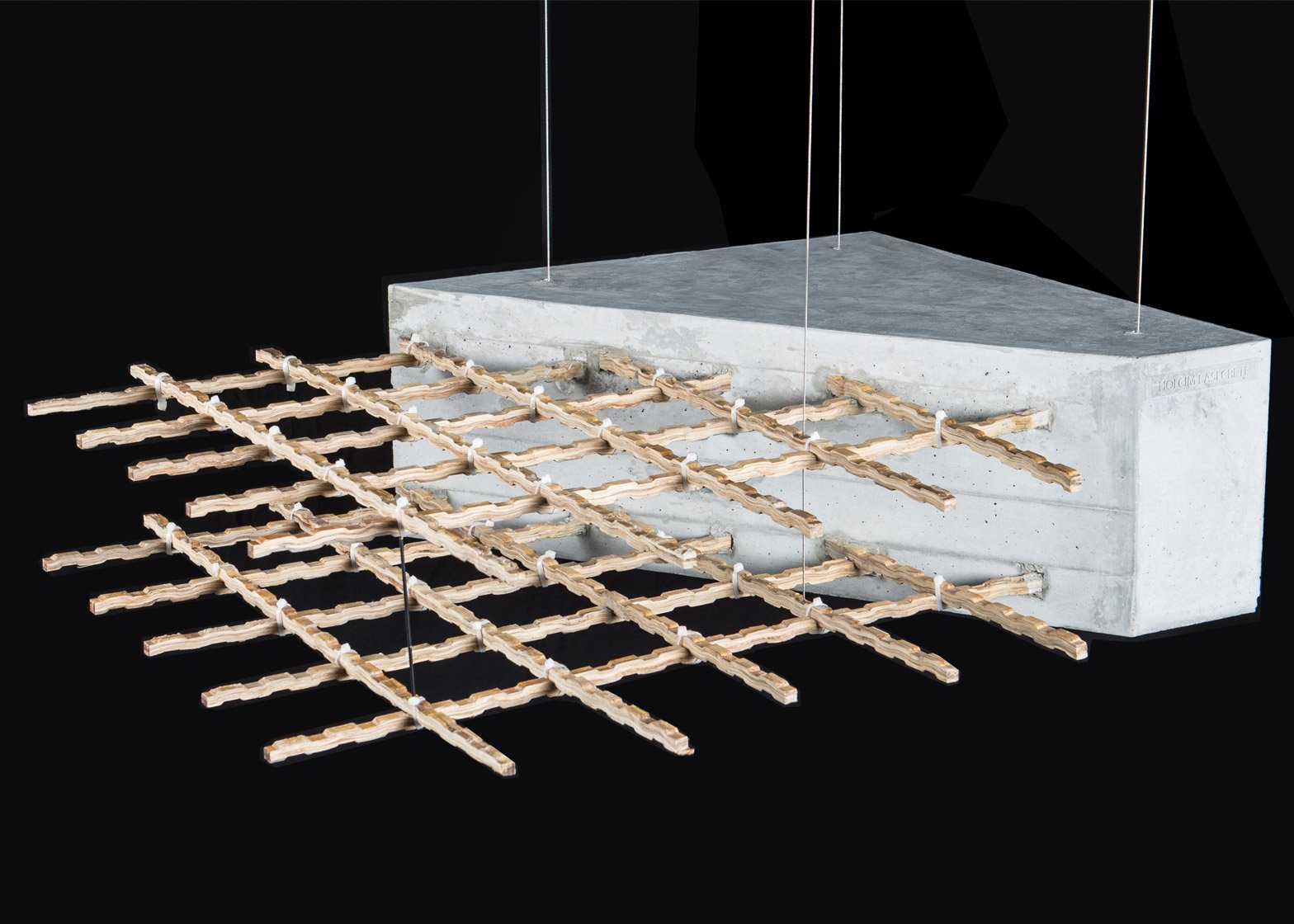

Understanding the art and science of angle bar bending is essential in metalworking in the Philippines. This intricate technique involves manipulating steel angles to achieve various configurations, serving crucial purposes in construction and manufacturing. Beyond the mere creation of visually appealing shapes, angle bar bending significantly enhances the structural integrity and functionality of diverse projects. For beginners, delving into the mechanics of this process can unveil a realm of creative possibilities, enabling precise material manipulation.

