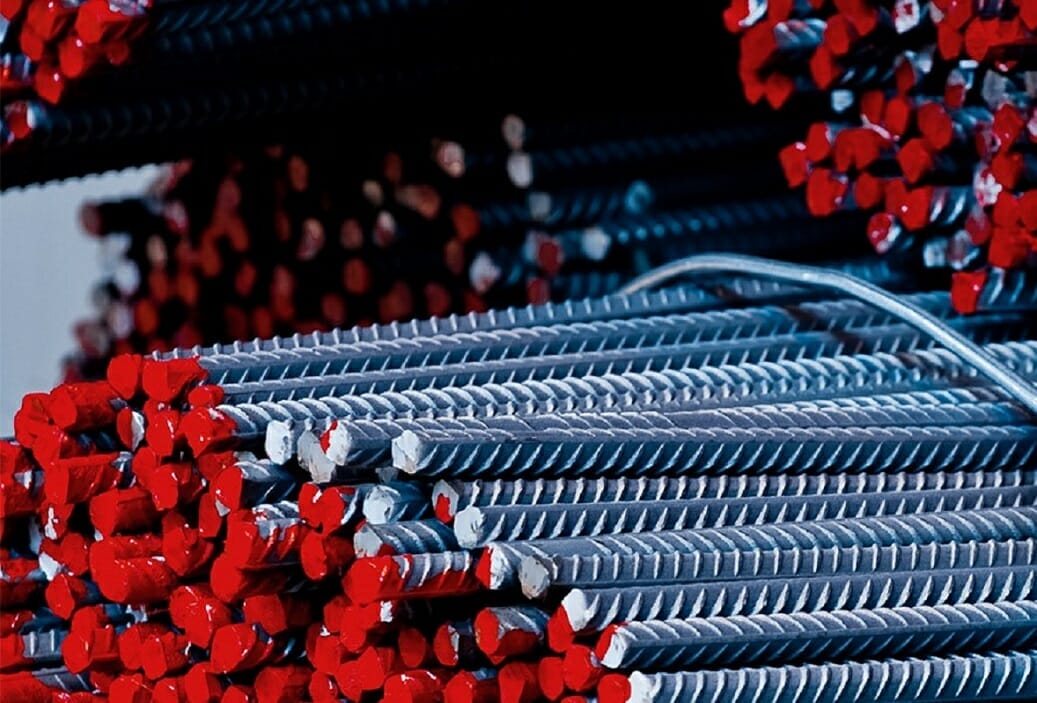

Did you know that steel bars are crucial to the construction and infrastructure projects in the Philippines? Many people are curious about how much steel bars will cost in 2025. Understanding this can help everyone plan their budgets better and keep an eye on the broader economic trends that affect different industries. Global market fluctuations and local demand have made steel bar prices unpredictable in recent years. In this article, we’ll explore the factors that influence the cost of steel bars in the Philippines, from international supply chain issues to government policies that encourage local production. Join us as we dive into this important topic and give you all the info you need to understand the changing costs of steel in our country.

Overview of the Cost of Steel Bars in the Philippines

The increasing cost of steel bars in the Philippines is a critical issue for both stakeholders in the construction industry and ordinary consumers. An array of factors, including the volatile nature of international market prices, shifts in local raw material supply, and the influence of government policies, directly impact the pricing of steel bars. Recent patterns indicate a consistent rise in prices, primarily driven by the heightened demand resulting from ongoing infrastructure projects and urban development initiatives nationwide. As industry players navigate this intricate landscape, a deeper understanding of the intricacies of pricing is essential for making well-informed decisions.

Furthermore, the cost of steel bars varies significantly across different regions of the Philippines. In Cebu, the cost of steel bars ranges from PHP 43.6 per kg to PHP 45.4 per kg. Major urban centers such as Metro Manila often grapple with higher prices due to increased transportation costs and heightened competition among suppliers. The cost is around PHP 337.95 for 10.5 meters to 4,383.51 depending on the grades and diameter. Conversely, in remote areas, prices might be relatively more stable but slightly elevated due to persistent logistics challenges. Collaborating with local suppliers can provide valuable insights into competitive pricing models that accurately mirror current market dynamics, while also fostering relationships that may lead to potential bulk discounts or favorable terms for large-scale projects.

