The Fundamentals Of Process Flow: What You Need To Know

When it comes to understanding process flow, many engineers feel overwhelmed. After all, this is a complex topic that can seem daunting at first glance. However, with a basic understanding of the fundamentals, you can start to see how process flow applies to your work and make better decisions when it comes to your projects.

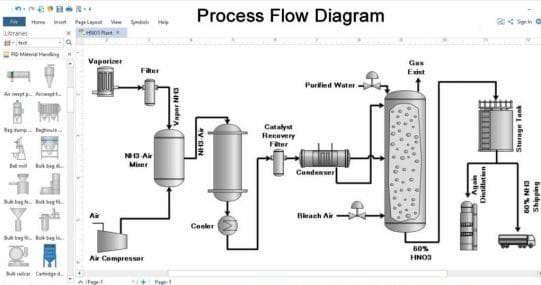

What Is A Process Flow?

The process flow is a visual representation of the steps involved in producing a product or service. It shows how each step interacts with the others, and it can help you identify potential problems and bottlenecks in the production line. In order to create a process flow diagram, you will need to know the following information:

– The name of each step

– The type of step (e.g., input, processing, output)

– The order of the steps

– The dependencies between the steps

Process flow diagrams can be used in various industries, including manufacturing, healthcare, and food service. However, they are most commonly used in the manufacturing sector, where they can be used to improve efficiency and reduce waste.

The Three Main Types Of Process Flow Diagrams

There are three main types of process flow diagrams:

- Flowchart

- Pipe diagram

- Process map

Each type of diagram has its own strengths and weaknesses, and you will need to choose the right one for your project. You can find a chart and graph maker online where you can create your own process flow diagrams. Here is a brief overview of each type:

Flowchart:

A flowchart is a simple way to visualize the steps in a process. It uses symbols such as circles and arrows to show the order of the steps and the dependencies between them.

Piping Diagram:

A piping diagram is similar to a flowchart, but it uses pipes instead of circles to show the flow of material or information between the steps. This type of diagram is helpful for complex processes with many steps and dependencies.

Process Map:

A process map is a more detailed version of a process diagram. It shows how each step interacts with the others, and it can include additional information such as timings and costs.

The Four Steps Of Process Flow

There are four steps:

- Input

- Processing

- Output

- Feedback

Input:

The first step is to gather the raw materials or information needed for the process. This can be done manually or by using a machine or other tool.

Processing:

The second step is to convert the raw materials into finished products. This can involve various tasks such as cutting, welding, and assembling.

Output:

The third step is to send the finished products to the next stage in the production line or to customers/end users.

Feedback:

The fourth step is to collect feedback from customers and use it to improve the process. This can include customer surveys, focus groups, and interviews.

In conclusion, process flow is a complex topic, but it is essential to understand the basics if you want to be an effective engineer. With a basic understanding of process flow, you can start to see how it applies to your work and make better decisions when it comes to your projects.