Steam boilers: What to choose and why?

Steam boilers are mechanical devices used to generate energy as steam. The entire process is quite explainable.

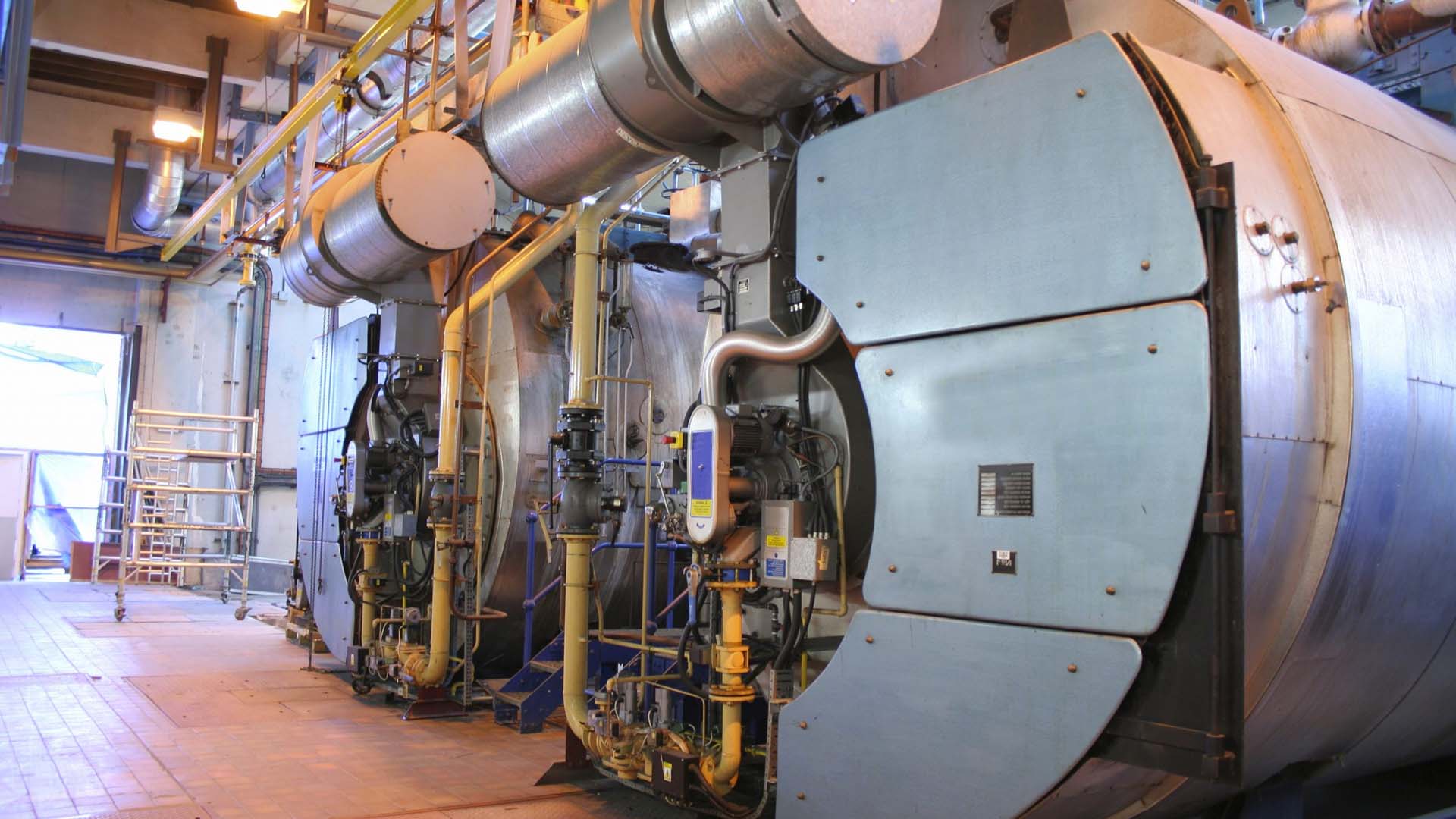

Steam boilers are pressurized vessels that transfer heat to water to produce steam. So how do steam boilers works? What is its application, and what are the types of steam boilers?