Current Price Trends in Steel Market

In the latter part of 2023, the cost of steel bars in the Philippines has been markedly impacted by intricate global supply chain intricacies and variations in demand. The recent market upturn can be attributed to the surge in infrastructure projects and government efforts aimed at reinvigorating economic prosperity. This increased demand has prompted local producers to adapt their pricing strategies in response to rising raw material and transportation costs.

Furthermore, external factors such as geopolitical tensions and trade policies are exerting a significant influence on the trajectory of these price dynamics. Disruptions in key steel-producing nations have reverberated across Southeast Asia, causing ripple effects that are challenging construction firms in the Philippines to reevaluate their financial plans and project schedules.

Therefore, closely monitoring international market shifts can furnish valuable insights for businesses seeking to optimize their material acquisition strategies in the midst of fluctuating steel prices.

Factors Influencing Steel Prices This Year

The cost of steel bars in the Philippines has been influenced by various factors this year. One major driver is the persistent global supply chain disruptions caused by ongoing geopolitical tensions and climate-related issues affecting transportation networks. These disruptions have led to bottlenecks, resulting in increased shipping costs and delays, ultimately impacting local market prices.

Moreover, the increasing energy costs have played a significant role in shaping steel prices. As energy expenses rise globally, the production costs for steel manufacturers also increase, leading to higher consumer prices for steel bars in the Philippines. Additionally, the surge in infrastructure development projects across Southeast Asia has driven a spike in demand for quality steel bars, further elevating prices as suppliers strive to meet the heightened need while dealing with their own constraints.

Amidst this complex scenario, economic policies aimed at promoting local manufacturing present challenges and opportunities for consumers and businesses. Fluctuating tariffs and evolving trade agreements necessitate stakeholders to stay well-informed about how these dynamics will impact not only pricing but also overall availability and quality standards in the rapidly changing market environment.

Comparison with Previous Year’s Prices

When examining the cost of steel bars in the Philippines, it’s essential to compare this year’s prices with those from the previous year. The cost of steel bars in the Philippines has experienced significant fluctuations over the past year due to a confluence of factors. These include disruptions in the global supply chain, escalating raw material costs, and a surge in demand for construction projects. This rise in prices has not only affected businesses but has also sparked apprehensions about affordability, particularly for smaller contractors and DIY enthusiasts.

Notably, compared to the more stable pricing trend observed last year, current data indicates a sharp increase in costs. Industry analysts have reported price hikes of up to 10-15%, underscoring the heightened competition for limited resources in the post-pandemic economic recovery. However, there is a bright side to this situation: some regions in the Philippines may experience varying pricing due to local suppliers adapting more swiftly to shifts in demand dynamics. These disparities present opportunities for astute builders to explore cost-effective sources without compromising on quality, enabling them to craft better investment strategies in the midst of a constantly evolving market landscape.

Regional Variations in Pricing Across Philippines

The cost of steel bars in the Philippines exhibits significant regional variations, impacted by local demand, infrastructure developments, and transportation costs. In bustling urban hubs such as Metro Manila, the rapid surge in construction projects and heightened demand can lead to a significant spike in prices compared to more rural provinces. Conversely, areas with lower construction activity often enjoy lower prices due to reduced demand and decreased logistical expenses associated with the shorter transportation of materials.

Furthermore, external factors such as disruptions in the supply chain or fluctuations in international steel prices can further exacerbate these regional discrepancies. For example, islands like Mindanao may face higher costs due to limited access to suppliers and increased shipping rates. Additionally, the impact of local economies should not be underestimated; provinces that are actively investing in their infrastructure will likely witness an upward trend in pricing as a reflection of their growth aspirations. Having a comprehensive understanding of these intricacies enables builders and investors to make well-informed decisions regarding the timing and location of sourcing steel bars across the archipelago.

