In woodworking and metalworking, having the right tools can make a big difference in the quality and efficiency of the work. One area that has seen a lot of innovation is custom saw manufacturing. As the need for precision and efficiency grows, the industry has responded with tailored solutions that fit the specific needs of different projects. This means that instead of using a one-size-fits-all approach, craftsmen can now use designed saws for their tasks, leading to better results and a smoother workflow.

Read this article and improve your efficiency using this custom tool.

Understanding Custom Saw Manufacturing

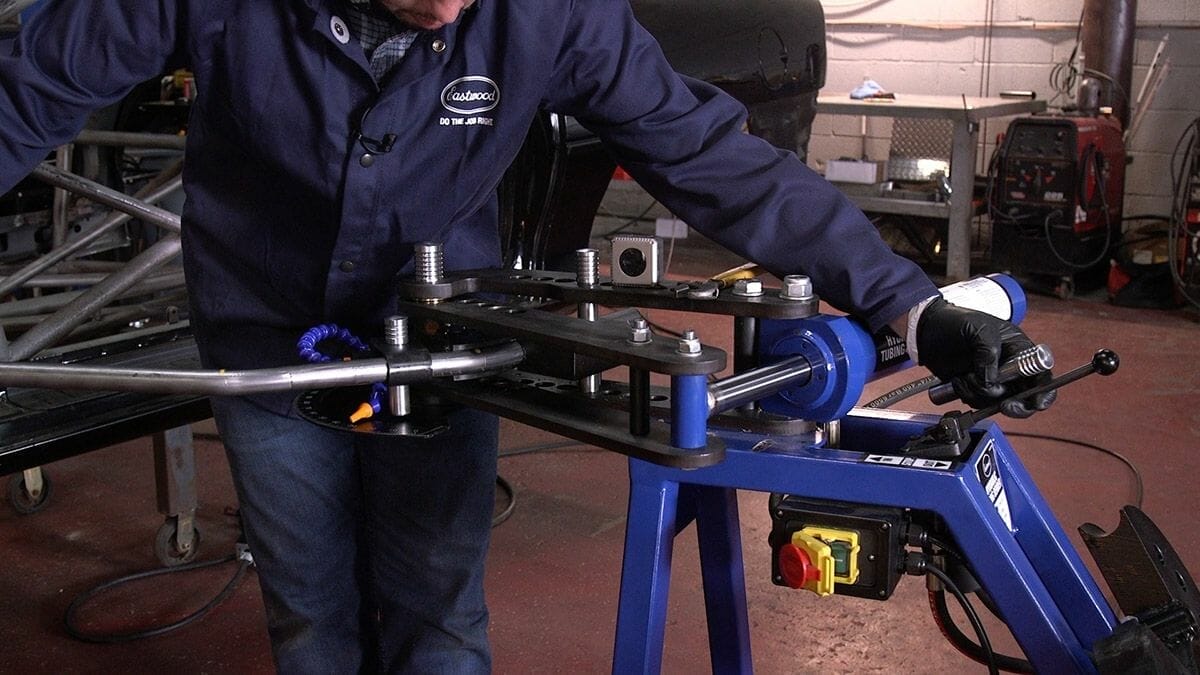

Custom saw manufacturing involves designing and producing saws specifically made to meet the unique requirements of a particular job or material. This process allows for the creation of tools that are optimized for performance, resulting in cleaner cuts, faster completion times, and reduced wear on both the saw and the material being cut.

One company that stands out in this field is Pacific Trail Manufacturing. They have built a reputation for delivering high-quality custom saws that are designed with the user’s specific needs in mind. Their custom approach to manufacturing exemplifies the industry’s move towards more specialized and efficient tools.

The Benefits of Tailored Tools

There are numerous advantages to using custom-made saws. Firstly, they offer improved accuracy. When a saw is designed for a specific task, it can be made to provide the exact cut needed, reducing errors and waste. This is especially important in industries where precision is paramount, such as cabinetry or fine woodworking.

Secondly, custom saws can lead to increased efficiency. By being tailored to the job at hand, these tools can cut through materials more quickly and with less effort, saving time and energy. This is particularly beneficial in high-volume production environments where speed is crucial.

Moreover, using custom saws can extend the life of the tool and the material being cut. By reducing the stress on the blade and the wear on the material, these specialized tools can help last longer, ultimately saving money in the long run.

The Process of Creating Custom Saws

The process of custom saw manufacturing begins with understanding the user’s specific needs. This includes the type of material to be cut, the desired thickness and precision of the cut, and the volume of work to be done. With this information, manufacturers can design a saw that is perfectly suited to the task.

Next, the design is brought to life using advanced manufacturing techniques. This often involves the use of computer-aided design (CAD) software and computer numerical control (CNC) machining to ensure that the final product is as precise as possible. These technologies also allow for a high degree of customization, as adjustments can be made easily to the design if needed.

Finally, the custom saw is tested to ensure that it meets the required specifications and performs as expected. This testing phase is crucial, as it ensures that the tool is safe to use and will deliver the desired results.

Choosing the Right Custom Saw Manufacturer

When selecting a custom saw manufacturer, it’s important to consider several factors. Firstly, look for a company with a strong reputation in the industry. This can give you confidence in the quality and reliability of their products.

Additionally, consider the manufacturer’s experience and expertise in creating custom saws. A company that has been in the business for a long time and has a team of skilled engineers and technicians is more likely to produce a high-quality product.

It’s also important to evaluate the manufacturer’s customer service and support. A good custom saw manufacturer should be willing to work closely with you to understand your needs and provide ongoing support after the sale.

The Role of Technology in Custom Saw Manufacturing

Technology plays a crucial role in the custom saw manufacturing process. As mentioned earlier, CAD and CNC technologies are essential for creating precise and customized tools. These technologies allow for intricate designs and adjustments that would be impossible to achieve manually.

In addition to CAD and CNC, other technological advancements have also impacted the industry. For example, laser cutting and waterjet cutting are now used to create complex shapes and designs in the saw blades, further enhancing their performance.

Moreover, the use of automation in the manufacturing process has increased efficiency and consistency. Automated machines can produce saws faster and with greater precision than manual methods, ensuring that each tool meets the exact specifications required.

Custom Saw Applications

Custom saws find their use in various fields, including woodworking, metalworking, construction, and manufacturing. In woodworking, for example, custom saws are used to create intricate designs and precise cuts in furniture and cabinetry. In metalworking, they are used to cut through tough materials like steel and aluminum with precision and speed.

In construction, custom saws are used to cut materials to size on-site, saving time and reducing waste. In manufacturing, they are used in assembly lines to cut parts to exact specifications, ensuring a perfect fit and finish.

Maintenance and Care of Custom Saws

To ensure that custom saws continue to perform at their best, proper maintenance and care are essential. This includes regular cleaning and lubrication of the saw and its components to prevent rust and wear. It’s also important to check the saw regularly for any signs of damage or wear and to replace any parts that are no longer functioning properly.

In addition, it’s important to use the saw as intended and to follow all safety guidelines to prevent accidents and injuries. By taking good care of your custom saw, you can extend its life and ensure that it continues to provide precise and efficient cuts.

Conclusion

Custom saw manufacturing has revolutionized the way we approach cutting tasks in various industries. By providing tailored tools that are optimized for specific jobs, these specialized saws offer improved accuracy, efficiency, and longevity. Whether you’re in woodworking, metalworking, construction, or manufacturing, investing in a custom saw can elevate your work to new levels of precision and productivity. As the industry continues to evolve, we can expect to see even more innovative solutions that cater to the unique needs of users, further enhancing the capabilities of custom saws.