An integral consideration in angle bar bending is the selection of appropriate equipment. Ranging from manual hand benders to advanced hydraulic machines, each tool offers distinct levels of control and finesse. Novices are encouraged to acquaint themselves with these machines, as the choice of equipment can notably impact the quality and accuracy of the bends produced. Furthermore, a comprehensive understanding of material properties, such as yield strength, is imperative in effectively executing bending techniques. This knowledge empowers beginners to make informed decisions when tackling real-world applications, ensuring optimal outcomes.

Furthermore, mastering the art of angle bar bending not only enhances technical proficiency but also unlocks many creative opportunities in project design. Whether it involves the construction of frames or support structures, adept manipulation of angle bars enables builders to transcend conventional methods. Through innovative manipulation of angles and junctions, beginners can elevate basic designs into striking architectural features that not only stand out aesthetically but also guarantee structural stability. This skill set is both enriching and rewarding for individuals aspiring to excel in the field of metalworking.

Tools Needed for Angle Bar Bending

When it comes to bending angle bars in the Philippines, using the right tools is crucial for achieving precise and consistent results while ensuring safety. A key tool in your arsenal should be an adjustable bending machine, which allows you to create a variety of angles with accuracy. Coupled with high-quality jigs and fixtures, this equipment ensures smooth and secure metal bending. Additionally, investing in protective gear such as gloves and goggles is essential to prioritize safety during fabrication projects.

Furthermore, don’t underestimate the significance of accurate measurements. Utilizing measuring devices like calipers and protractors is essential for achieving precise specifications and maintaining structural integrity in your work. Finally, consider incorporating an angle grinder into your toolkit to achieve clean finishes after bending. This tool can effectively remove burrs and sharp edges, reducing potential safety hazards down the line. By equipping yourself with these essential tools, you’ll enhance your metalworking skills and be prepared to take on a wide range of projects with confidence and expertise.

Safety Precautions to Consider

When working with angle bar bending, prioritizing safety is paramount for the success of your projects. It is crucial to always wear the appropriate personal protective equipment (PPE) to ensure your safety. This includes wearing gloves to shield your hands from sharp edges and heavy-duty goggles to protect your eyes from metal shavings or sparks. Additionally, investing in sturdy steel-toe boots can help prevent foot injuries from dropped materials, as machinery can sometimes be unpredictable.

Understanding the workspace environment is equally important. Ensure that your bending area is clutter-free, as a tidy space minimizes risks and allows you to focus on your technique. Adequate ventilation is vital when working with metal, as fumes can be hazardous, particularly during welding or heating processes involved in angle bar manipulations. By integrating these safeguards into your project workflow, you’ll not only prioritize safety but also cultivate skill and confidence as you immerse yourself in the world of metalworking.

Types of Angle Bars Explained

Angle bars, which are predominantly constructed from steel, come in a variety of types that are specifically tailored for different construction and fabrication applications. One of the most common types is the equal angle bar in the Philippines, which is characterized by having two sides of equal length. This particular design provides versatility in structural frameworks, offering uniform strength and support across a wide range of angles. On the other hand, the unequal angle bar features two sides of different lengths, making it particularly well-suited for situations that require additional reinforcement on one side to accommodate heavier loads or unique architectural designs.

Another intriguing type is the perforated angle bar, which is specifically designed with pre-drilled holes along its length. This feature streamlines the attachment process and enhances flexibility during installation, making it beneficial for both temporary structures and permanent setups. Additionally, edge-treated angle bars introduce a layer of protection against corrosion while also ensuring improved aesthetic appeal. These are particularly valuable in regions with high humidity, such as the Philippines. Understanding these distinctions can empower beginners to select the right type based on mechanical needs, as well as considerations for longevity and aesthetics, ultimately adding value to their projects in diverse environments.

Measuring and Marking Techniques

Accurate measuring and marking techniques play a crucial role in achieving precise angle bar bending, particularly for individuals new to the process. Many Filipino beginners often fall into the trap of relying solely on standard measurements without considering the unique requirements of their specific project. It is essential for novices to invest time in understanding how to accurately read a tape measure, including fractions and millimeters, as this can significantly enhance the quality of their craftsmanship. Furthermore, incorporating tools such as calipers or digital scales into the process can provide a higher level of precision when determining the dimensions required for bends.