Impact of Global Events on Local Costs

Global events often ripple through local economies in unexpected ways, significantly influencing the cost of steel bars in the Philippines. Supply chain disruptions driven by international trade conflicts or natural disasters in other countries can result in shortages, causing steel bar prices in the Philippines to rise. This is exemplified if a major foreign supplier faces production halts due to geopolitical tensions, leading to increased costs and delays for Philippine construction projects as they vie for limited resources.

Additionally, macroeconomic factors like inflation rates and currency fluctuations significantly impact local costs. As the Philippines relies on imported construction materials and faces global increases in shipping fees, the prices on the ground are directly affected. In the face of a growing population and escalating infrastructure demand, comprehending these dynamics is crucial for stakeholders, such as developers and consumers. Understanding the interconnectedness of our world can empower decision-makers to adapt strategies that mitigate risk and control costs amid unforeseen global challenges.

Future Projections for Steel Bar Prices

As we look ahead in 2024 and beyond, the cost of steel bars in the Philippines is expected to be influenced by a combination of global market trends and local economic factors. Factors influencing the steel bar market include the continued increase in raw material costs, changes in demand driven by infrastructure developments, and potential regulatory modifications that could affect production.

As the government’s efforts to expand public infrastructure persist, local steel manufacturers may face the challenge of balancing heightened production expenses with competitive pricing strategies.

Additionally, uncertainties in international trade relationships may further complicate the forecasting of steel bar prices. Elevated trade barriers or the imposition of substantial tariffs on imported materials could potentially lead to localized shortages, thereby triggering a sharp increase in prices. Conversely, improvements in supply chain efficiencies or the adoption of alternative materials within the construction industry may lead to diverging trends and mitigate price rises.

Both investors and construction professionals should remain vigilant about these market dynamics as they navigate the changing landscape of steel bar procurement in the Philippines.

Practical Tips for Buyers and Contractors

When navigating the fluctuating cost of steel bars in the Philippines, buyers should prioritize timely research and trend analysis. It is important to stay connected with local suppliers to gain up-to-date information about changes in prices and the availability of steel. In addition, utilizing online platforms that track steel prices can be a valuable resource for planning project budgets. Buyers should also explore the option of purchasing materials in bulk or establishing partnerships with contractors to secure more favorable pricing.

For contractors, having a comprehensive understanding of the various factors that impact steel prices, such as global demand, shipping expenses, and local production capabilities, is crucial for accurately estimating project costs. Introducing flexibility into project timelines allows for strategic procurement when steel prices are lower, ultimately leading to improved profitability. Keeping material cost assessments regularly updated throughout different project stages promotes transparency with clients and nurtures strong contractor-buyer relationships.

By implementing these strategies, buyers and contractors can make well-informed decisions that adhere to budgetary limitations while delivering high-quality project outcomes.

