CNC milling and turning are subtractive manufacturing processes that use computer numerical control to create objects from metal or plastic. However, some critical distinctions between the two processes can impact the type of object you can create. This article will look at those distinctions and help you decide which process is suitable for your project.

What is CNC milling, and what is CNC turning?

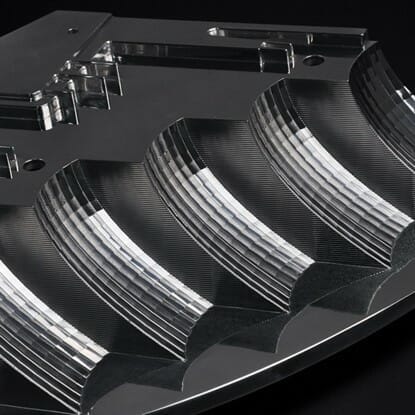

CNC milling is a subtractive manufacturing process that uses computer numerical control (CNC) to cut away material from a metal or plastic block to create an object. The CNC machine moves the cutting tool along two axes, making quick and precise cuts.

CNC turning is also a subtractive manufacturing process. Still, instead of using two axes to move the cutting tool, like in CNC milling, CNC turning uses one axis to rotate the material while the cutting tool remains stationary. It allows for sections of material to be cut evenly from larger objects like cylinders or discs.

The benefits of CNC milling over CNC turning

CNC milling is ideal for producing objects with complex geometries and can provide greater accuracy than CNC turning. With CNC milling, you have much control over the object’s shape since you can move the cutting tool along multiple axes. It allows intricate details to be cut into metal or plastic, which would not be possible with CNC turning.

However, one potential drawback of CNC milling is that it can create more material waste due to the need for multiple passes across a piece of material to achieve desired results.

The benefits of CNC turning over CNC milling

CNC turning is often preferred when producing large quantities of smaller parts because its single-axis motion can be faster and more consistent than CNC milling when cutting many identical objects.

Another benefit of CNC turning is that it is better suited for creating symmetrical parts since the material rotates around a single axis while being cut. It makes it easier to achieve precise cuts on both sides of the object.

A potential drawback of CNC turning is that it can’t produce objects with complex geometries as quickly as CNC milling can.

When to use each type of machining

CNC milling is often the preferred option for creating objects with intricate geometries because of its more significant control over their shape. CNC turning is ideal when producing large quantities of small and symmetrical parts since it can achieve consistency more quickly than CNC milling.

No matter which process you choose, you’ll find that computer numerical control machining offers many benefits to any manufacturing project. CNC milling and turning are subtractive processes that allow precise cuts in metal or plastic while creating minimal material waste. By understanding the distinction between these two processes, you can decide which one you should use on your next project.

For help choosing between CNC milling and turning for your project, consult a professional machining company. They will advise you on which process is best suited for your needs. With the proper guidance and expertise, you can ensure that your manufacturing project will go as smoothly as possible.

Examples of projects that would benefit from each type of machining

CNC milling is often used for projects requiring intricate geometries and fine details, such as medical devices or automotive components. It can also create housing and structural components for computers, electronics, and other machines.

CNC turning is often preferred for producing large quantities of small objects with symmetrical shapes like pins, rods, screws, and gears. It can also cut threads into metal parts or produce cylindrical shapes like tubes and pipes. In addition, CNC turning can quickly and accurately create shapes with cylindrical symmetry, like discs, dowels, washers, bushings, couplings, and shafts.

Conclusion

Understanding the distinction between CNC milling and turning is essential to choose the best process for your project. While both processes are subtractive machining techniques that offer precise results with minimal material waste, they each have unique advantages and disadvantages. With the help of an experienced machining company, you can decide which is best suited for your needs and get the most out of your metal or plastic components.

By considering all of these factors, you can ensure that you’re getting the most out of your machining projects while ensuring that every part is produced with precision and accuracy. Ultimately, CNC milling and turning are potent tools that can be used in various applications to create objects with precision and minimal material waste. Take the time to understand the differences between these two processes, and you’ll have all the information you need to decide which one is best for your project. Ultimately, CNC milling and turning provide precise results when used in the right circumstances. With this knowledge, you can ensure that your manufacturing projects are completed accurately and efficiently.