The article is all about answering logical answers to the question above.

How do steam boilers work?

Steam boiler works by transferring heat to water to produce steam. The water is heated at a suitable temperature under high pressure.

At first, the fuel is treated to a high temperature in a fiery furnace. Fuel might be natural gas, low-pressure propane or coal, etc. The furnace does its job by performing the combustion process.

The resulting gases from the combustion process then flow towards the water, gradually increasing the water temperature.

When the water is boiled up to the optimum temperature, then water is converted into high temperature and high pressurized steam.

The steam is then consumed for different activities, ranging from the industrial level to your HVAC system at home.

This whole process is performed inside a metal chamber of the boiler. To get a pure nack of the steam boilers, check product details.

The process mentioned above is the primary process used to make steam inside a boiler. However, the working of boilers might differ from type to type.

For example, fire-tube boilers operate in a different way than water-tube boilers. In fire-tube boilers, the metal tubes contain the fuel gases, and these tubes are surrounded by a vessel containing water. Steam is produced when the tube’s temperature escalates.

Contrary to this, water-tube boilers contain multiple tubes where water is present. Here steam is produced when the fuel gases outside the tubes get hot.

Let’s enlight some more light on these two most common steam boilers.

Fire-tube boilers

As the name indicates, fire-tube boilers operate by flowing hot gases through metal tubes. The vessel containing water around the lines gets hot up to the boiling temperature, generating steam.

Fire-tube boilers hold the ownership to be part of the first locomotive engine. These boilers are best used in small power plants as the rate of steam generation is lower than water-tube boilers. Fire-tube boilers don’t require high-level skills to work efficiently and economically.

Fire-tube boilers also take an edge over water tube boilers when there is a talk over the explosion.

They are less explosive than water tubes as the pressure is low compared to water tube boilers. The operating pressure for firetube boilers is approximately 25 bar.

A Fire-tube boiler is well known for generating steam. However, their enormous size and some inherent inefficiencies call for a much more advanced boiler to handle complex steam-producing tasks at the industrial level. And modern water tube boilers were introduced.

Water-tube boilers

Water-tube boilers are different as compared to fire-tube boilers. These closed vessels operate by the water flowing in the tubes, and the fuel gases surround the tubes. The gases are heated at a high temperature and pressure, which ultimately boils the water to generate steam.

Water-tube boilers are more capable of generating steam at a high rate than fire-tube boilers.

This makes them be the principal component of large industries and big power plants. Water-tube boilers are more advanced than fire-tube boilers, requiring much more concentrated attention to producing economic and efficient results.

Water-tube boilers can produce steam at a whopping pressure of over 125 bars!!. That’s five times that of the fire-boilers. However, it also put them at risk of explosion if not handled carefully.

Application of steam boilers

- Steam is used for agriculture. The agricultural tools are disinfected with the help of steam. Furthermore, it is also valuable for sterilizing the soil to get rid of the unwanted organisms in the soil.

- Steam is also used for cement production in large-scale industries. Moreover, steam boilers are needed in oil refineries and other massive power plants to carry out complex tasks.

- Steam also plays a crucial role in your HVAC systems to serve water heating, cooking purposes, and much more.

Conclusion

Steam boilers have evolved through different stages. They have become the emblem of starting the locomotive rail engines.

The dairy products ranging from foods, breweries, cement, and much more amenities are produced by steam.

Steam boilers manufacturers should focus on building top-quality steam generators with safety precautions.

And it’s the responsibility of the industry owners to always consider quality over quantity when buying steam boilers as a risk of explosion due to lack of knowledge is always there to haunt you. For further details, visit Yongxing China Boiler Manufacturer