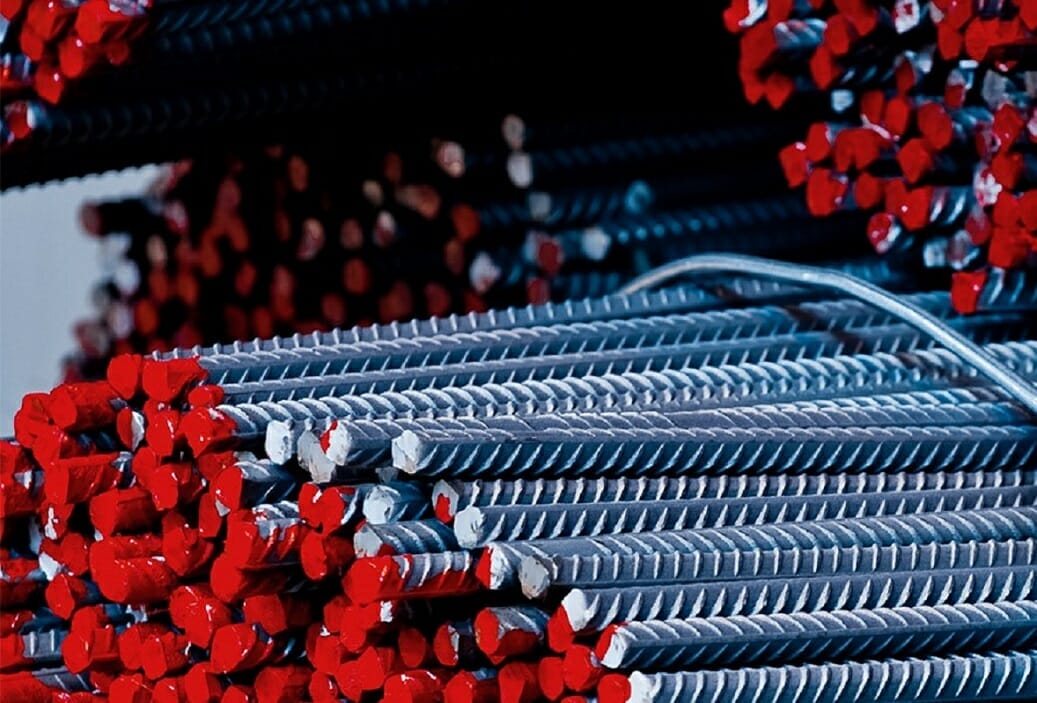

If you’re in an industry that requires the use of steel foundational equipment, you must know what the different kinds of hollow steel bars are.

Hollow steel bars are completely threaded. They’re known as “disposable” drill rods, and they’re used to drill a special kind of hole. With these drill rods, you can advance the drill string to your desired depth and then grout the drill string in place.

Using a hollow steel bar allows you to reinforce a portion of an anchor or pile with steel. Steel bars are known for their durability, strength, and weldability. One downside is that they lack the corrosion resistance needed for some specific projects.

In addition, hollow steel bars can be utilized as tie-down anchors, soil nails, micro piles, and many other challenging uses. With all of these different uses, hollow steel bars are a valuable tool for geotechnical contractors.

Types Of Drill Bits

When using a hollow steel bar, several different kinds of drill bits are available.

The first kind of drill bit is known as a versatile cross-cut bit. Aptly named, this drill bit can be used on a wide variety of projects. This type of drill bit is best used in carbide or hardened steel.

If you’re drilling into intact rock, consider using a button bit instead. While this drill bit also works for hardened steel, it excels best with intact rock.

Lastly, use a stepped clay bit for drilling into cohesive soils.

Which drill bit you use highly depends on the kind of material that you’re drilling through. In combination with the hollow steel bar, the drill bit you pick for your project is also determined by the borehole diameter. With a larger diameter of the borehole, you’ll have a higher load-carrying capacity, and you’ll also have greater grout cover.

If you’re unsure what grout cover is, it protects the anchor rod from corroding. This is an extremely important part of the process, as your structures will not hold if your anchor rods corrode too much. It is important to note that not every diameter bit will produce a parallel amount of a grout column. It is dependent upon the soil type. A 3-inch diameter bit can produce a 6.5 to 9-inch grout column, depending on the soil type you’re working with.

Hollow Bar Corrosion Protection

Before using hollow steel bars, research how long it will take for the bar to corrode. Corrosion protection can depend on how aggressive the environment is where the steel bar is being placed and on the installation methods.