Different Types of Pipe Benders and Safety Tips

When using any new tool for any kind of project, whether you’re a professional or working on a personal DIY project at home, you will need time to learn how to use the tool. Improper use of equipment is one of the leading and common causes of harmful accidents. When working on a metal project, one of the most valuable tools is a pipe bender, making bending pipes and tubes simpler and more manageable.

Like any other equipment, you first need to know the different types and learn how to operate them safely before using them in your workshop. Knowing how to use pipe benders will not only make your project run smoother but will help you safely use the tools to bend pipes and tubes.

Pipe Bender Explained

The common question is, what is a hydraulic bender? Hydraulic pipe benders are tools generally used to bend tubes or pipes into a desired shape or form. Once a tube or pipe is turned into a particular shape, it is very unlikely or hard to return back into its original shape; however, if you try, you stand a chance of damaging and reducing the quality of the material.

There are other methods of bending tubes and pipes, but using a pipe bending tool allows you to do so with ease and convenience. This equipment is used to bend different materials such as copper, aluminum, steel, and many more, forming different angles and curves. With different pipe bending results, free-standing, ergonomic, mini-pipe, and dual-pipe are a few types of pipe benders available.

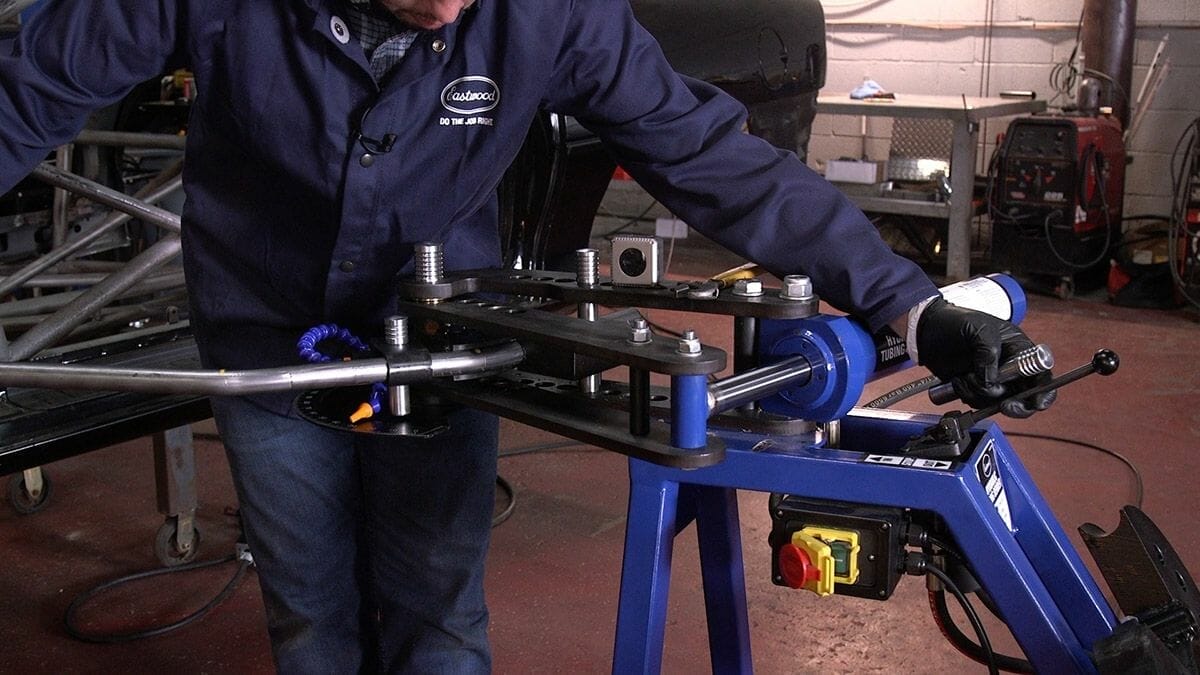

Dual Pipe Benders

The dual-pipe bender is a manually operated bender commonly used to bend pipes to a 90-degree angle, using two handles. After inserting the tube on the equipment and handles, pushing them towards each other causes the pipe to bend. This type of bender is manually operated, which means that it heavily relies on your strength input to turn the tube. Certain kinds of material may not be used on the dual pipe bender, like steel and iron; however, plastic and aluminum pipe are much easier to work with.

Free-Standing and Ergonomic Pipe Bender

The free-standing pipe bender is known as the largest pipe bender, standing on two legs. With a much higher pressure exertion from the operator, the bender allows you to bend thick and larger pipes with two handles. On the other hand, the ergonomic pipe bender is a manually operated tool, with an allowance of bending tubes up to fifteen millimeters, and bends up to 180 degrees, using less force.

Mini and Micro Pipe Bender

Some pipes and tubes are too small to be used on a dual-pipe bender, which can only be bent using mini and micro pipe benders. With three-slot options, a mini pipe bender holds a pipe of a diameter of six, eight, and ten millimeters. Should you have smaller pipes between three to six millimeters, you may need to purchase a micro pipe bender, which also comes in electrical systems.

Conduit Pipe Bender

Made explicitly for conduit pipes, the conduit pipe bender is used for electrical wired and uses one handle, unlike other pipe benders. To leverage for the bending process, this type of bender requires a flat surface like the floor. To use a conduit pipe bender, insert the tube, place the bender on a flat surface, use optimum leverage, and use your feet and handle to bend the tube or pipe.

Also, a more extended handle on the conduit pipe bender offers more leverage on the more rigid material like steel pipes. Should there be wires inside a tube, it is recommended to remove them before the bending process to avoid damaging them.

Pipe Bender Safety Tips

Using any hardware tool poses a level of risk and hazard if not used properly, so it’s recommended to always practice caution whenever using equipment like pipe benders. Where possible, always use protective gear like insulated gloves, goggles, long-sleeve shirts, close-toed shoes, and long pants. Always inspect your equipment for any damages before each use, and if you find any defects, have them fixed and closed before doing any work with the bender.

Avoid improvising and using pipe benders for something other than bending tubes and pipes in the specified diameters and materials. The best way to keep your pipe bender in good condition is regular maintenance, keeping it clean, and stowing it in a dry location like a garage. Although this kind of machine can be costly, it has an ROI in the form of convenience, time, and accuracy over time.