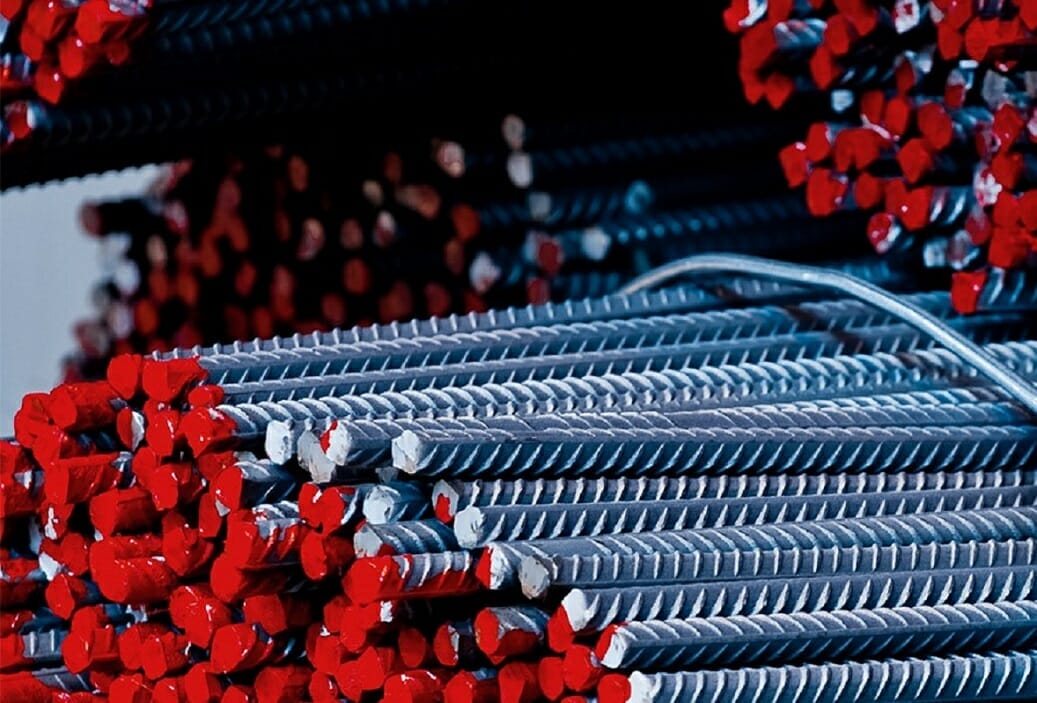

Steel has become an integral component in the construction of most buildings, which is why steel frame construction has had an increasing market share within the civil construction and engineering sector. But is steel the only ideal material, or are there any better alternatives? To answer this question, we will examine the merits and drawbacks of structural steel frame construction in comparison to other construction options.

Understanding Steel Frame Construction

Some of the notable structures that were prominently built using steel frames included warehouses, garages, and massive agricultural buildings. However, the traditional uses of steel frame construction have transcended to other applications, such as building commercial skyscrapers, factories, and residential dwellings. The material is an excellent option for different construction projects for several reasons that include:

- It is durable; thus the building will have a long-term structural integrity

- It is affordable, making it a readily available construction material.

- It is sustainable, therefore, minimal construction costs.

One of the amazing pros of using steel in construction is that the structural components can be fabricated off-site and transported to where needed. It will lower the required labor while also minimizing the impact of factors, such as adverse weather conditions, that may delay the completion of the project.

From the fabrication point of view of the steel frame construction, you will have to contend with some pros and cons that are as follows:

Advantages Of Steel Frame Construction

The benefits are based on a comparison between steel frame construction and concrete, wooden, and brick constructions. Get your quote for a quality steel building from Murray steel buildings

- Strength & Durability

Steel components are lighter and sturdier than weight-bearing concrete and wooden products. For instance, the standard weight-bearing wooden fabrication is nearly 30%- 50% heavier than the steel equivalent. As such, steel will make for a stronger and more durable component.

- Easy Fabrication In Different Sizes

The fabricated products can be made in an array of designs and sizes to suit different applications. That means that customization is possible so the components can bear a specified load.

- Fire Resistance

Steel can be engineered to have exceptional heat-resistances; thus, the steel frame construction products can help retard the spread of fires as well as reduce the risk of such a crisis. The material can also have an added special flame-retardant that enhances its resistance to fire.

- Pest & Insect Resistant

With the steel frame, you will not have to worry about destructive invaders such as burrowing insects and animals, as is the case with most timber structures.

- Moisture & Weather Resistance

The material can be engineered to have outstanding moisture resistance depending on its carbon content. Moreover, they can be treated with extra powder and hot zinc coating to enhance the resistance to corrosion and face the effects of moisture and water, especially for the steel components of the structure that will be exposed to the weather.

Disadvantages of Steel Frame Construction

Some of the commonly cited drawbacks of steel frame construction include:

Thermal Conductivity

The high efficiency in conduction heat is also a downside to the use of steel because it means that the material will not be efficient in preserving warmth. As such, the insulation value of walls will be less, by nearly 50%, due to heat transference away from the walls. The result is reduced energy retention for the building. Given this, insulation measures are necessary when using steel frame construction to counteract the material’s thermal conductivity.

Reduced Flexibility On-Site

It is possible to adjust wooden components on-site. They can be cut to size, drilled, and hammered with nails to screw them together to strengthen the joints. In the case of steel, the measurements should be precise to minimize waste and on-site labor. That is why most of the steel fabrications are made off-site. However, there is a risk of the final product being inaccurate, which means that the entire component will not fit, thus holding up the project process. Avoiding such a thing by working with a company such as GLW is possible. We ensure that we observe accuracy in all aspects of fabricating steel frame components by taking a consultative approach, thus guaranteeing everything is confirmed before production.

Supporting Structures

The steel frame constructions cannot work independently; they will require additional components such as sheathing, insulation, drywall, and some concrete or wooden elements that will all work together to become a solid building. Based on this fact, the construction time is long, and the processes outweigh the advantages of having the steel fabrications made off-site.

Steel Frame Constructions For Your Project?

If you have a construction development project and need help figuring out whether steel frame construction is a good fit for it, contact us today to learn more. Our engineers will walk you through the various fabrication options and help you understand how structural steel components can increase the strength of your building while cutting the construction time and costs.