When it comes to marking, consistency is paramount. Utilizing high-quality marking tools, such as scribing pens or chalk lines, can ensure that your guide marks remain visible and durable throughout the entire bending process. Adhering to techniques like “measuring twice and cutting once” not only helps conserve materials but also instills confidence in your work. Integrating clear markings into your workflow enables you to visualize complex bends more effectively. This disciplined approach fosters an environment of learning and growth in metal fabrication skills.

5 Basic Angle Bar Bending Techniques for Beginners

Embracing these core techniques will empower Filipino craftsmen to transform raw angle bars into intricate structures, cultivating both skill and creativity in their craft.

Basic Technique 1: Manual Bending Method

The manual bending method is a traditional and time-tested technique that utilizes basic tools to achieve remarkable results in metalworking in the Philippines. By employing a sturdy bending jig or a dedicated bending tool, even beginners can effectively manipulate angle bars to create precise angles required for a wide range of applications. This method places a strong emphasis on skill and craftsmanship, enabling enthusiasts to form a deeper connection with the materials they are working with. Engaging in this hands-on process allows for the development of an intuitive understanding of metal properties and how they respond under pressure.

Furthermore, mastering manual bending not only fosters creativity but also enhances problem-solving abilities. Unlike automated machines that provide uniformity at scale, manual techniques offer the flexibility for customization in small-scale projects, making them perfect for artisans aiming to create unique pieces or modify existing structures. As one delves into practicing this fundamental method, it becomes evident how variations in force and direction can lead to different outcomes. Experimenting with these factors can transform basic bends into artistic expressions. Embracing the manual approach not only enhances practical skills but also deepens appreciation for the artistry involved in metalwork.

Basic Technique 2: Using a Hydraulic Press

Utilizing a hydraulic press for bending angle bars introduces a new level of precision and efficiency that surpasses traditional methods. This robust machine harnesses the power of hydraulics to enable the manipulation of metal into intricate shapes while ensuring uniform pressure distribution across the material. For beginners in the Philippines, mastering this technique can significantly reduce the learning curve, as a single incorrect bend has the potential to ruin a project. However, with a hydraulic press, clean edges and precise angles are consistently achievable.

An essential advantage of employing a hydraulic press is its adaptability. The machine’s settings can be easily adjusted to accommodate various thicknesses and materials without compromising strength or integrity. Furthermore, as one becomes more adept at this technique, the opportunity to experiment with custom dies tailored to specific design requirements emerges. This not only broadens creative options but also enhances craftsmanship. By integrating hydraulic pressing techniques into one’s skill set, productivity improves, and the capacity to produce professional-grade results that elevate projects from ordinary to exceptional is heightened.

Basic Technique 3: Heat Bending Technique

Heat bending is a versatile and innovative technique widely used by craftsmen, particularly in Filipino art and construction, to create intricate shapes and angles with angle bars. This method involves strategically applying heat to specific points on the metal, making it malleable enough to bend without compromising its structural integrity. What makes heat bending unique is its ability to produce smooth, seamless transitions between angles, allowing for the creation of design elements that are not only functional but also aesthetically pleasing.

When delving into the art of heat bending, precision, and control are of utmost importance. A steady hand and a good understanding of temperature thresholds will enable beginners to expand their creative horizons while minimizing material waste. Moreover, incorporating localized cooling techniques immediately after bending can help set the shape firmly in place, thereby enhancing stability for future projects.

As you delve deeper into this technique, consider experimenting with various temperatures. Each temperature will yield different results in flexibility and finish quality, offering unique opportunities for artistic expression within practical applications in the Philippine construction and industries.

Basic Technique 4: Roll Bending Process

Roll bending is a highly nuanced and captivating metalworking technique that seamlessly combines precision and creativity, making it an indispensable skill for those seeking mastery in the art of angle bar bending. This method involves delicately guiding the metal through a series of rollers, gradually coaxing it into the desired curve or arc. Roll bending’s benefit lies in its remarkable ability to yield smooth, uniform bends while maintaining the structural integrity of the material, a crucial consideration when working with robust metals commonly found in construction applications.

One of the most compelling aspects of roll bending is its versatility. Whether you are fabricating intricate architectural elements or tailoring custom support frames, this technique can accommodate a wide range of bend radii to suit your project specifications. For beginners, the efficiency of roll bending in mass production compared to traditional bending methods is particularly appealing. Furthermore, the opportunity to experiment with different roller configurations and settings provides a hands-on platform for deepening one’s understanding of metal behavior and refining craftsmanship skills.

