Exploring the Technology Behind Electric Vehicle Batteries

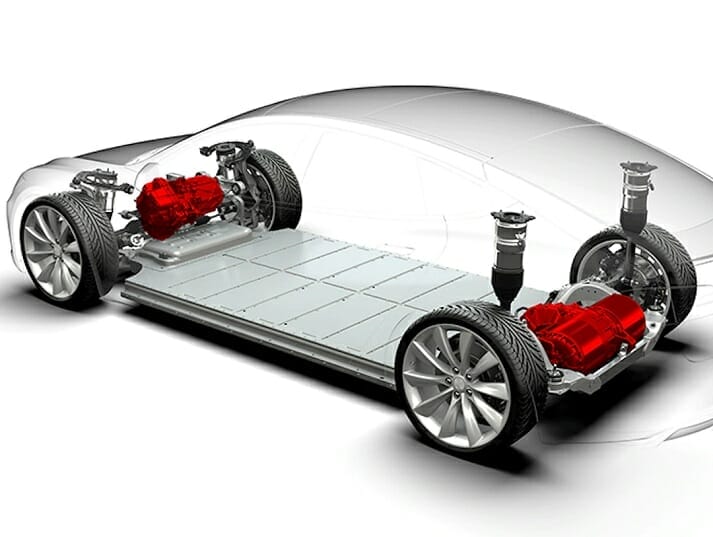

The electric vehicle (EV) market has grown tremendously in recent years. As a result, many manufacturers are developing batteries to improve the range of their EVs. One of the essential parts of these batteries is the anode material.

With electric vehicles (EVs) being the future of transportation, it’s important for companies to start investing in research and development. Here’s an in-depth look at the technologies behind electric vehicle batteries and why this is such an exciting time for EVs.

What is the problem with Current Technology?

Automakers are establishing massive factories to produce lithium-ion batteries, which are currently used in the majority of electric vehicles. Tesla is planning giant factories called Gigafactory in Texas, Nevada, and other states. Ford is expanding its manufacturing operations in Tennessee and Kentucky. In Tennessee and Ohio, General Motors is constructing battery factories. The list could go on and on.

However, companies are facing difficulties in collecting nickel and cobalt, which are essential to manufacturing EV batteries. The geological barrier is the main reason behind this collection. As a result, the industry is seeking to develop next-generation battery technology that is both cheaper and faster to charge. And the best part is there will be no more shortage of raw materials.

Rapid prototyping services offered by many companies are playing a big role in this development.

The sales growth of Electric Cars

Electric Vehicle sales in the United States accounted for just approximately 4% of total sales in 2021, which was a significant increase.

Since the world is changing, vehicle manufacturers are gearing themselves for an electric future. According to our current EV trend study, EV investments increased by 41% between 2020 and 2021 and will exceed $330 billion between 2021 and 2025.

Between 2020 and 2025, GM and Volkswagen intend to invest $35 billion and $42 billion, respectively, in electrified and driverless vehicles. Jaguar and Volvo intend to market only electrified automobiles by 2025 and 2030. By 2035, GM aims to sell solely electrified passenger vehicles.

High Voltage Development for EV Batteries

Electric Vehicle batteries have come a long way in just a few years. From providing a few hours of range at best to now being able to provide weeks, even months of range, the potential for batteries to improve the range of electric vehicles has been huge.

But the story of Electric Vehicle batteries is also one of rapid voltage growth. Batteries used in electric vehicles (EVs) were limited to a few hundred volts, but today’s batteries use dozens of volts and continue to improve.

Tesla, the electric car manufacturing giant, has pioneered a new industry with the mass production of electric vehicles. One of their most exciting features is the ability to drive tens or even hundreds of miles on a single charge.

However, one of the biggest challenges with electric vehicles has been the need to recharge Electric Vehicle batteries. Electric car batteries today are nowhere near as powerful as their gasoline counterparts.

Tesla has driven the industry forward when it comes to adopting electric vehicles. As one of the first major automobile manufacturers to begin producing electric cars, Tesla brought the latest battery technology to the industry, which other manufacturers have since adopted.

These days, most new vehicles sold in the U.S. are now electric, with Ford, GM, and Nissan all planning to have at least 10% of their sales come from electric vehicles by the end of this decade.

The Changing cost of EVs is playing a significant role

Batteries are the heart of an electric vehicle, and their cost is a key determinant of overall vehicle affordability. The current cost of lithium-ion batteries has been the main driver of electric vehicle adoption to date.

Still, it’s only a matter of time before the cost of other battery technologies comes down enough to make them more attractive. The cost of installing a battery in an electric vehicle has been by far the biggest constraint on the adoption of electric vehicles.

Analysts at Bloomberg New Energy Finance predict that the price of an electric battery pack will drop to $135 per kilowatt-hour in 2020, from more than $400 today. This drop-in cost is thanks to the rapid scale-up of manufacturing of batteries, particularly for the electric vehicle market. Today, more than half of the $7 billion spent on electric vehicles was on battery production.

EV batteries have been the driving force behind the electric vehicle (EV) revolution. The first generation of Electric Vehicle batteries was expensive, weighing upwards of 170 pounds, were hard to pack, and were limited in terms of range. But over the past few years, the cost of Electric Vehicle batteries has plummeted, and their range has nearly matched gasoline-powered vehicles’ range. EV batteries are now lighter, cheaper, and pack the same punch as their gasoline-powered counterparts.

Conclusion: Electric Vehicle Batteries

The race for the improvement of Electronic Vehicle batteries is a chemical race. And day by day, companies are improving the efficiency of batteries. The innovation process is swift. And that is also important for the betterment of the world.