Alternatives to Steel Bars in Construction

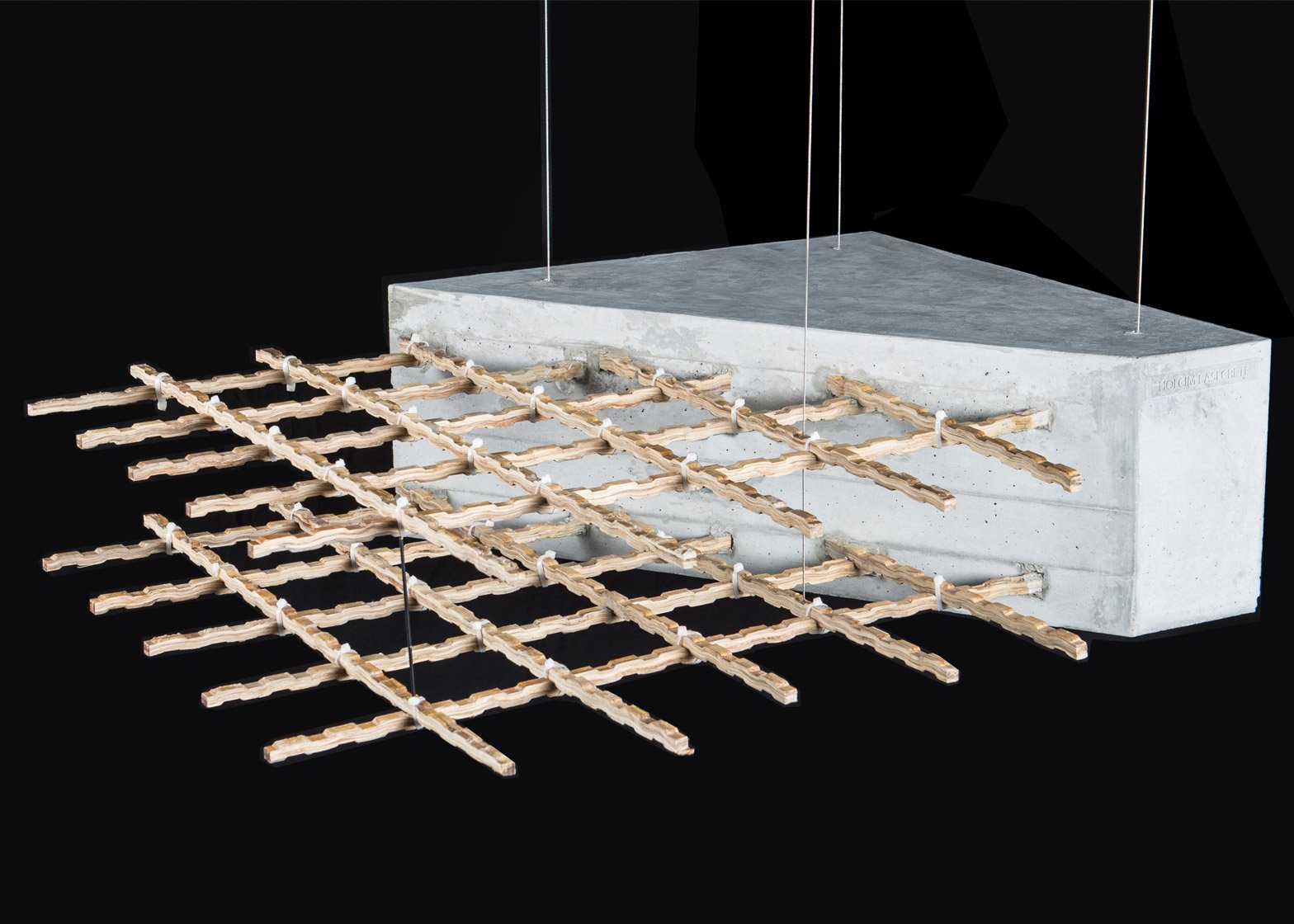

As construction costs continue to rise, the cost of steel bars in the Philippines has become increasingly scrutinized. The current situation has led builders and architects to seek out new solutions that can deliver both structural reliability and cost-effectiveness. One of the materials gaining popularity is fiber-reinforced polymers (FRP) due to their lightweight properties and resistance to corrosion. Unlike traditional steel, FRP does not require rust protection, leading to significant reductions in long-term maintenance expenses.

Another promising option is bamboo, especially in the context of eco-friendly construction practices. Responsibly sourced bamboo provides an economical choice while minimizing its environmental footprint. With its tensile strength comparable to that of mild steel, bamboo can be used in various structural applications if properly treated and engineered. Embracing these innovative materials not only allows builders to tackle the challenges posed by rising costs but also contributes to a more sustainable construction industry in the Philippines. Exploring these alternatives has the potential to redefine conventional project budgets without compromising safety or stability.

Conclusion: Summary and Key Takeaways

It’s really important to understand the cost of steel bars in the Philippines, especially if you’re involved in construction and infrastructure development. A bunch of things, like how much people want steel, the global prices of steel, and how steel gets to where it’s needed, all work together to decide how much steel costs. Differences in different parts of the country can also change how much things cost, so it’s important to know about that when planning projects.

The main things to remember are to get materials at the right time to avoid paying more later and to think about using different materials or new ways of building that might save money without sacrificing quality. By keeping up with what’s going on in the market and finding the best places to get materials, builders can make the most of their money and help the construction industry grow in a way that’s good for everyone. These tips aren’t just about saving money; they also help projects run smoothly in a competitive place like the construction industry in the Philippines.