Embracing roll bending as an innovative addition to your skill set opens the door to a world of design possibilities while ensuring structural reliability. This technique invites creativity and precision in equal measure, empowering Filipino practitioners to bring their metalworking visions to life with finesse and confidence.

Basic Technique 5: CNC Machine Bending

The utilization of CNC machine bending has revolutionized the way we approach the fabrication of angle bars in the Philippines. This cutting-edge technology offers a level of precision and efficiency that manual methods simply cannot match. By harnessing computer numerical control, the bending process becomes automated, allowing for the production of intricately designed components with exceptional accuracy. This is particularly beneficial for those new to the industry, as it leads to fewer errors and a more streamlined production process, both of which are crucial for maintaining quality and profitability.

What truly sets CNC bending apart is its capability to handle highly complex designs while minimizing material waste. Through the use of sophisticated software, practitioners can optimize bend sequences, ultimately achieving tighter tolerances and reducing scrap rates. Furthermore, CNC machines have the ability to store and replicate specific bending profiles, simplifying the process for individuals new to the industry and ensuring consistent results across multiple projects.

By embracing this advanced technology, craftsmen can elevate their work to new heights and prepare themselves for a competitive edge in an evolving market landscape. This prepares aspiring fabricators for success and ensures they are well-equipped to thrive in the industry.

Common Mistakes to Avoid

When bending angle bars, it’s crucial not to overlook the measurement and marking process. Skipping this step can result in inaccurate cuts, leading to material wastage and compromised structural integrity. It’s important to take the time to double-check measurements and marks to ensure precision. Remember, a well-measured piece today can save you from costly errors tomorrow.

Additionally, it’s common for Pinoy beginners to overlook the importance of proper equipment calibration. While it may be assumed that machinery and tools are set correctly out of the box, regular checks are essential for achieving accurate bends. Whether you’re using a manual bender or a hydraulic machine, ensure that everything is accurately calibrated according to specifications before starting your project.

Finally, safety gear cannot be underestimated. While it may seem tedious, protective eyewear and gloves are crucial for preventing accidents that could hinder your metalworking endeavors. Being proactive about safety is key to ensuring a safe and successful metalworking experience.

Maintenance Tips for Tools and Equipment

Taking good care of your tools and equipment is essential to ensure their longevity and peak performance, especially when undertaking projects involving angle bar bending. It’s important to clean your tools after each use to prevent the buildup of grime, which can impede their functionality over time. To tackle stubborn rust spots, you can create an effective eco-friendly cleaning solution by mixing vinegar and baking soda.

In addition to cleaning, it’s crucial to inspect your equipment regularly for signs of wear and tear. This proactive approach can save you time and money in the long run by preventing potential breakdowns or malfunctions.

Lubrication is another key aspect of tool maintenance. Many tools have moving parts that require regular oiling to ensure smooth operation. For angle benders in the Philippines, proper lubrication can significantly reduce friction and enhance precision in bending operations.

Organizing your tools is not just about tidiness; it also contributes to their longevity and efficiency. Keeping your tools well-organized means spending less time searching for the right tool and more time focusing on creating perfect bends.

Lastly, proper storage is essential for protecting your tools from unnecessary damage. Whether you store them in a toolbox or hang them up, establishing good storage habits is crucial for maintaining the overall excellence of your craftsmanship.

Endnote: Mastering Angle Bar Bending Basics

Mastering the basics of angle bar bending enhances your technical skills and opens doors to a world of creativity in metalworking. As you gain confidence, envision how angle bars can transcend their utilitarian origins, transforming into stunning architectural features or innovative furniture designs. Understanding the nuances of material properties and bending techniques allows you to experiment with different shapes and angles, offering endless possibilities for custom creations. Moreover, embracing this craft nurtures a mindset of problem-solving and precision—invaluable in workshops and everyday life. Each bend tells a story of meticulous planning and execution; every project becomes an opportunity to learn not just about metalwork but persistence, adaptation, and innovation. By honing these foundational skills in angle bar bending, you lay the groundwork for advanced techniques that will elevate your work to new heights, making each completed project a testament to your growth as a craftsman.